-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic Shuttering Solutions For Precast Concrete Formworks,Precast Side Form Magnetic clamp 1oookg, Shuttering Magnet Mayfly,Universal Magnet, Magnetic Box Clamping Magnet, Side-forms Holding Magnets, SUPER STRONG LIGHTWEIGHT MAGNET, high retaining force standard magnet, Tailor-made Concrete Formwork Magnet China Supplier.

Item No :

MagFly Magnet Compact Solution for Positioning Magnetic Force 2000kgOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysFeatures of MagFly Magnet Compact Solution for Positioning Magnetic Force 2000kg

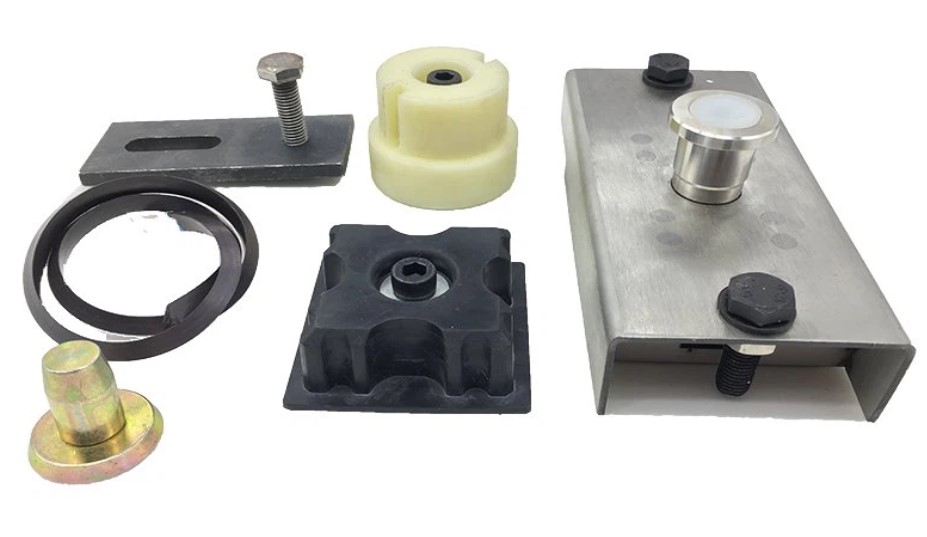

Magnetic Force with the Handle

For the previous magnetic box system with a button ON/OFF, an extra steel lever will be used to remove, the magnet in the productive procession. While It can be fitted with adapters and accessories easily with two M16x1.5 threaded holes. Alternative threading positions and sizes are possible on request.

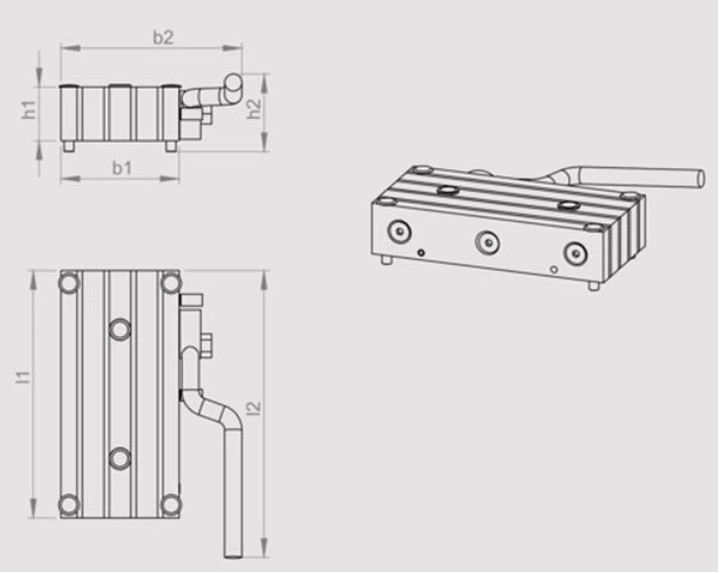

Parameters of MagFly Magnet Compact Solution for Positioning Magnetic Force

|

Part No. |

Magnetic force [Kg] |

Weight [kg] |

l1 [mm] |

l2 [mm] |

b1 [mm] |

b2 [mm] |

h1 [mm] |

h [mm] |

|

LSC- 1000 |

1000 |

5,0 |

230 |

270 |

60 |

115 |

50 |

65 |

|

LSC- 1600 |

1600 |

7,5 |

230 |

270 |

85 |

140 |

50 |

65 |

|

LSC- 2000 |

2000 |

10,0 |

230 |

270 |

110 |

165 |

50 |

65 |

|

LSC- 2500 |

2500 |

12,5 |

230 |

270 |

135 |

190 |

50 |

65 |

|

LSC- 3000 |

3000 |

15,0 |

230 |

270 |

160 |

215 |

50 |

65 |

Application of Magnetic Shuttering Solutions for Precast Concrete Formworks

What Should Pay Attention to When Using the Shuttering Magnet?

①The tightening nut cannot be lowered, otherwise the magnetic box body is pushed up too much and the contact surface is too large, resulting in insufficient adsorption and side displacement.

②The surface of the steel mold on which the magnetic box is placed should be flat, and it should be cleaned before each use. There should be no concrete residue or other particulate matter, so as not to affect the incompatibility of the magnetic core and the mold table and affect the fixing strength.

③ Before and after the use of the magnetic box, the contact surface of the magnetic core should be cleaned, and no concrete and iron filings can stick to it, which will affect the adsorption force.

④ Always clean the concrete stuck on the body and apply oil, and regularly add oil to the guide rod position to ensure the smooth opening and closing of the magnetic core.

⑤ It is forbidden to hit the body with a hard object such as a hammer, or fall freely to the steel surface from a high place, otherwise the strong adsorption force of the magnetic core itself may damage the box body and affect the use, and even cause the magnetic core to dislocate and damage the magnetic box.

Others Hot Sale:

Technical Support for Shuttering Magnet For Precast Concrete

LSC has a group of experienced technical research and development team and professional production equipment including laser cutting machines, CNC electro-hydraulic bending machines, gantry milling machines, CNC lathes, imported flexible welding platforms, etc., to ensure advanced product design, sophisticated production, excellent quality, and provide professional customized services according to customer needs to meet the different needs of customers.

Tags :