-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

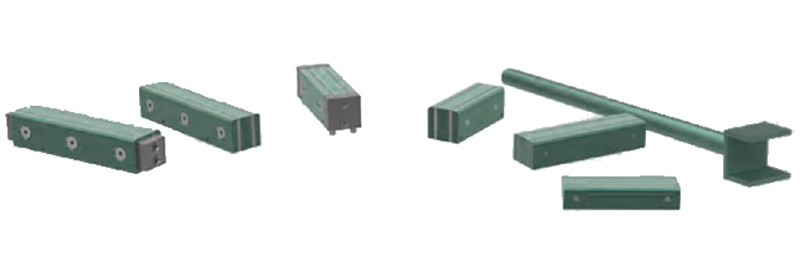

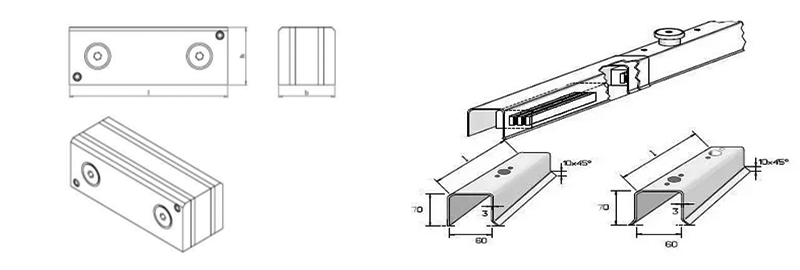

U-profiles Formwork Shuttering Bar Magnet is a magnetic tool specially designed for use in the field of building formwork fixing. It offers a fast fixing solution without drilling or welding. One of the key features of the U-profiles Formwork Shuttering Bar Magnet is its magnet type BR, a magnet developed for transverse and longitudinal stop applications, mainly in combination with U-profiles for the production of prefabricated ceilings and double walls. The magnet must fit the profile 100%. Therefore, BR is available in a large number of different sizes, magnetic forces and designs.

Item No :

U-profiles Formwork Shuttering Bar MagnetOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysU-profiles Formwork Shuttering Bar Magnet

U-profile formwork formwork bar magnets revolutionize the construction process by improving efficiency, versatility and sustainability. Magnetic strips provide fast assembly and disassembly, saving time and effort. The universal compatibility of formwork bar magnets ensures adaptability across a variety of formwork systems. In addition, the use of magnetic solutions can promote sustainable construction practices by reducing waste and maximizing resource efficiency.

1. Suitable for circulation and robotic systems:

- High magnetic force: With strong magnetic force, it can be firmly adsorbed on the metal formwork.

- Lightweight design: Lightweight, easy to carry and operate, reducing the labor intensity of workers.

- Durability: Made of high-quality materials, surface treatment enhances corrosion resistance and durability.

- High temperature resistance: Able to work in high temperature environment, the maximum working temperature can reach 80℃.

2. Suitable for various applications: Suitable for a variety of building formwork fixing scenarios, and can also be used to replace or supplement existing formwork systems.

3. Easy to operate:

- Designed with easy-to-operate release mechanisms such as release levers or buttons, it is convenient and quick to fix and release.

- Magnets can be quickly adsorbed and released, improving work efficiency.

4. Safety:

- Since traditional bolts and nuts are not required, the risk of formwork damage and worker injury is reduced.

- The strong adsorption of magnets ensures the stability and safety of the formwork during construction.

5. Environmental protection:

- Reduces the noise and dust that may be generated in traditional fixing methods.

- Magnets can be reused, reducing construction waste.

5. High-quality materials, compact design and excellent workmanship are the guarantee of high quality and long service life:

- Labor costs and construction time can be reduced due to easy operation and improved efficiency.

- The durability of the magnets means long-term cost-effectiveness.

7. Customizability:

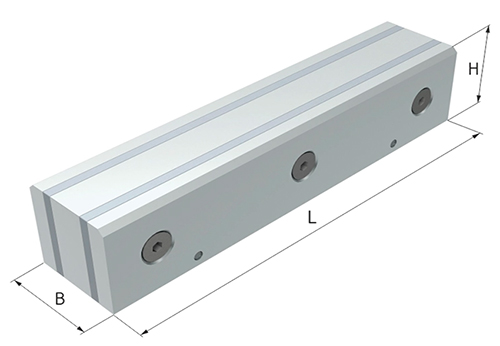

Specification of U-profiles Formwork Shuttering Bar Magnet

| Number | L | b | h | N.W | Force |

| LSC-30/185 | 185 | 50 | 30 | 2.2 | 7500 |

| LSC-40/153 | 153 | 50 | 40 | 2.5 | 7500 |

| LSC-50/97 | 97 | 50 | 50 | 1.7 | 4500 |

| LSC-50/140 | 140 | 50 | 50 | 2.5 | 6500 |

| LSC-50/185 | 185 | 50 | 50 | 3.3 | 8000 |

| LSC-50/230 | 230 | 50 | 50 | 4.1 | 10000 |

| LSC- Release | 2 | 22000 |

Application scenarios of U-profiles Formwork Shuttering Bar Magnet

Our service:

1. Reply to your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in professional and fluent English.

3. Customized design is available. OEM&ODM are welcome.

4. Exclusive, considerate and unique solutions can be provided to our customers by our well-trained and professional engineers and staff.

5. Special discount and protection of sales area provided to our distributor.

Tags :