-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Precast concrete magnets are a useful and high-tech method of fixing formwork to the casting bed. They are made from rare earth materials, which give higher pull-off strengths than other magnet materials. The magnets are designed so that the magnetic portion is layered with steel to spread the magnetic flux and thereby increase the contact area. Housings then surround the magnet to protect against damage, or the steel may be used to bolt a housing to the magnet. Care should be taken when using the magnet to ensure the base is clean and free from debris. This debris causes a loss of strength due to a large air gap forming between the magnet and the bed.

Item No :

LSC-800Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10days800 Kg precast shuttering magnet for Production of Prefabricated Components

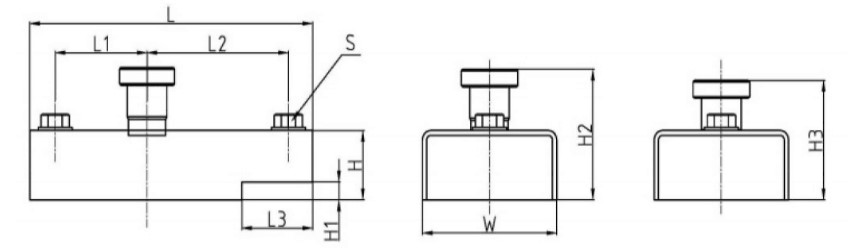

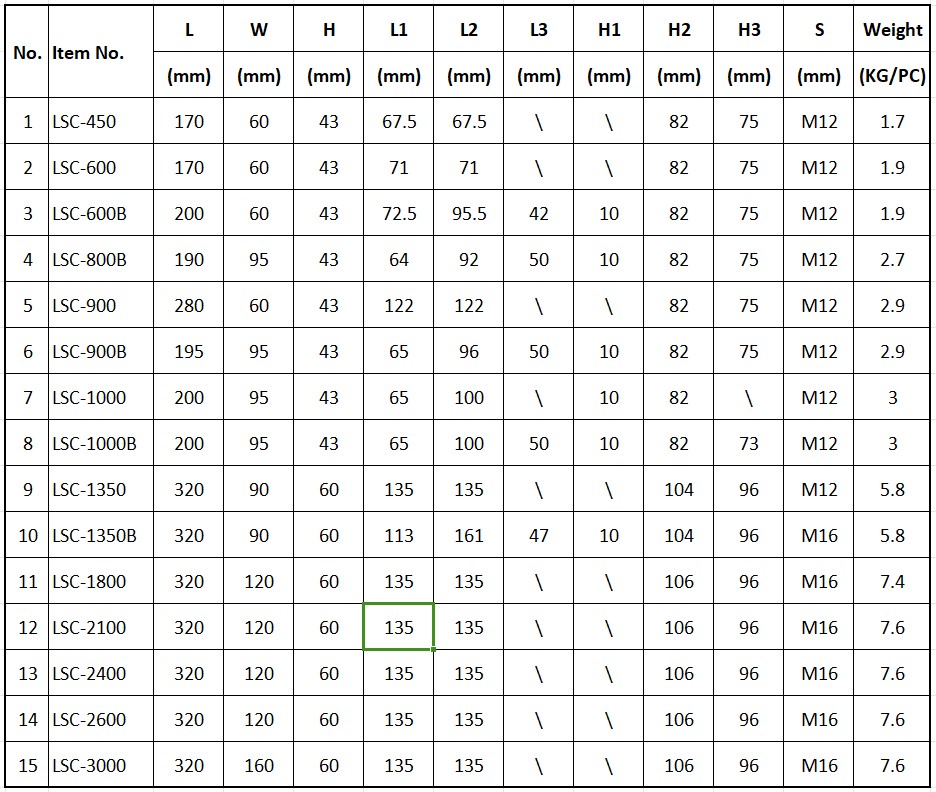

Specification:

Name:Precast concrete magnet / Shuttering magnet/Push-Button Magnet

Vertical suction: ≥800kgs

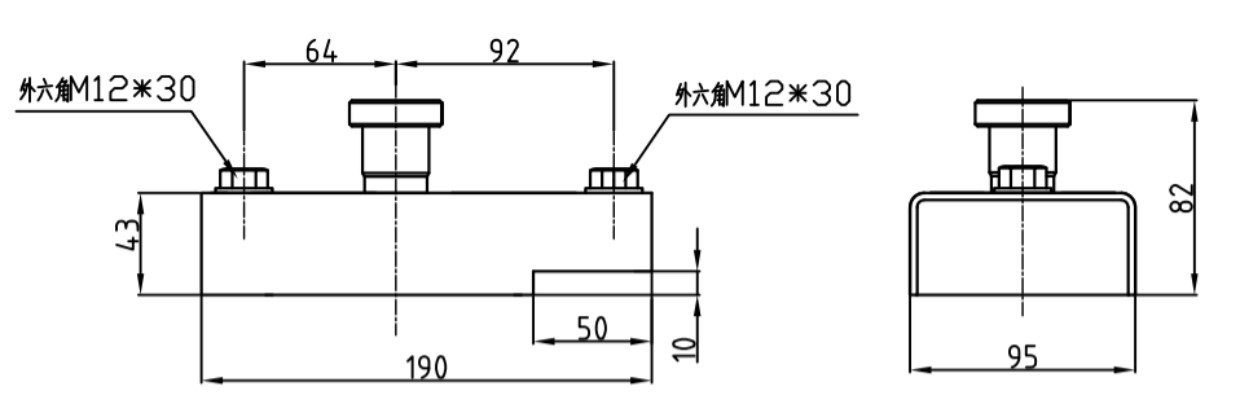

Size: 190x95x43mm/Customizable

Material: neodymium magnets + stainless steel

suitable mold height recommended: 50-80mm

Other Model:

opular selling styles of shuttering magnet are: 1000kg, 1800kg, 2100kg

Factory of Magnet for Precast Formwork:

Our factory has a group of experienced technical research and development personnel and professional production equipment including laser cutting machines, CNC electro-hydraulic bending machines, gantry milling machines, CNC lathes, imported flexible welding platforms, etc., to ensure advanced product design, excellent production, and excellent quality. And can provide professional customized services according to customer needs to meet the different needs of customers.

The most important and fundamental aspect of high-quality Shuttering Magnet is to ensure that the suction force meets the standard.

Do you know that the suction of the 800 kg magnetic box you purchased is really 800 kg? Is the suction force of the magnetic box you purchased really the same as the suction force value specified in the contract?

The following video shows the suction detection data tested by our company using professional testing instruments:

Material:

(1) Magnet: The magnet is the core raw material of the shuttering magnet. For the shuttering magnet, there are two main properties that are crucial:

①Remanence(Br): First magnetize the ferromagnetic material and then remove the magnetic field. The remaining magnetization intensity on the magnetized ferromagnet directly affects the suction of the shuttering magnet. The higher the magnet performance, the greater the Br.

②Coercive force (Hcj):Intrinsic coercivity is a major indicator of the ability of a permanent magnetic material to resist external reverse magnetic fields or other demagnetizing effects to maintain its original magnetization state. It directly affects the degree of decay of the magnet performance when it is affected by the external environment (such as reverse magnetic field, high temperature, etc.). The larger the Hcj, the stronger the resistance to decay.

The performance parameters of the magnet used by Zhangzhou LSC Magnetics Co.,Ltd. meet the GB/T 13560-2017 "Sintered NdFeB Permanent Magnet Materials" standard requirements. Hcj of N35 is not less than 12KOe, Br is not less than 12.1KGs; Hcj of N50 is not less than 13.9KOe, Br is not less than 12.1KGs.

① The bottom of the magnetic box inevitably adsorbs attachments such as iron wires and debris on the mold table during operation, resulting in a decrease in the suction force of the magnetic box during operation. For this purpose, our company has developed a magnetic box cleaning machine specifically for cleaning the bottom of magnetic boxes to solve this problem.

② On the other hand, due to structural reasons, if the production process is not well controlled, the magnetic block itself may also cause misalignment of the iron bars (uneven suction surface), resulting in a decrease in magnetic box suction.

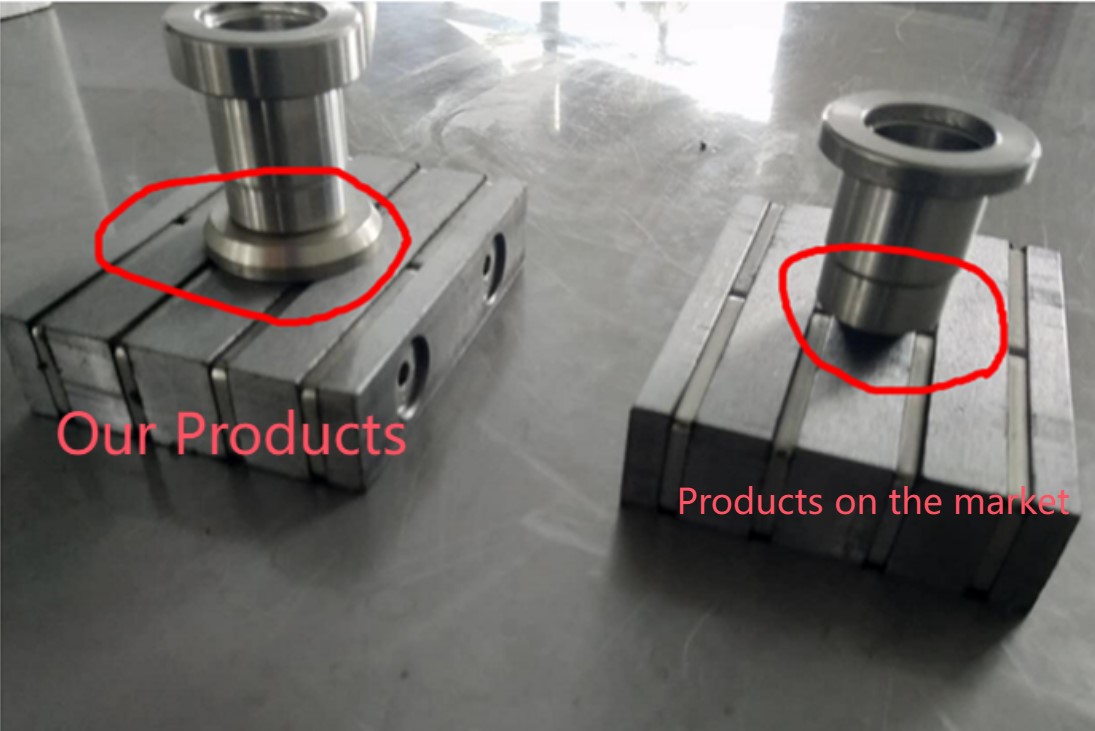

Our Shutting Magnet has added stainless steel pads between the magnetic core and the magnetic switch, increasing the contact area between the magnetic core and the magnetic switch, preventing unevenness inside the magnetic core during the Shutting Magnet switching process, and avoiding a decrease in Shutting Magnet suction force.

During the leveling process of our magnetic block, the stainless steel locking screws inside the magnetic block use a standard fixed torque wrench, set the torque value, and stop when the fixed torque value is reached, so that the torque of each screw is the same, ensuring the tightness and uniformity of the magnetic block and extending its service life.

The physical properties of sintered neodymium iron boron materials are hard, brittle, fragile, and prone to corrosion, so the magnet cannot be struck with external force and the coating on the surface of the magnet cannot be damaged. If the magnet inside the magnetic block breaks and the body is damaged, the suction force of the magnetic block will decrease.

So when assembling magnets and iron bars into magnetic blocks, the surface of the magnet should be as low as possible below the plane of the iron bar to effectively avoid impact, and the magnet itself also needs a certain protective layer to prevent damage and corrosion to the body.

In order to protect the magnet body, our company adopts the latest technology to cover each magnet with a stainless steel ring, and through welding and tapping, the stainless steel ring and magnet are tightly adhered:

Thailand customers use scenarios, we can provide customers with one-stop precast concrete solutions, contact us to get the latest technical information.

Our service:

1. Reply to your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in professional and fluent English.

3. Customized design is available. OEM&ODM are welcome.

4. Exclusive, considerate and unique solutions can be provided to our customers by our well-trained and professional engineers and staff.

5. Special discount and protection of sales area provided to our distributor.

Tags :