-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

As an important accessory of precast concrete system, precast concrete magnets are used to fix panels when pouring concrete molds, especially 2100KG precast concrete magnets are the most used size among all products in European and American countries.

Prefabricated Concrete Magnet is suitable for all formwork constructions like steel and plywood formwork systems with appropriate adapters as it consists of permanent strong permanent magnets (neodymium magnets) in shielded steel or iron boxes. The staff can control the on/off of the magnetic adsorption force by pressing the button above the middle of the magnetic box. On-site operation is very simple and convenient.

The new precast concrete technology has many advantages over the old cast-in-place model. Thanks to these excellent performances, the green business economy is being adopted by many construction companies as a new way of working in Europe, South America, India and now also in China. With the development of precast concrete technology, it has been widely used in floors, walls and even roofs from private houses to giant buildings, with higher durability, flexibility and economy.

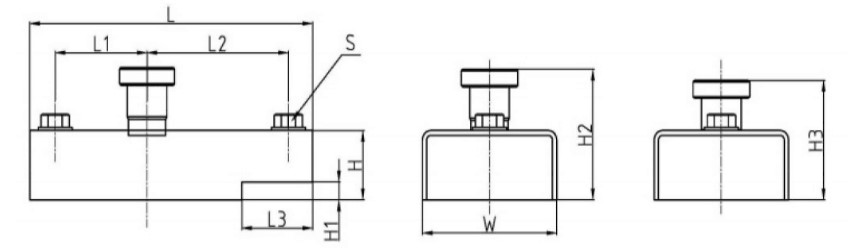

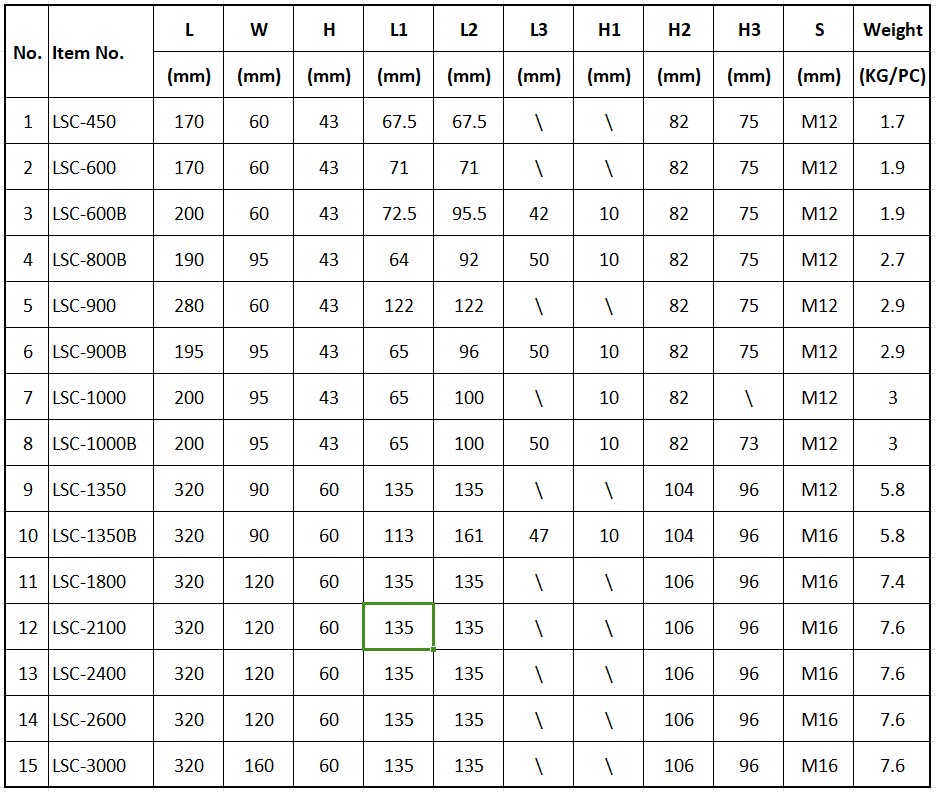

The suction force of the magnetic box we provide is from 450-3000KG. There are various styles and can be customized.

Item No :

LSC-2100Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10days2100KG Precast Concrete Shuttering Magnet

Specification:

Name:Precast Concrete Formwork Magnet/Push-Button Magnet/Precast concrete magnet

Vertical suction: ≥2100kgs

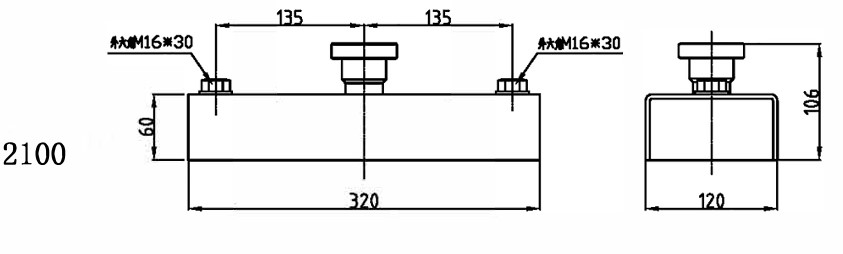

Size: 320x120x60mm/Customizable

Box material: neodymium magnets + steel

Suitable mold height recommended: 120-300mm

Other Model:

Factory of Shuttering Magnet:

Our Factoy has a complete quality control system, including complete quality inspection documents, inspection equipment and professional inspection personnel. It strictly controls the incoming inspection of raw materials, production process control and finished product inspection before leaving the factory to ensure that the pass rate of products is over 99%. Professional customized services can be provided according to customer needs to meet the different needs of customers.

Factory Stock:

We have various styles of magnetic boxes, which can be customized, with large stocks and fast production speed, fast delivery time, guaranteed quality and competitive prices.

Quality Control:

We also will inspect almost magnet block to ensure each product can reach standard suction .

The following is the suction test video of LSC-2100:

How to Pack a Shuttering Magnet, to Meet Your Requirements Shipping by Sea, by Air/Express, and Railway?

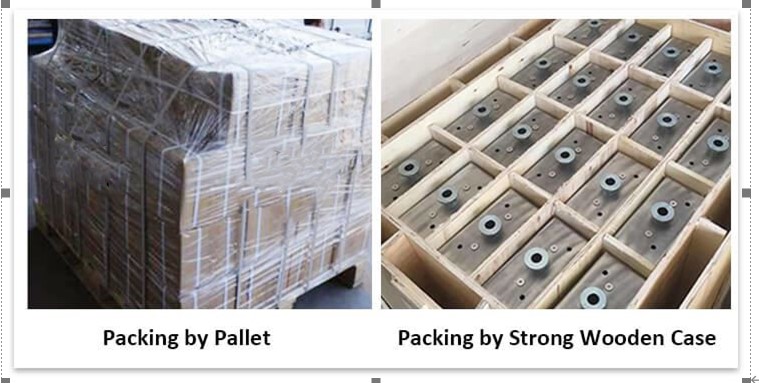

Your shuttering magnet will pack with a double-wall corrugated carton firstly and tight with a strong packing belt. Between cartons and shuttering magnet, between magnets, there is a high-quality foam plate to separate and protect products from scratch and damage.

1. By Sea, you have 2 packing options by sea.

1.1 Packing by Pallet

1.2 Packing by Strong Wooden Case.

This option looks more formal and beautiful. But it is more expensive 35USD per Case than option 1.

2. What Should You Pay Attention to When Shipping Shuttering, Agents by Air?

By Air and Express such as FedEx, DHL, UPS, and TNT:

In international air/Express transportation, magnetic items are sensitive, and their magnetism will interfere with the safety of aircraft transportation. Therefore, the airline decided that all items containing magnetism need to be magnetically inspected.

So we need to magnetically shield the items so that the magnetism of the items meets airline standards. So packing needs to insert thick iron sheets or iron boxes between the foam and carton wall.

Application of LSC-2100KG Strength of Shutter magnet:

About Shuttering Magnet Adapter:

Shuttering magnets typically use custom adapters to fit the steel plate.

Maintenance of Shuttering Magnets

First, In the use of the shuttering magnet:

It should avoid any debris at the bottom of the table, affecting the magnetic force of the shuttering magnet too much and the mold table. We use high-performance rare earth permanent magnet materials to produce strong magnetic attraction in the magnetic circuit. When the shuttering magnet is in the working state, the suction surface at the bottom of the magnetic block is closely attached to the steel mold platform and is firmly held. However, when there is a foreign matter (such as concrete, grease, or film) at the bottom of the magnet block, it cannot be closely attached to the platform, and the attraction power will be significantly reduced.

To this end, we take the LSC-1000 shuttering magnet as an example to research the relationship between the holding force and the bottom of the magnet block and the platform clearance. We placed 0~10 sheets of A4 paper (the thickness of each sheet is 0.09mm) between the bottom of the magnet block and the platform to test the adsorption force of the shuttering magnet under different gaps. The test data is as follows:

As can be seen from the above figure, the gap between the bottom of the magnet block and the platform will significantly affect the holding capacity of the shuttering magnet, so we recommend that the customer maintain the shuttering magnet as follows:

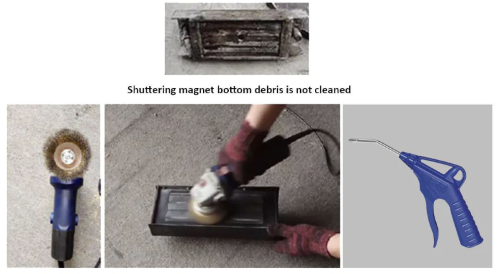

Secondly, clean the debris on the bottom and the debris on the table:

Before using the shuttering magnet, make sure the bottom of the magnetic block and the platform are clean and flat. If there is a foreign matter at the bottom of the shuttering magnet, it can be cleaned with a stainless steel scraper (the iron scraper will be absorbed and cannot be cleaned). If there is concrete, it is difficult to clean the material. At the time, it can be cleaned with a polishing knife. As shown in the figure below, the wire polishing plate is installed on the sander to polish the bottom of the magnet block.

We cleaned it with a pneumatic air gun if you have one.

Third, gently take care to prevent damage to the magnet inside and the shuttering magnet:

As the high-performance permanent magnet material used is sintered by rare earth materials, it is hard and brittle, and it is easy to be broken, similar to ceramics, Therefore, during the use of the shuttering magnet, it should be prevented from falling and chaos, and it cannot be thrown at a long distance after it removes from the mold. Avoid using a hard tool (such as an iron big hammer) to knock, bump, etc., causing the shuttering magnet to deform. As shown below:

Fourth, the shuttering magnet collection:

After the shuttering magnet is used, the shuttering magnet should be cleaned and placed on the stainless steel cart to keep the shuttering magnet clean for convenient use. The shuttering magnet should not be placed on the iron cart to avoid it being caught and cannot move away.

Fifth, shuttering magnet storage:

1. When the shuttering magnet is not used for a long time, after the shuttering magnet is cleaned, apply anti-rust oil (such as Mobil, Great Wall, etc.) at the bottom of the shuttering magnet to prevent the magnet block from rusting and affect the holding power.

2. The ambient temperature of the shuttering magnet used and stored should be no higher than 80 °C, and there is no corrosive medium such as strong acid or alkali. In summary, as long as the above protection, cleaning, and prevention of knocking, etc., I believe that the shuttering magnet of Zhangzhou LSC Magnetics Co.,Ltd.. will be durable and trustworthy!

Tags :