-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

The precast concrete shuttering magnet is one of the most important precast concrete magnetic components, and its main function is to fix the side formwork to the formwork table during the concrete pouring process. With the rapid development of the prefabricated construction industry at home and abroad, more and more customers abandon the traditional fixing method of screw drilling, and adopt clean and green magnetic fixing solutions. Combining our many years of experience in supplying foreign customers, we According to the actual production requirements of customers, magnetic boxes of various specifications are designed for customers to choose, such as 600 kg, 800 kg, 1000 kg, 1350 kg, 2100 kg, etc.

Item No :

LSC-1000Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10days1000KG Precast Concrete Shuttering Magnet

Specification:

Name:Shuttering Magnet for Concrete Formwork System/Precast Concrete Magnets for Architecture Buildings

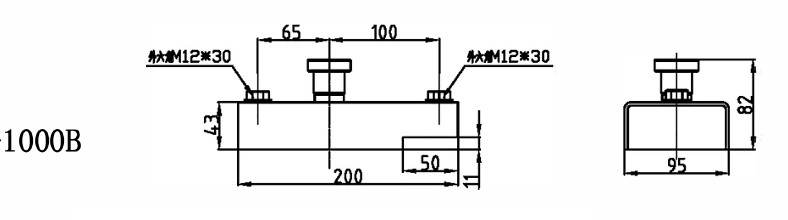

Size: 200x95x43mm/Customizable

Material: neodymium magnets + stainless steel

suitable mold height recommended: 60-100mm

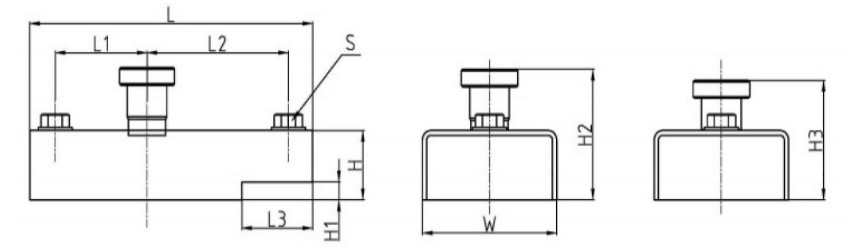

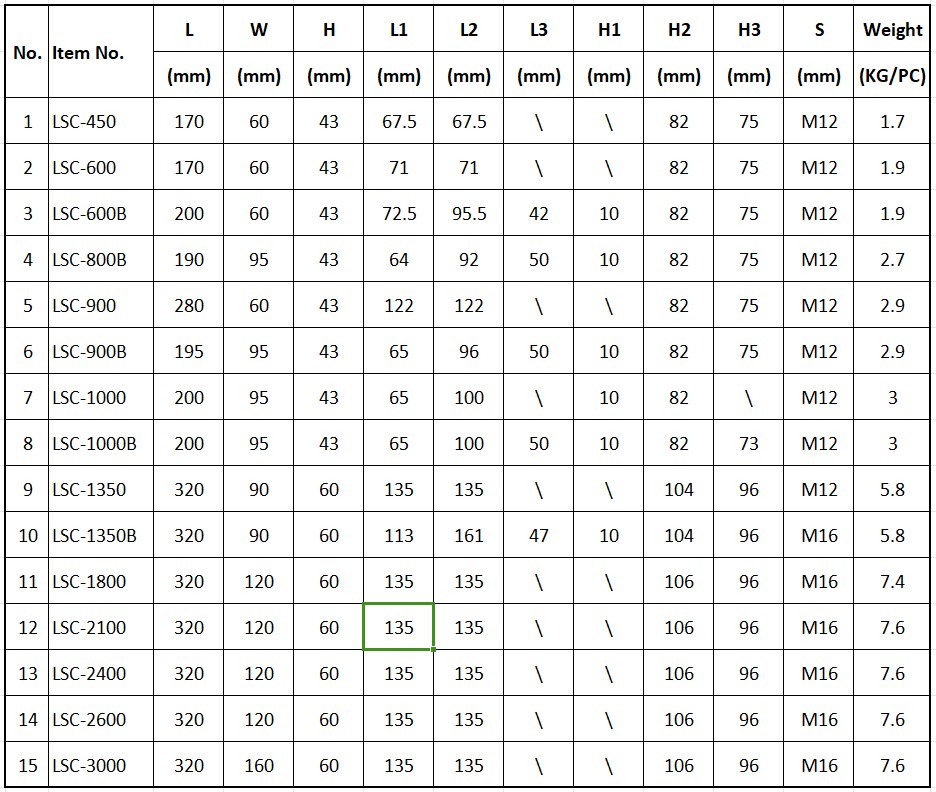

Other Model:

Advantage of Shuttering Magnet:

(1). German quality, but price is cheaper than Ratec at least 50%.

(2) LSC-2100kg is most popular in Europe. Our main clients are from the U.K.,

Poland, Slovenia, France and etc.

(3). Regular & hot selling models, in stock. Fast shipment.Meet the urgent needs of

the customers.

(4). One-stop service, our service has been on the road and there is no finish.

Factory of Shuttering Magnet:

Our Factoy has a complete quality control system, including complete quality inspection documents, inspection equipment and professional inspection personnel. It strictly controls the incoming inspection of raw materials, production process control and finished product inspection before leaving the factory to ensure that the pass rate of products is over 99%. Professional customized services can be provided according to customer needs to meet the different needs of customers.

Quality Control:

We also will inspect almost magnet block to ensure each product can reach standard suction .

The following is the suction test video of LSC-1000:

Precast Concrete Shuttering Magnet Packaging&Loading:

1. Usually put 2 or 3 pcs product in one carton

2. Each box is fixed with packing belt

3. Usually use pallet and plastic film for wrap-up to secure the cargo inside safe and sound

4. The outer frame is fixed with wooden case and ship out .

Application of Shuttering Magnet:

Precast concrete magnet box is designed for fixing precast concrete shuttering.

Working Principle of Shuttering Magnet:

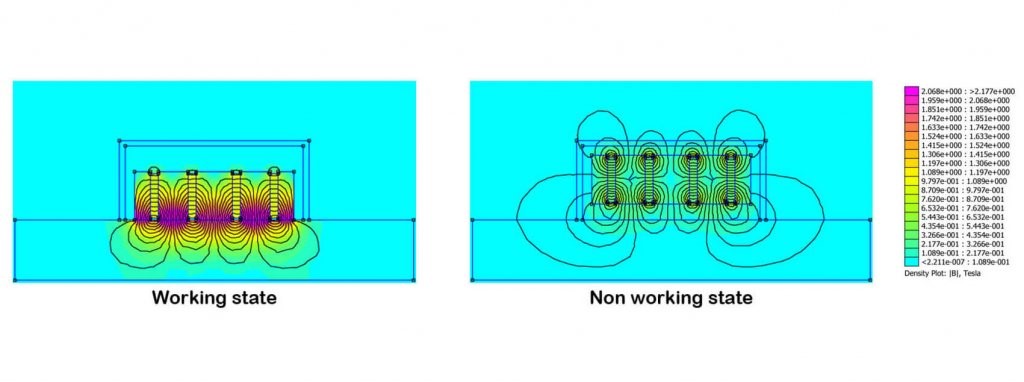

The shuttering magnet is a combination of neodymium iron boron and magnetic conductive sheet with huge suction, which is the core part of the magnetic box. When you press the button of the magnetic box, it releases a huge suction force. Of course, the suction force of the magnetic box is also affected by the smoothness, distance and thickness of the surface of the mold table.

How to use and store Shutting Magnet?

1. In the use of Precast Concrete Magnet, debris should be avoided at the bottom, affecting the adsorption force of Precast Concrete Magnet and mold bases.

Our company's Precast Concrete Magnet is made of high-performance rare earth permanent magnets and produce strong magnetic adsorption in the magnetic circuit.

When the Precast Concrete Magnet is in working condition, the suction surface at the bottom of the magnetic block closely fits on the steel die platform and is firmly held. However, when foreign matter (such as concrete, grease, and thin film) at the bottom of the magnet block cannot be brought into close contact with the platform, the holding force will be significantly reduced.

2. Cleaning advice

Before using the Precast Concrete Magnet, check matter whether the bottom of the magnetic block and the platform are clean and flat. If there is a foreign on the bottom of the Precast Concrete Magnet, it can be cleaned with a stainless steel scraper (the iron scraper will be adsorbed and cannot be cleaned). If there are concrete or other substances that cannot be cleaned easily, it can be cleaned with a grinder. As shown in the figure below, the wire polisher is installed on the grinder and the bottom of the magnet is polished.

3. Gently handle, to prevent the magnet inside the Precast Concrete Magnet damaged

Because the high-performance permanent magnet material used for magnets is sintered from rare earth materials, its texture is similar to that of ceramics, it is hard and brittle, and it is easy to crack.

Therefore, during the use of Precast Concrete Magnet, it is necessary to prevent them from being thrown or snagged, and they cannot be thrown at a long distance when the mold is removed. Avoid the use of hard tools (such as iron hammer) knocking, bruising, etc., resulting in Precast Concrete Magnet deformation.

4. Precast Concrete Magnet collection suggestions

After the Precast Concrete Magnet is used, it should be cleaned and placed on the stainless steel cart to keep the Precast Concrete Magnet clean and convenient for the next use. Precast Concrete Magnet should not be placed on iron cars so as not to suck them up.

5. Magnetic storage recommendations

The ambient temperature used and stored in the Precast Concrete Magnet should not be higher than 80°C, and there should be no corrosive medium such as strong acid or alkali.

In summary, as long as the above measures for protection, clean-up, and prevention of knocking are carried out, we believe that LSC's Precast Concrete Magnet must be durable and trustworthy!

Tags :