-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

The rebar-tying wire is specially designed for various rebar-tying tools on the market. It has excellent toughness and elasticity, will not crack even after multiple bends, and is easy to shape, ensuring that you have enough use over some time. This rebar tying wire is made of high-quality low-carbon steel materials and undergoes a precise process, including wire drawing, pickling, high-temperature annealing, hot-dip galvanizing, and cooling, to ensure the uniformity and thickness of the galvanized layer, improving corrosion resistance, and extend the service life of the product. Its good flexibility meets various tying needs, making the rebar tying wire a powerful assistant in your construction; the spool has been reinforced to improve durability and reduce the risk of wire breakage. The high-strength shaft design ensures its stability and durability in long-term use.

Item No :

Tie Wire Rebar Tie Wire for Rebar Tying MachineOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7daysWhat is Rebar Tie wire?

Rebar tying wire is a high-performance material designed specifically for the construction industry. The low-carbon steel material used ensures the tying wire's high strength and good ductility, allowing it to remain stable even when subjected to heavy loads. Rebar tying wire is compatible with many brands of rebar tying machines on the market, ensuring efficient and smooth operation, whether manual or automatic. After special processing, rebar tying wire is not prone to wire jamming during use, reducing delays and failures in construction. Each batch of rebar tying wire undergoes strict quality inspections before leaving the factory to ensure that it meets industry standards and customer requirements.We also sell strapping guns of the same quality as Max, and the price is more than half cheaper than Max!! Contact us for more information!

Advantages of Rebar tie Wire:

1. Double the speed, save costs, shorter tying height, save time and tying wire length.

2. Faster, stronger and easier to operate.

3. Helps reduce costs and shorten construction time.

4. The wire height is reduced by 50%.

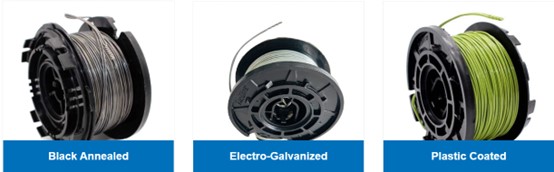

Surface Treatment of Rebar Tie Wire:

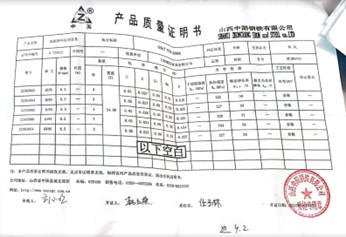

Test report of Rebar tie Wire:

Please rest assured to buy our products. Each batch of our raw materials comes from well-known large factories. Our products absolutely meet the quality standards of export products. We can also issue relevant test reports according to customer needs.

Package of Rebar Tie Wire:

We can ensure that every product we sell meets the customer's production standards, and we will carefully package each product before sending it to the customer.

Why choose Us?

Short production time: Our company has established a solid partnership with more than 100 factories

2. Reasonable price and high quality: Quality and price are our focus because we know what you care about most.

3. Satisfactory after-sales service: Mid-term production report and photos will be sent to you and the completion date will be confirmed again. We will establish close contact with you. If you have any questions, you will get a reply at the first time.

4. Free samples: Free samples are available at any time.

You can get competitive prices from us because we have a huge manufacturing relationship in China.

FAQ

Q: Are you a factory?

A: Yes, we are a factory, that has more than 15 years of experience in producing Q195 carbon steel wire, tie wire, and tie wire spools. We produced tie wire spool fit for MAX, MAKITA, TJEP, BN, RAPID, and Other Chinese Brands rebar tier tools.

Q: Can you provide free samples for testing?

A: Yeah, of course. Welcome to test and compare our wire spool with MAX's original, we are sure you will be satisfied with it. Our company has provided carbon steel wire to MAX before.

Q: How should I pay for the freight of the sample?

A: Sample express freight is free. If you think the sample is free and you should pay for express freight, we will reduce double sample express freight when you place a large order.

Q: What is your delivery time?

A: Our daily output is 20,000 spools/working day, normally lead time: is 7-15 days or negotiation based on your order quantity.

Q: Can you send us samples?

A: We are glad to send you samples to test the quality and market.

Q: Regarding your products, can you do OEM?

A: Yes, OEM service is available.

Q: Do you also provide spare parts for pneumatic tools?

A: Once we confirm the model you want to order, we will send you the diagram for checking and recommend you some easily damaged parts.

Q: For the product, can you spray paint in other colors?

A: Yes, the color can be customized.

Q: Can I mix different models in one container?

A: Yes, different models can be mixed in one container, but the quantity of each model shall not be less than the MOQ.

Q: How is the quality control in your factory?

A: We attach great importance to quality control from the beginning, and each product is tested piece by piece before delivery.

Q: Do you have quality certification?

A: Yes, we have CE, SGS, ISO, etc.

Tags :