-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

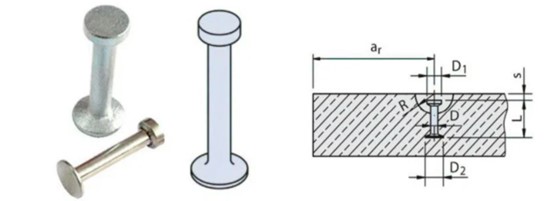

Brief Description of Precast Concrete Lifting Anchors:

Lifting Anchors, Clutches and accessories make lifting concrete components easy, efficient, and safer during transportation, rigging, and lifting of precast concrete elements.

The Lifting Anchors system utilizes a fully engineered approach combining cast-in lifting anchors, recess formers, and custom-fitting lifting clutches. Using the Lifting Anchors system results in fewer failures, saving time and costs due to damage or construction delays.

Lifting Anchor is the most versatile and widely used anchor in the Lifting Anchor range. Available in a wide range of Working Load Limits (WLL), all Lifting Anchor comply with AS 3850.1:2015.

Item No :

Precast Concrete Lifting AnchorsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

10-15days

Brief Description of Precast Concrete Lifting Anchors:

Lifting Anchor is hot forged from Manganese steel. The former head provides spherical seating that the Lifting Eye engages, while a disc-shaped foot is embedded in the concrete. Due to its being a forged part, the Swift Lift Anchor does not depend on welds or thread engagement to develop its safe working load. Forging provides maximum safety with its advantageous material structure. This allows the anchor to easily meet the OSHA requirement of a 3 to 1 factor of safety. Using the Lifting Anchor system results in fewer failures, saving time.

Specification of Lifting Anchor:

|

Code |

Load group |

L |

D |

D1 |

D2 |

S |

R |

Ar |

|

T |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

|

|

LA1.3-120 |

1.3 |

120 |

10 |

19 |

25 |

10 |

30 |

390 |

|

LA1.3-240 |

1.3 |

120 |

10 |

19 |

25 |

10 |

30 |

390 |

|

LA2-190 |

2 |

190 |

14 |

26 |

35 |

11 |

37 |

450 |

|

LA2-280 |

2 |

280 |

14 |

26 |

35 |

11 |

37 |

450 |

|

LA2.5-170 |

2.5 |

170 |

14 |

26 |

35 |

11 |

37 |

540 |

|

LA2.5-280 |

2.5 |

280 |

14 |

26 |

35 |

11 |

37 |

540 |

|

LA4-210 |

4 |

210 |

18 |

36 |

45 |

15 |

47 |

675 |

|

LA4-240 |

4 |

240 |

18 |

36 |

45 |

15 |

47 |

675 |

|

LA4-340 |

4 |

340 |

18 |

36 |

45 |

15 |

47 |

675 |

|

LA4-420 |

4 |

420 |

18 |

36 |

45 |

15 |

47 |

675 |

|

LA5-240 |

5 |

240 |

20 |

36 |

45 |

15 |

47 |

765 |

|

LA5-340 |

5 |

340 |

20 |

36 |

45 |

15 |

47 |

765 |

|

LA5-480 |

5 |

480 |

20 |

36 |

45 |

15 |

47 |

765 |

|

LA7.5-300 |

7.5 |

300 |

24 |

46 |

60 |

15 |

59 |

945 |

|

LA7.5-540 |

7.5 |

540 |

24 |

46 |

60 |

15 |

59 |

945 |

|

LA7.5-680 |

7.5 |

680 |

24 |

46 |

60 |

15 |

59 |

945 |

|

LA10-340 |

10 |

340 |

28 |

46 |

70 |

15 |

59 |

1100 |

|

LA10-680 |

10 |

680 |

28 |

46 |

70 |

15 |

59 |

1100 |

|

LA15-400 |

15 |

400 |

34 |

69 |

98 |

15 |

80 |

1250 |

|

LA20-500 |

20 |

500 |

38 |

69 |

98 |

15 |

80 |

1550 |

|

LA20-1000 |

20 |

1000 |

38 |

69 |

98 |

15 |

80 |

1550 |

|

LA32-700 |

32 |

700 |

50 |

88 |

135 |

23 |

107 |

2150 |

|

LA32-1200 |

32 |

1200 |

50 |

88 |

135 |

23 |

107 |

2150 |

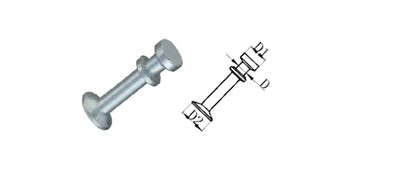

Specification of Double Head Lifting Anchor:

| Code | Rated Load | Sizes (mm) | Popular Length | |||||||

| Tons | D | D1 | D2 | (mm) | ||||||

| DA-1.3 | 1.3 | 10 | 19 | 25 | 50 | 55 | 65 | 85 | 100 | 120 |

| DA-2.5 | 2.5 | 14 | 26 | 35 | 65 | 85 | 110 | 120 | 140 | 170 |

| DA-5.0 | 5.0 | 20 | 36 | 50 | 95 | 120 | 140 | 170 | 180 | 210 |

Specification of Eye Anchor:

| Code | Rated Load | Sizes (mm) | |||

| Tons | D | D1 | L | S | |

| EA-1.3-65 | 1.3 | 10 | 19 | 65 | 8 |

| EA-2.5-90 | 2.5 | 14 | 26 | 90 | 10 |

| EA-5.0-120 | 5.0 | 20 | 36 | 120 | 14 |

| EA-10.0-180 | 10.0 | 28 | 46 | 180 | 20 |

| EA-20.0-250 | 20.0 | 38 | 69 | 250 | 28 |

Safety Factor is 3:1. Other different Lengths and load capacity are available upon request.

Stainless Steel 304 (A2) / 316 (A4) / 20Mn2Aare available upon request

Specification: 1.3T, 2.5T, 4T, 5T, 7.5T, 10T, 15T, 20T, 32T

Surface: Original Color. Zinc Plating. Hot Dip Galvanized

Material Stock System for Precast Concrete Lifting Anchors:

The regular material stock of more than US$ 1.5 million, be ready for the urgent demand.

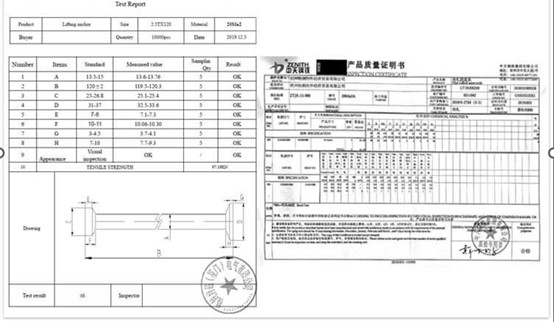

Lifting Anchor Testing Report:

Lifting Foot Anchor Packaging:

The quality of product packaging directly affects the quality of the product. Therefore, we have established a strict packaging management system:

strict responsibility system

inspection system for packaging quality

scientific control statistical method

Packing details, By sea

Wood Carton+ woven bag+ Iron belt

1. Reliable protection of goods and no customer complaints in 7 years.

2. Create conditions for mechanization and automation of loading and unloading.

3. Reduce packaging size, reduce transportation costs.

4. Save packaging costs.

5. To facilitate the inventory of goods.

6. Promote packaging standardization.

7. To reduce storage costs.

8. Moisture-proof

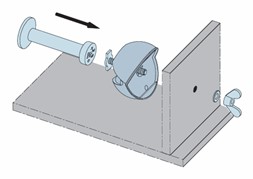

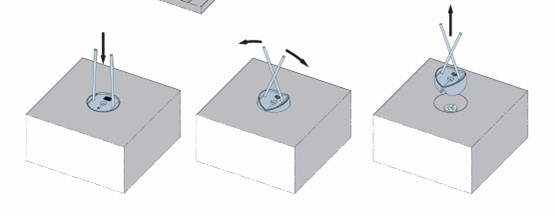

2.The recess former is then fixed onto the formwork using its wing nut on the top of the recess former

3.Finally, the recess former is tightened firmly onto the formwork closing around the anchor head and hence holding it into position

4.Upon removal of the locating plate, the recess former has two holes which can be used as a lever to remove from the cured concrete

Application Picture of Precast Concrete Lifting Anchors:

Why Choose Us?

1.Asian reliable supplier from China, we have served numerous clients all over the world. We have been working with our customers for fifteen years. We have a comprehensive set of services, sales, and after-sales service.

2.We have all the popular design; Small order is accepted and competitive price.

3.Our team will inspect and test goods very carefully when Know the material tread and know the market

4.All inquiries responded within 12 hours Close to the port, providing great advantages to trade

5.What are your payment terms? For other payment terms, we can negotiate about it depend on specific order details.

6.After the product enters the freight forwarding warehouse:

①Our salesman confirms that the bill of lading is correct and informs the customer of the sailing date and arrival date.

②Provide customs clearance information such as invoices, packing data, BL, Form-e and CO, pictures of products entering the warehouse, etc.

③Or provides a one-stop DDP service for customs clearance.

Precast Concrete Lifting Anchors' Relative Project (with):

Tags :