-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Precast concrete lifting clutches are specialized lifting devices used to safely handle and transport precast concrete elements. These clutches are designed to work with lifting anchors embedded in the concrete, ensuring secure attachment and efficient lifting operations.

Item No :

Precast Concrete Lifting ClutchesOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7daysThe Precast concrete Lifting Clutch Description:

The lifting clutch is also known as the Dog Bone lifting clutch. It consists of a protruding lever arm surrounding the main body and a high-strength lifting ring. The main body has a "T" - shaped groove that engages with the head of the Dog Bone lifting anchor. The combined rotational ability of the main body and the rail allows the prefabricated panel to be lifted, rotated, tilted, and/or rotated under load.

The T-bar lifting device consists of a flat release buckle and a clutch head. The lifting body has a locking bolt that allows for quick connection or release of the lifting ring to the Swift Lift anchor, even when wearing work gloves. The design of the universal lifting ring allows the ring to rotate freely by 180 °, while the entire ring can rotate in a 360 ° arc. It supports free movement in any direction.

The standard lifting clutch can be used with various anchor pins. The ring clutch system is the standard lifting clutch that opens all anchors in the anchor system. Our lifting ear load capacity varies from 1.3T to 45T as needed.

|

|

|

| Product Name | Lifting Clutch |

| Material | Steel |

| Package | Nylon bags then in wooden pallet |

| For use with | Lifting anchors, rubber recess former |

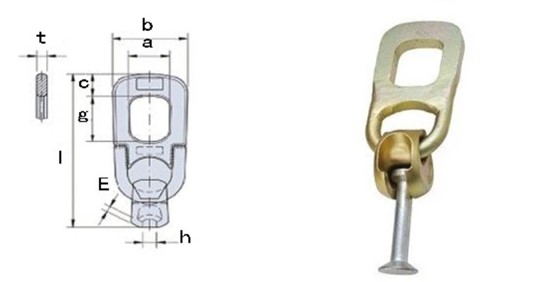

Lifting Clutch Dimension and Specification:

| Code | Load Group(T) | a | b | c | g | h | t | l | m |

| (mm) | |||||||||

| LSC1301-1.3 | 1.3 | 47 | 75 | 20 | 71 | 11 | 12 | 188 | 7 |

| LSC1301-2.5 | 2.5 | 59 | 91 | 25 | 86 | 16 | 14 | 230 | 8.5 |

| LSC1301-5.0 | 5 | 70 | 118 | 37 | 88 | 21 | 16 | 283 | 10 |

| LSC1301-10 | 10 | 88 | 160 | 50 | 115 | 30 | 25 | 401 | 14 |

| LSC1301-20 | 20 | 106 | 180 | 75 | 135 | 41 | 30 | 506 | 21 |

| LSC1301-32 | 32 | 172 | 272 | 100 | 189 | 52 | 40 | 680 | 28.5 |

| LSC1301-45 | 45 | 179 | 349 | 100 | 192 | 52 | 40 | 676 | 28.5 |

NOTE:

1. Surface treatment: electro galvanizing, hot-dip galvanizing

2. The fracture strength is about 5 times the ultimate working load. The safety factor is 5:1.

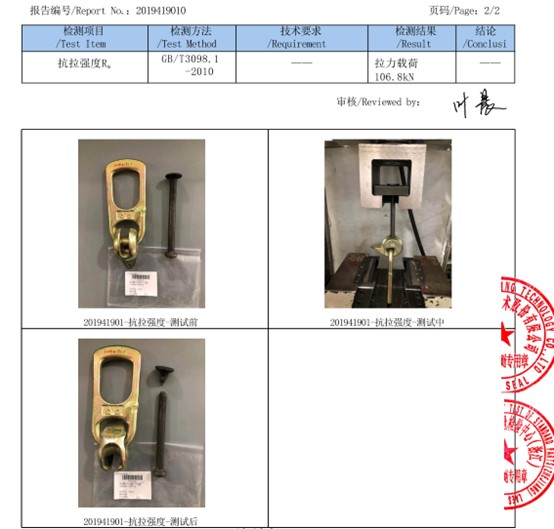

Tensile Testing of Precast concrete lifting clutches:

All production process according to ISO9001 standard, we will make tensile testing within in production process as QCM and make dimension inspection, tensile testing before shipment and issue EATHU's report for our client.

Test Report of Precast concrete lifting clutches:

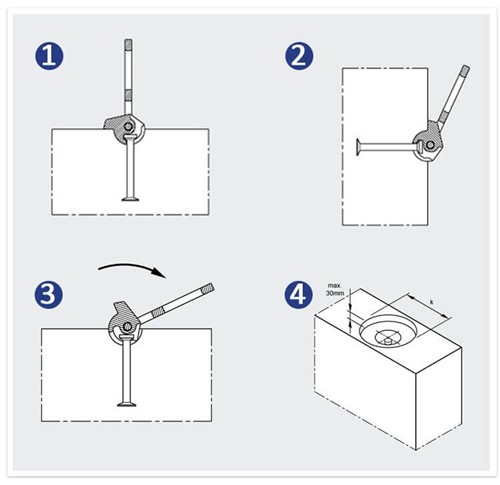

How to Use the Precast Lifting Clutch and Lifting Anchor to Lift the Panel?

①Lifting clutch for precast concrete is attached to the lifting anchor by lowering the clutch slot over the anchor; and then rotating the clutch tab until it rests on the concrete surface.

②The load is raised, anchor takes the full of tension.

As the panel rotates to the vertical position, the clutch comes in contact with the concrete surface; this transfers the lifting force into the concrete; the anchor prevents the clutch from slipping out of the void

④Lifting away from the tab is also safe provided the tab does not rise more than 30° from the concrete surface.

Application of Lifting Clutch:

Lifting clutch are made for primary application of lifting precast concrete components.

Packaging of Precast Concrete Lifting Clutches:

1. Pack with a strong Woven bag

2. Strong Wooden Crate for the sea packing

Why choose us?

1.More than 15 years’ experience in manufacturing and trading of precast concrete systems.

2.Comply with strict technical requirements and meet the market's demand for human safety. (Precast concrete elements may be lifted several times after pouring and during storage and installation - by using this system, designers and workers managers can ensure that each lift is done safely and quickly. Without using a designed and coordinated system , may result in material breakage at some point during production/delivery.

3. LSC's products are enhanced through factory quality control inspections during the production process. Each order can be tension tested if necessary.

4.OEM/ODM capability: LSCE has more than 10 years of experience in OEM/ODM products, more than 150 cooperative factories, we can provide you with competitive prices and stable quality. Excellent quality at a competitive price.

Tags :