-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

The precast concrete formwork magnet is one of the most important magnetic components of precast concrete, which mainly functions to fix the side formwork to the formwork platform during the concrete pouring process. With the rapid development of the prefabricated onstruction industry both domestically and internationally, more and more customers are abandoning traditional screw drilling fixation methods and adopting clean and green magnetic fixation solutions. Our template magnet LSC-1350 is a useful and high-tech method for fixing templates to the pouring table. It is made of rare earth material neodymium magnet, which has higher tensile strength than ordinary magnet materials.

The magnet is specially designed with steel on the magnetic part to disperse the magnetic flux and increase the contact area.

The shell surrounds the magnet to prevent damage, or steel can be used to secure the shell to the magnet. Be careful when using magnets to ensure that the bottom and tabletop are clean and free of debris. Due to the large air gap formed between the magnet and the bed, these fragments can cause strength loss.

Item No :

LSC-1350Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10dasy1350KG Precast Concrete Shuttering Magnet:

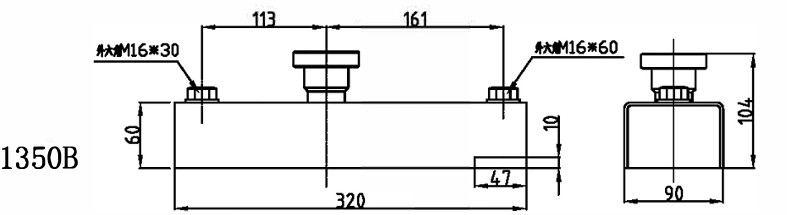

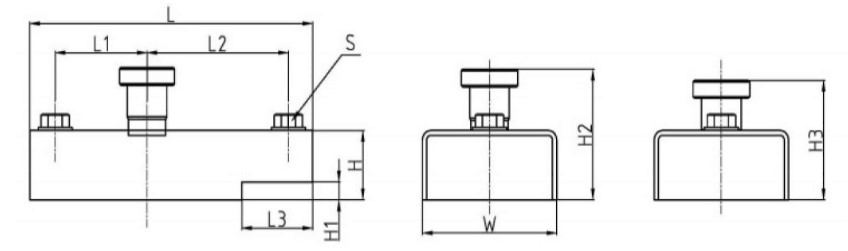

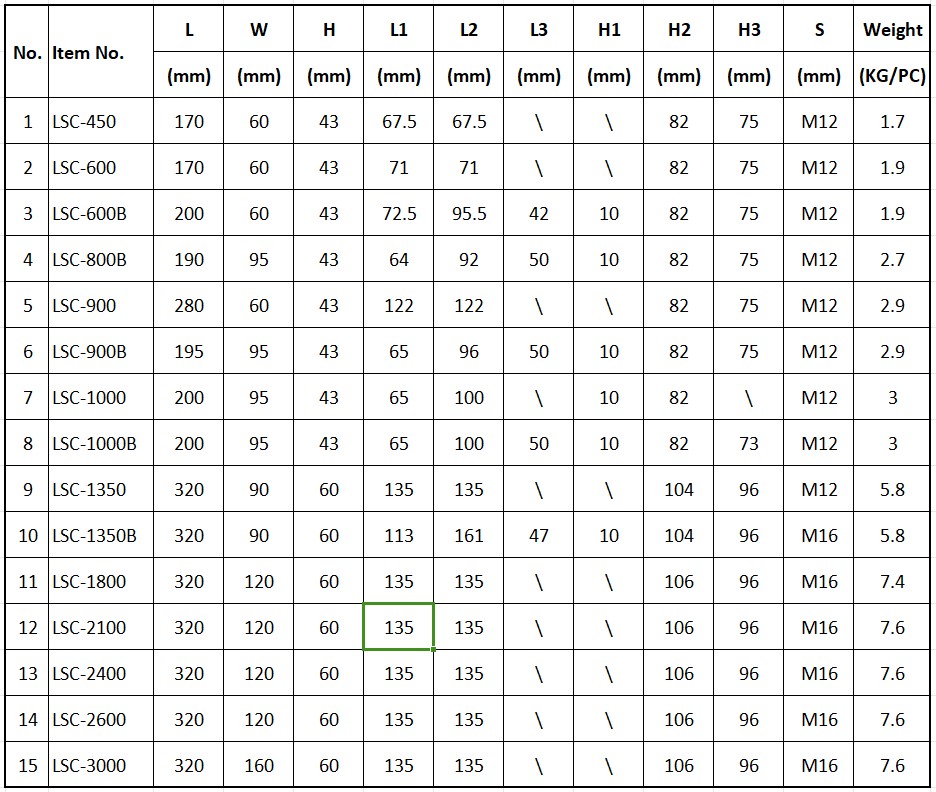

Specification:

Name:Precast Concrete Formwork Magnet, /Prefabricate Concrete Formwork Magnetic Block

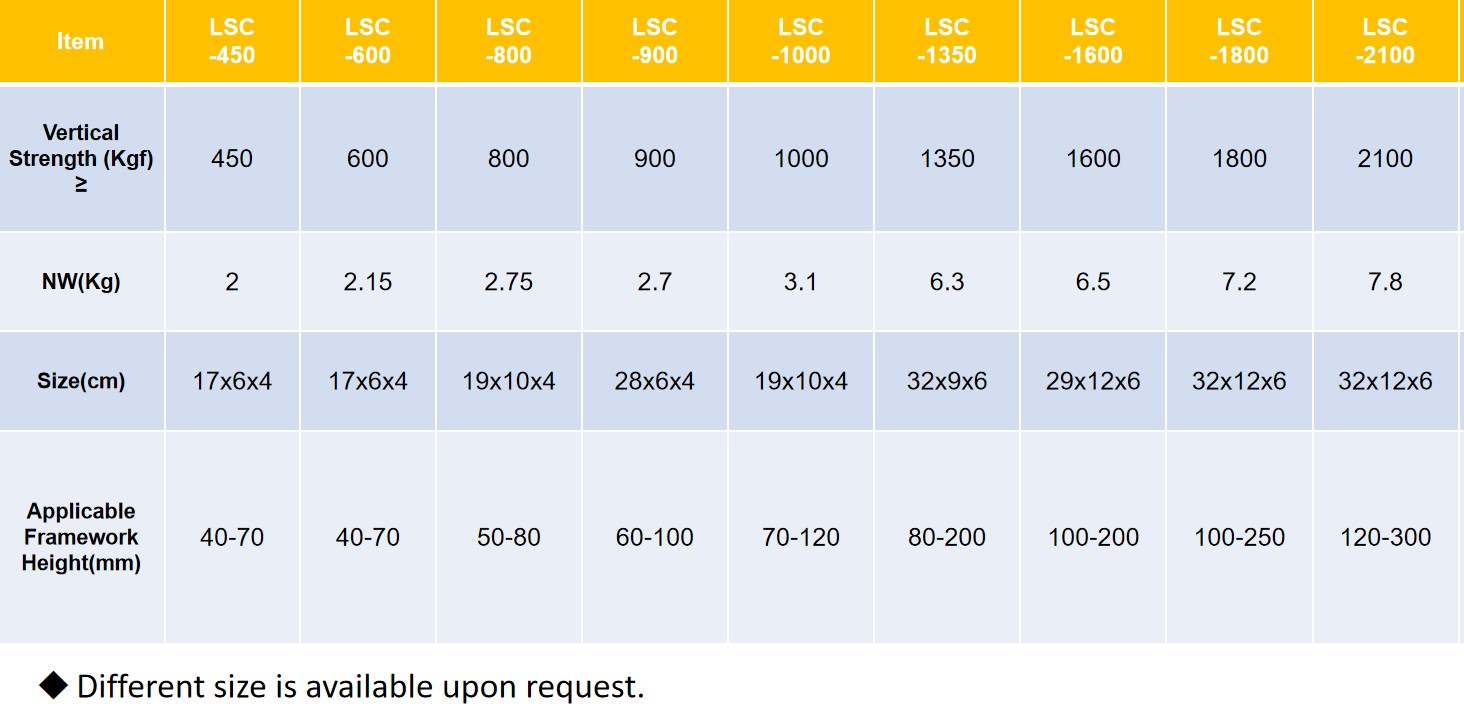

Vertical suction: ≥1350kgs

Size: 320x90x60 mm//Customizable

Material: neodymium magnets + steel

suitable mold height recommended: 80-150mm

Other Model:

Factory of MagFly Shuttering Magnets:

The company has a group of experienced technical R&D personnel and professional production equipment including laser cutting machines, CNC electro-hydraulic bending machines, gantry milling machines, CNC lathes, imported flexible welding platforms, and other professional production equipment to ensure advanced product design, excellent production, and excellent quality. LSC specializes in the production of magnetic boxes and can provide professional customized services according to customer needs to meet the different needs of customers.

Quality Control:

We only produce high quality shuttering magnet , the testing reports will be attached for each shuttering magnet , and will show the testing time , appearance , size , suction power and functionality .

Package of shutter magnet:

Applications of shutter magnet:

Thailand customers use scenarios, we can provide customers with one-stop precast concrete solutions, contact us to get the latest technical information.

1. Prefabricated concrete manufacturers need to pay attention to the usage scenarios of magnetic boxes when selecting template magnets. Please carefully review our standard shutter magnet size.

2. Need to consider whether the forming table is fixed or vibrating, the spacing between steel bars, and the working temperature, etc

The suction force and size of the template magnet should be selected according to the height of the mold that needs to be fixed (the thickness of the prefabricated part).

LSC strives to provide our customers with knowledgeable employees who can provide innovative solutions to meet their needs that will satisfy their needs. In addition to technical support, we are also able to customize precast concrete fittings according to the requirements and designs proposed by our customers.

1. Meticulous quality control

2. High-quality, patented neodymium magnets

3. 24*7 hours online reply

4. Customizable design. OEM and ODM are welcome.

5. Provide special discounts and sales area protection to our dealers.

Tags :