-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Pull strength Welding shuttering Magnet with Fixing sticks,Adaptable Side Shuttering Magnet For Wooden and Steel Sides,Neodymium Embeded Precast Concrete Magnetic Component, NdFeB PC Magnet, Switchable Button Shuttering Magnets, stainless steel magnet box Slide rail adapter for plywood, Magnetic Block, Formwork Magnet. Corner Square Button Magnet, Magnetic Formwork System, Magform Magnet China supplier Factory

Item No :

Shuttering Magnets with Side RodsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysWhat are Shuttering Magnets With Hanging Rod?

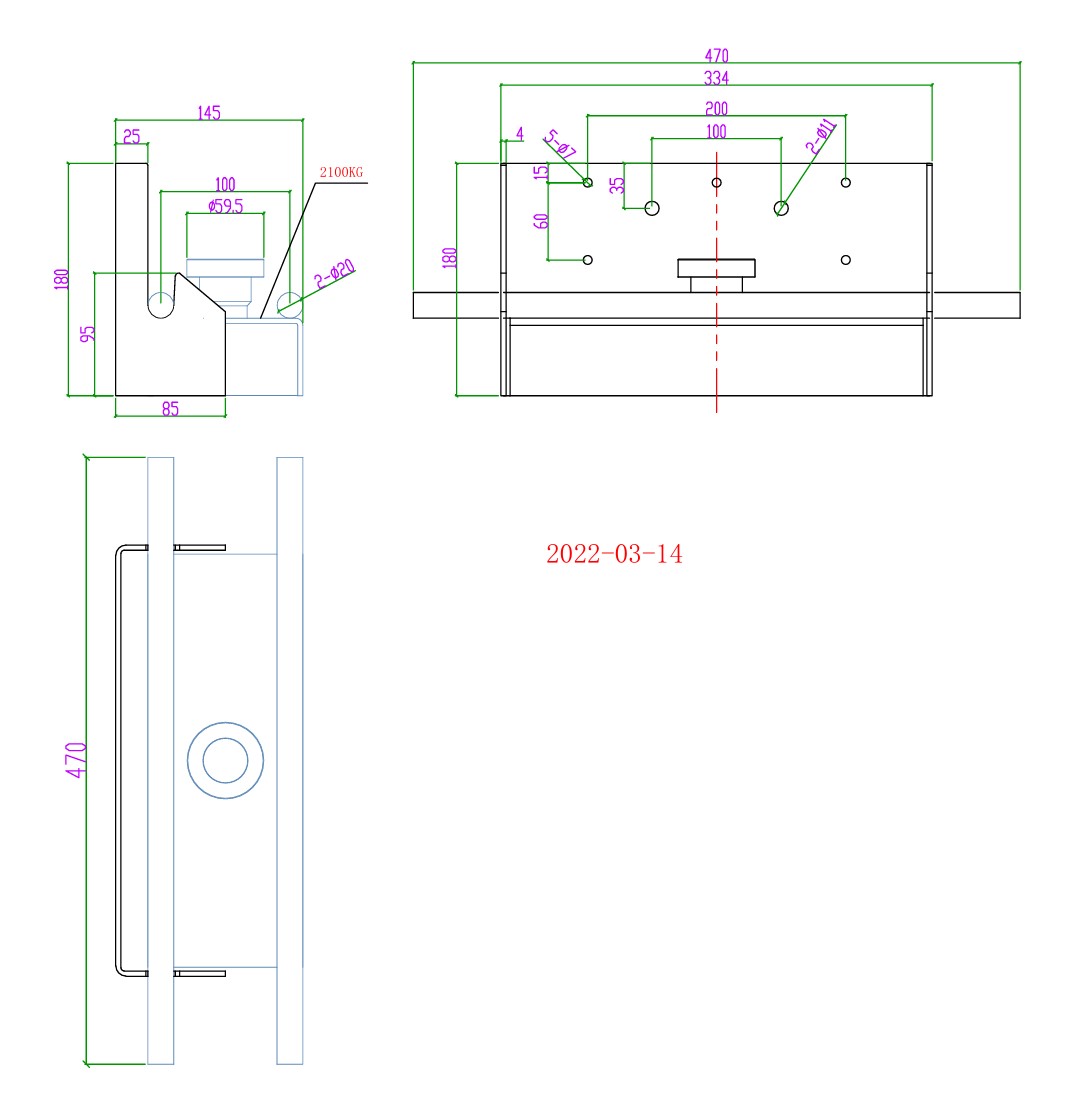

Shuttering Magnets With Hanging Rod is an evoluted type magnetic system on basis of standard switchable push/pull shuttering magnet. The solid welding rod is specially produced to fix customers' formwork side rail in the precast processing. Manually hang the rod onto the groove of form rails and push down the button to active the magnet. Owing to the integrated neodymium magnet systems, it could perform over 2100kg magnetic force, which firmly hold on the steel platform from sliding under concrete pouring and vibrating.

The shorter length of magnet body could extremely reduce the occupation of your table and increase the module efficiency. lt features light weight for easier operating than standard formwork button magnets.

1.Precast Concrete shuttering Magnets are the standard magnetic fixing solution for securing precast frames to steel tables. It is widely used on steel, wooden/plywood frames with or without additional adapters. This button magnet with two side poles can be placed directly into the steel frame without the need for additional adapters.

2.It is constructed with a steel casing and welded steel rods, with a switchable spring-loaded push button integrated with a magnetic system. Benefit from the super neodymium magnet block present, which provides a strong and continuous holding force to the frame, preventing slipping and shifting issues.

Shuttering Magnets With Hanging Rod designed by LSC for customers:

Quality Control of Precast Concrete Shuttering Magnet

LSC has a complete set of quality control system, including complete quality inspection documents, inspection equipment and professional inspection personnel. From the raw material incoming inspection, the production process control and the finished product inspection before leaving the factory are all strictly controlled. It can be taken for granted that the qualified rate of products leaving the factory exceeds 99%.

Technical support for Precast Concrete Shuttering Magnet

LSC has a group of experienced technical research and development team and professional production equipment including laser cutting machines, CNC electro-hydraulic bending machines, gantry milling machines, CNC lathes, imported flexible welding platforms, etc., to ensure advanced product design, sophisticated production, excellent quality, and provide professional customized services according to customer needs to meet the different needs of customers.

Tags :