-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

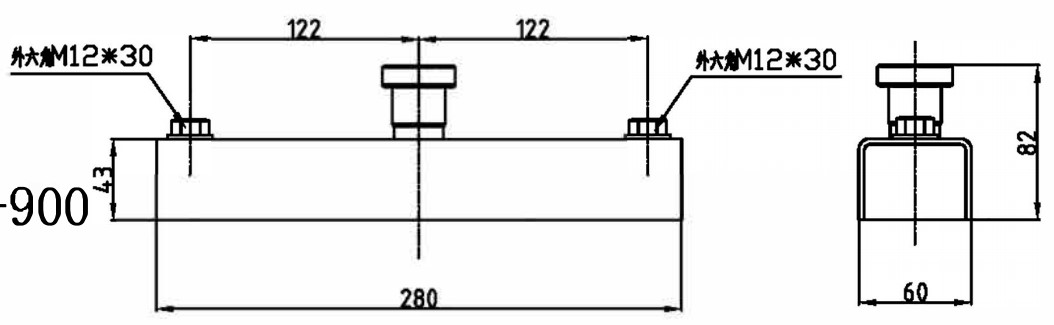

Item No :

LSC-900Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10days900 Kg Shuttering Magnet for Production of Prefabricated Components

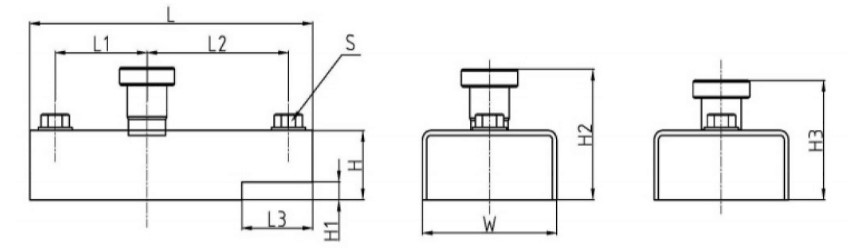

Specification:

Name:Precast concrete magnet / Shuttering magnet

Vertical suction: ≥900kgs

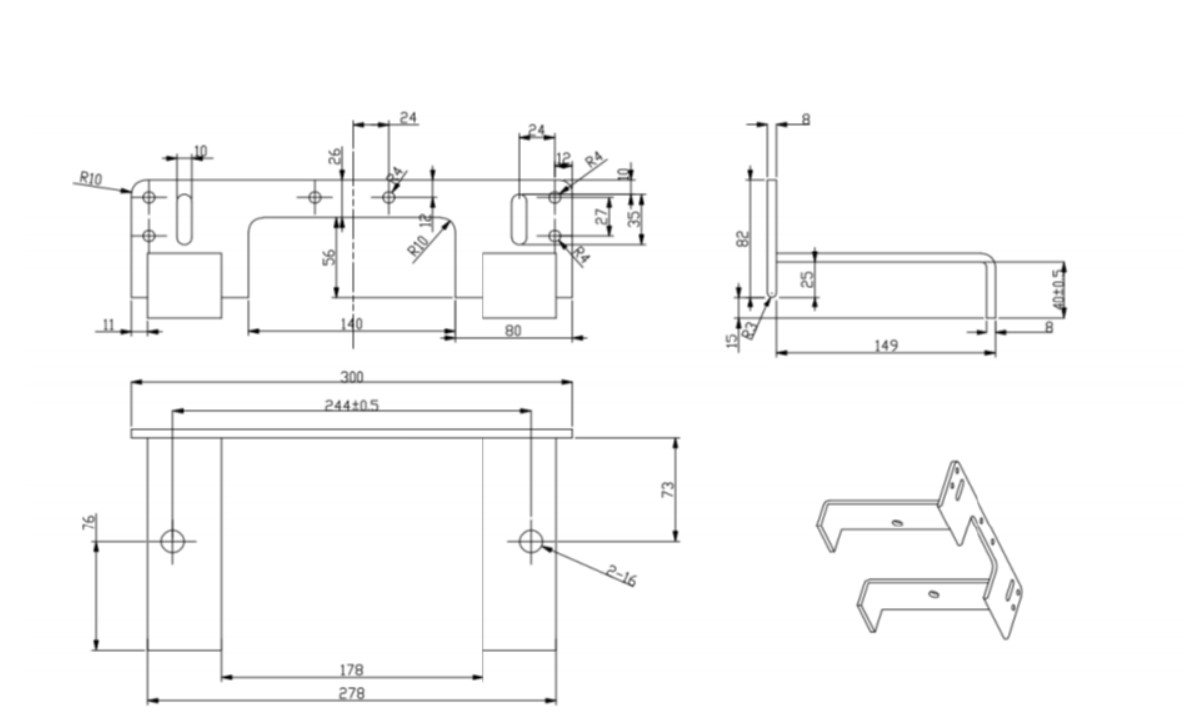

Size: 280x60x43mm/Customizable

Material: neodymium magnets + stainless steel

suitable mold height recommended:50-80mm

Other Model:

Popular selling styles of shuttering magnet are: 1000kg, 1800kg, 2100kg

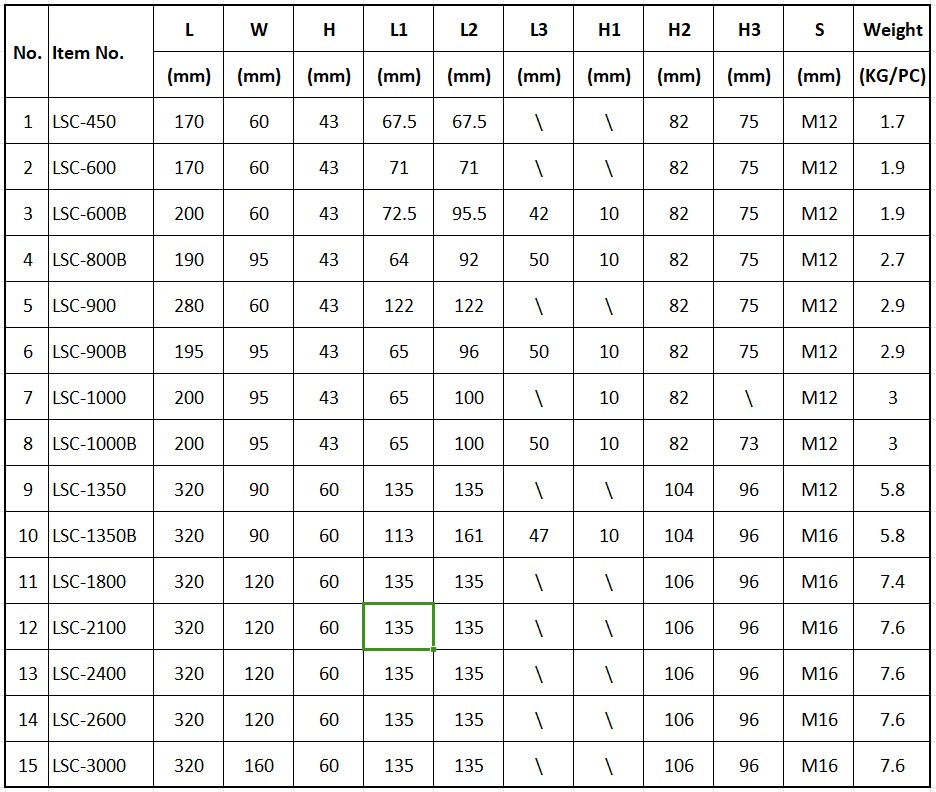

①Magnet on/off Switch:

1. Stainless steel, Lathe fine grinding,

2. Over 100,000 fatigue simulation experiments, avoid any deformation and malfunction.

3. Humanization design, quick switch (on/off) the magnetic field.

②Fixing Screws: (Applicable national standard)

Fixing screws can be utilized to secure different kinds of side rails and blackouts

1. Production according to the standard of GB /T 15389-94-GB.

2. Strength ≤1000 Kg: M12

3.Strength>1000 Kg: M16

③Strong Neodymium Magnet

Many competitors add more than 12% Lanthanum Cerium ingredient in the neodymium magnet when production. 6-8% costs can be saved; by this formula, the same Remanence (Br) is the same as the Chinese standard, but its Coercive Force (Hcb) and Intrinsic Coercive (Hjc) are much less and its magnetic field will decrease about 10-15% after 6-10 months.

Neodymium Magnet occupied more than 50% cost of shuttering magnet. It is the most important element of this product. The most advantage is that Neodymium Magnet is produced and quality controlled by our own since 9 years ago, certificated by GB/T19001-2016 IDT IS09001:2015 and TS16949. Our material is from Shanxi Province, its performance is higher about 1 grade, but expensive a little. Our warranty is 3 years if proper use.

1. Relatively lower price on neodymium magnets.

2. High Grade, N & M Grade.

2. Max operating Temp. ≤ 80℃

3. Anti-Corrosion, high-quality zinc plating.

5. Strong Strength: 450Kg-3500Kg

④Iron casing protection around neodymium magnet:

1. High-quality iron casing.

2. Protection of neodymium magnet from damage when changing the switch.

3. Partly protections neodymium magnet from corrosion and oxygen.

4. Available for easy cleaning of the pneumatic air gun and electric brush.

⑤Plastic Casing:

1. High-Quality ABSF

2. Thermal Stability

3. Wear Resistant

⑥High Quality Spring:

1. Protect Switch

2. Protect magnet from dropping

3. Japanese alloy steel SWOSC-V, by oil quenching; Fatigue resistance, Excellent toughness. Three times strong pressure treatment eliminates internal stress. Surface shot blasting to improve stress concentration strength.

4. The service life of more than one million times.

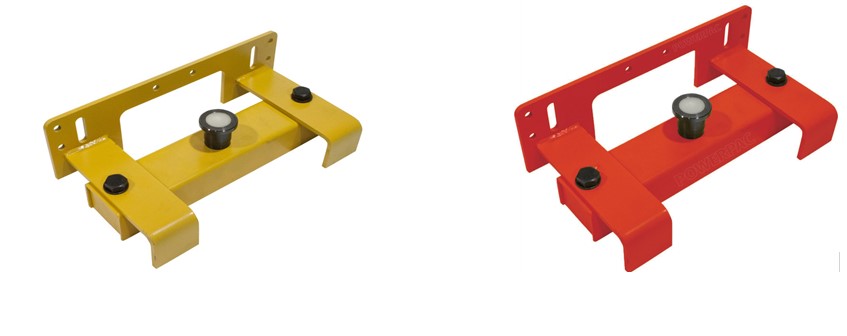

⑦Box Casing: Laser cutting process

1. Stainless steel.

2. Q235: surface blackening treatment

3. Painting, use environmental protection paint, color can be customized.

4. baking varnish, use environmental protection paint, color can be customized.

⑧Stainless steel stud:

1. Strong Fastening

2. Anti-Rust for more than 3 years.

Quality Control:

We also will inspect almost magnet block to ensure each product can reach standard suction.

The following is the suction test report of 900KG Shuttering Magnet:

The clamps can be designed according to customer requirements:

9ookg Concrete Shuttering Magnet application pictures:

Maintenance&Safety Guidelines of Concrete Shuttering Magnet:

(1)In order to avoid the magnet box damaging, do not crash and use hard tools to knock it. Please knock with rubber hammer if must use tools.

(2) Magnet box touching surface should be kept clean and smooth, avoid the scrap iron or concrete grout going inside the box, otherwise the button flexible degree will be affected and the magnet will be slanted, caused the magnet can not be fixed on the platform closely and the suction weakened.

(3)As suction of magnet box is very strong, please avoid closing it to precision instruments,electronic instruments and other iron material. Once they absorb together, it is difficult to separate. Suggest making special tool box to keep them.

(4)Magnet box touching surface should be kept clean and smooth always. And it should be oiled when storage. Max working and storage temperature should be below 80℃,and no corrosive medium around. Always check if the working surface fix the platform closely and the button flexible degree to ensure the normal use.

(5)After using , clean the magnet boxes, and put on stainless steel tool holder. Do not use iron tool holder.

After-Sales Service-Complaint System:

1. Call client within 12 hours.

2. Communicate with client to know what problem happen,

quantity and in which order or batch?

3. Ask clients to take detailed pictures.

4. Internal checking and figure out why problem happened.

5. Offer suitable and satisfying solution, replenishment or refund.

6. Apology and avoid problem in future orders.

Tags :