-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

MagFly is a high-strength magnetic formwork fixing device designed for formwork support of cast-in-place concrete structures. It uses the strong magnetic attraction of neodymium magnets (NdFeB) to quickly fix steel formwork, aluminum formwork or composite formwork, replacing traditional mechanical fixing methods and significantly improving construction efficiency and quality.

Magfly AP type holding magnets are greatly helpful for fixing the side-forms in place, horizontally as well as vertically. The side forms can be directly screwed or nailed against the plywood. As the material of housing is a casting Aluminum, this magnetic system could offer super power magnetic adhesive force under extreme light weight.

Once need to use it, just press the magnet and it will be activated and attached to the mold table. It can be conveniently released and removed into other position with the above nailed handle. No hammer or lever bar tool required to finish this process.

Item No :

MagFly Shuttering MagnetsOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10daysMagFly Shuttering Magnets

In cast-in-place concrete construction, formwork fixing has always faced challenges such as low efficiency, poor precision, and high labor costs. Traditional wire binding or screw fixing methods are not only time-consuming and labor-intensive, but also prone to problems such as leakage and mold expansion. The birth of MagFly Shuttering Magnets (magnetic formwork fixing system) has brought an efficiency revolution to the construction industry!

MagFly Shuttering magnets featuring a foot/spring system for positioning and detaching. lots adhesive force-to-mass ratio is unique, as is the unique foot/spring system that allows the magnet to glide effortlessly over the formwork table. Firm pressure from above on the magnet activates it, and its magnetic force causes it to adhere to the formwork table. With the integrated lever, the MagFly Shuttering magnets can be easily and quickly released and realigned.

Features of MagFly Shuttering Magnets

1. Powerful holding force over 2000KG, due to the integrated rare earth magnetic block system.

2. Durable and anti-rusty casting Aluminum housing, with extreme light weight under 5.35KG

3. Special four feet with spring could be supportive to create a time gap between magnets placed and moving to right position.

4. Easy operating and releasing, no extra lever tool or hammer required to de-active and remove.

Specification of MagFly Shuttering Magnets

|

||||||||

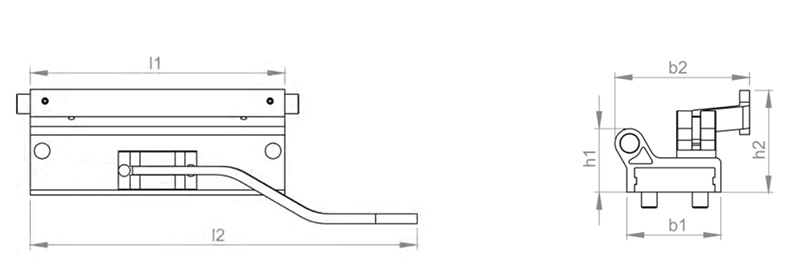

| Number | L1(mm) | L2(mm) | b1(mm) | b2(mm) | h1(mm) | h2(mm) | N.W(kg) | Force(N) |

| LSC-MFSM Right Level | 260 | 407 | 96 | 124 | 65 | 96 | 5.35 | 22000 |

| LSC-MFSM Left Level | 260 | 407 | 96 | 124 | 65 | 96 | 5.35 | 22000 |

| LSC-MFSM 90° Level | 260 | 290 | 96 | 207 | 65 | 85 | 5.35 | 22000 |

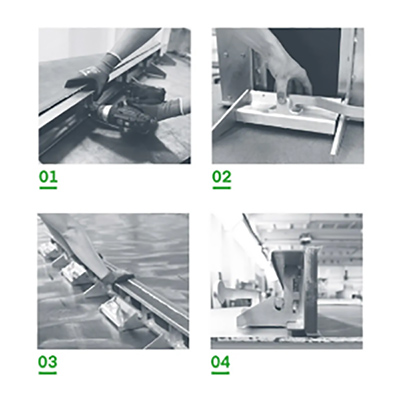

1、Place the formwork facing in front of the MultiForm shuttering system and fix it with screws.

2、MagFly magnets are used in MultiForm

3、Move and place the formwork on the formwork table

4、Fixing the magnets after positioning

Factory of MagFly Shuttering Magnets

The company has a group of experienced technical R&D personnel and professional production equipment including laser cutting machines, CNC electro-hydraulic bending machines, gantry milling machines, CNC lathes, imported flexible welding platforms, and other professional production equipment to ensure advanced product design, excellent production, and excellent quality. LSC specializes in the production of magnetic boxes and can provide professional customized services according to customer needs to meet the different needs of customers.

Application images of MagFly Shuttering Magnets:

Why Choose Us

(1) More than 15 years of experience in manufacturing and trading precast concrete systems.

(2) Comply with strict technical requirements and meet the market's demand for human safety. (Precast concrete elements may be lifted several times after pouring and during storage and installation - by using this system, designers and workers managers can ensure that each lift is done safely and quickly. Without a designed and coordinated system, may result in material breakage at some point during production/delivery.

(3)LSC's products are enhanced through factory quality control inspections during production. Each order can be tension tested if necessary.

(4)OEM/ODM capability: LSC has more than 10 years of experience in OEM/ODM products, and more than 150 cooperative factories, we can provide you with competitive prices and stable quality.

FAQ

Q: Will magnets affect the quality of concrete?

A: Not at all! MagFly adopts a sealed design, and the magnetic lines of force only act on the formwork, without interfering with the concrete reinforcement.

Q: How to recycle the magnets?

A: A special crowbar is provided, which can be disassembled in 3 seconds, and the magnets can be reused.

Q: Can it be applied to curved formwork?

A: The curved magnet base can be customized to perfectly fit the formwork with a curvature radius of ≥50cm.

Tags :