-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Precasting Concrete Lifting Ring Clutch are specialized lifting devices used to safely handle and transport precast concrete elements. These clutches are designed to work with Erection Anchors embedded in the concrete, ensuring secure attachment and efficient lifting operations.

Item No :

Precasting Concrete Lifting Ring ClutchOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7daysThe Precasting Concrete Lifting Ring Clutch Description:

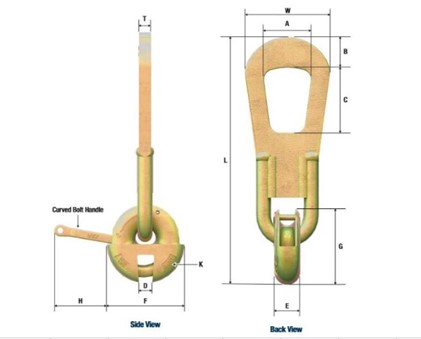

Ring clutches are divided into standard Lifting Clutch and Cable Ring Clutch. It is a component composed of clutch body, bent bolt/handle, and retaining ring. It is very similar to a quick lift ring clutch, but with a longer handle. The installation of the device is fast and simple; Simply rotate the bent bolt/handle to the open position, place the main body into the anchoring groove, and then rotate the bolt/handle to the closed position.

Lifting Clutch Cable Ring Clutch

Specification of Ring Clutch:

| NO. | Load Range | A | B | C | D | E | F | G | H | Ultimate capacity in tension (lbs) |

Weight (lbs ) |

| LSCQL001 | 2T-3T | 2-1/4'' | 1-1/16'' | 2-3/4'' | 1/2'' | 1-1/8'' | 3-1/8'' | 3'' | 2-1/2'' | 30000 | 3.57 |

| LSCQL002 | 4T-6T | 2-5/8'' | 1-1/2'' | 4-1/2'' | 3/4'' | 1-7/16'' | 4-1/8'' | 4-1/8'' | 3'' | 60000 | 8.04 |

| LSCQL003 | 8T-12T | 3'' | 1-15/16'' | 5-3/8'' | 15/16'' | 2'' | 5-5/16'' | 5-5/16'' | 3-3/8'' | 120000 | 20.57 |

| LSCQL004 | 12.5T-22T | 4-7/8'' | 2-5/8'' | 6-3/8'' | 1-3/8'' | 2-7/8'' | 8-1/8'' | 8-1/8'' | 3-7/8'' | 220000 | 59.77 |

Ring Clutch Application and Installation:

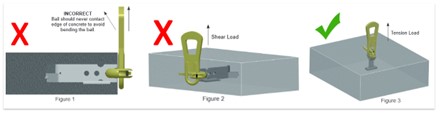

Ring Clutch is used with Fleet Lift Anchor for lifting and handling precast concrete panels. The Ring clutches are matched to the anchors by compatible design as well as by marking the anchor types and load groups. Only matching components will fit together.

When the head of the lifting clutch is inserted into the recess and anchor head, the bolt will lock down the anchor from the head of the lifting clutch. The lifting clutch casting head needs special head treatment to improve mechanical performance.

1. The Ring Clutch is located directly over the head of a Fleet-Lift Anchor.

2. The ring clutch is pushed down onto the anchor head and the curved bolt is rotated through the engagement hole of the anchor and locked into position. The process of engaging the anchor and ring clutch is completed in seconds.

3. To disengage the anchor and ring the clutch, simply pull the curved bolt free of the anchor. This allows the ring clutch to be easily removed from the head of the anchor.

4. Recommends a minimum ¾" cover between the bottom of an anchor and the concrete surface. This minimum recommended concrete cover is to prevent anchor corrosion.

5. The load line should be in line with the center of the bail, lifting from the top of the bail only. Bail should never contact the edge of concrete to avoid bending the bail.

Cape Ring Clutch:

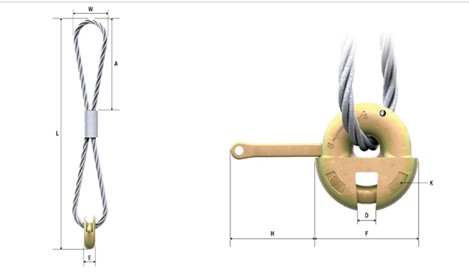

Cape Ring Clutch consists of a clutch body, a curved bolt, and a high-strength bail. the curved bolt is free to move in any direction. The clutch in each load group matches the shape of the recess former and incorporates a locking bolt that engages in the head of the cast-in anchor.

The Cable Ring Clutch is a lifting assembly consisting of a cable with swage, clutch, and curved bolt handle. To correctly use the clutch, slide the curved bolt to the open position, align it with the lifting anchor opening, then slide it to the closed position.

The Cable lifting ring clutch is an efficient, fast method in a connect/disconnect lifting system allowing precast concrete elements to be handled safely, with reliable and repeatable use. The high-quality, engineered ring clutch is dimensionally measured, mechanically load tested and magnetic particle inspected to ensure the manufacturing process meets and/or exceeds minimum design requirements.

Lifting loops with changed wire length as per customer's requirements.

Specification of Cape Ring Clutch:

| Number# | Load Range (T) | L | W | A | D | E | F | H | Ultimate capacity in tension (lbs) | Weight(lbs) |

| LSC001CB | 2-3 | 23-3/4'' | 4-7/8'' | 10-1/2'' | 1/2'' | 1-1/8'' | 3-1/8'' | 2-1/2'' | 30000 | 3.87 |

| LSC002CB | 4-6 | 25-1/2'' | 5-5/8'' | 10-5/8'' | 3/4'' | 1-7/16'' | 4-1/16'' | 3'' | 60000 | 7.38 |

| LSC003CB | 8-12 | 33-1/2'' | 6-3/8'' | 15-1/2'' | 15/16'' | 2'' | 5-15/16'' | 3-3/8'' | 120000 | 22.11 |

| LSC004CN | 12.5-22 | 62'' | 8/7-8'' | 21'' | 1-3/8'' | 2-7/8'' | 8-1/2'' | 3-5/8'' | 220000 | 60.63 |

Cape Ring Clutch Application:

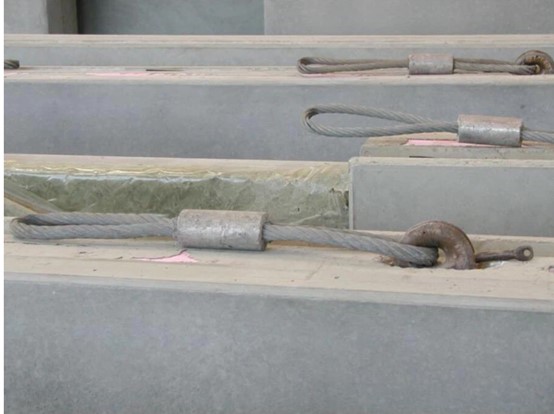

Factory of Precasting Concrete Lifting Ring Clutch:

Test of Precasting Concrete Lifting Ring Clutch:

All production process according to ISO9001 standard, we will make tensile testing within in production process as QCM and make dimension inspection, tensile testing before shipment and issue report for our client.

How to check and maintain the ring clutch and wire rope ring clutch?

1. The ring clutch should be cleaned prior to inspection to ensure any cracks or damage can be seen by the inspector

2. Visually inspect the cable for any kinks and bends. Check for broken cables/wires/strand braids, cable compression set, cable corrosion scars, and excessive damaged or frayed wires. If the ring clutch does not meet any of these criteria, it must be taken out of service.

3. Check whether the cable connector is damaged or severely worn. Check the cable coupling for signs of cable slippage. If signs of heating are present, use of the device must be discontinued

4. Visually inspect the clutch body for any splits, cracks, deformation, overheating or damage. If a clutch body does not meet any of these criteria, it must be taken out of service.

Tags :