-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Shuttering Magnet consists of Neodymium Magnet with push down- up handle button. Concrete magnet boxes retain enormous magnetic force and are widely used in concrete precast industries. The use of concrete magnets is very simple. just push the button down and the concrete magnet will firmly catch with the steel frames. Use a lifting lever tool when removing the concrete magnet.

Using our expertise in magnetic components and experience in supporting for the prefabricated building industry, we have already developed magnetic shuttering for precast concrete production.

Item No :

LSC-450Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10days450 Kg precast shuttering magnet for Production of Prefabricated Components

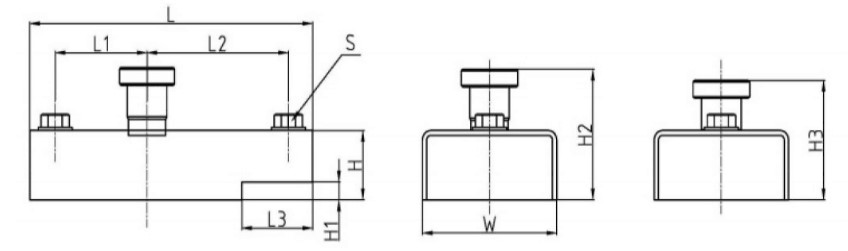

Specification:

Name:Precast concrete magnet / Shuttering magnet/Push-Button Magnet

Vertical suction: ≥450kgs

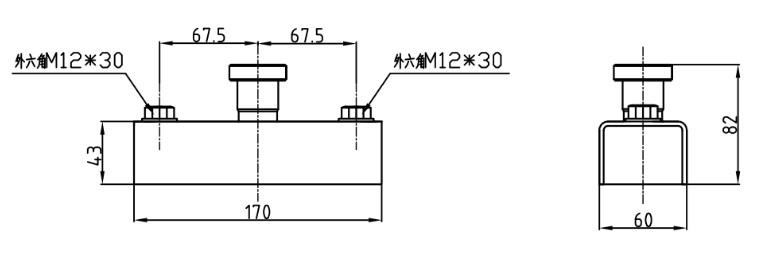

Size: 170 x 60 x 43 mm/Customizable

Material: stainless steel/ Q235 steel

suitable mold height recommended: 40-70mm

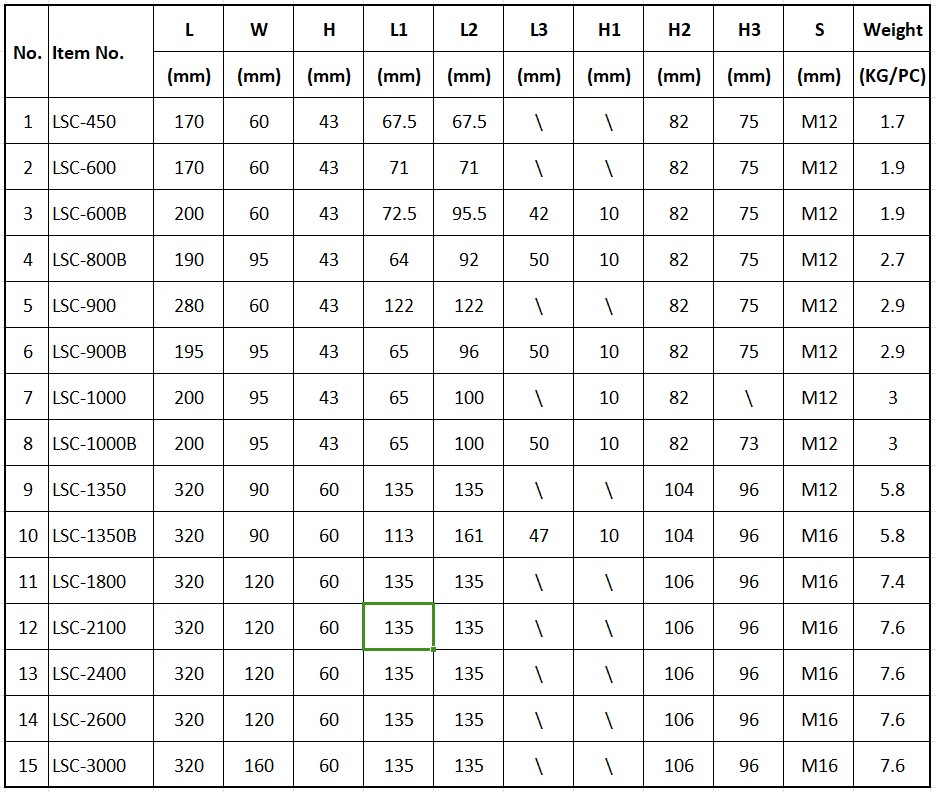

Other Model:

Popular selling styles of shuttering magnet are: 1000kg, 1800kg, 2100kg

Key Benefits Of Precast Magnets:

1. Reducing the complexity and time of the installation of formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece products of all forms on the same steel table.

3. Eliminates the need for welding, shuttering magnets does not damage the steel table.

4. Makes it possible to produce radial products.

5. A small cost of a set of magnets. The average payback of about 3 months.

6. The main advantage of the shuttering magnets is that you do not need to have a lot of different forms for different products, you need to have a set of magnets, adapters for different height boards and steel table.

Factory of Shuttering Magnet:

Our factory has over 30 people working on the production line. We can produce 1000 louver magnets every day. We can produce shuttering magnet 1000pcs each day .So we can arrange shipment for you within 7-10 days.

Quality Control:

We also will inspect almost magnet block to ensure each product can reach standard suction .

The following is the suction test video of LSC-450:

How to Pack a Shuttering Magnet, to Meet Your Requirements Shipping by Sea, by Air/Express, and Railway?

Your shuttering magnet will pack with a double-wall corrugated carton firstly and tight with a strong packing belt. Between cartons and shuttering magnet, between magnets, there is a high-quality foam plate to separate and protect products from scratch and damage.

1. By Sea, you have 2 packing options by sea.

1.1 Packing by Pallet

1.2 Packing by Strong Wooden Case.

This option looks more formal and beautiful. But it is more expensive 35USD per Case than option 1.

2. What Should You Pay Attention to When Shipping Shuttering, Agents by Air?

By Air and Express such as FedEx, DHL, UPS, and TNT:

In international air/Express transportation, magnetic items are sensitive, and their magnetism will interfere with the safety of aircraft transportation. Therefore, the airline decided that all items containing magnetism need to be magnetically inspected.

So we need to magnetically shield the items so that the magnetism of the items meets airline standards. So packing needs to insert thick iron sheets or iron boxes between the foam and carton wall.

Friendly tips:

● When magnetic items are shipped together with non-magnetic items, all items must be checked for magnetism.

● The magnetic inspection report is a one-time report and is only used once. Next time, even if you use the same logistics channels for the same items, you still need to do a magnetic inspection and obtain the corresponding magnetic inspection report. Except for FedEx and DHL, they accept annual magnetic reports.

● By Railway, we use the same packing standard as that of by air.

45okg Concrete Shuttering Magnet application pictures:

Precast concrete magnet box is designed for fixing precast concrete shuttering .

Tags :