-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

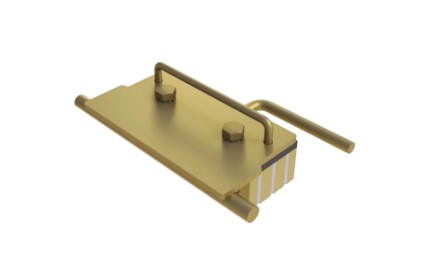

MagFlex Shuttering Magnets with Adapters are a magnetic holding technology used in the precast concrete industry. They are an essential component of precast concrete molds and are primarily used to hold the side molds in place during concrete pouring to prevent cement from flowing out. They provide a fast, secure and flexible way to hold and position the side molds of precast concrete panels through a combination of magnetic force and adapters. This technology is becoming increasingly popular in precast concrete panel forming operations due to its reliability, speed, flexibility and convenience.

Item No :

MagFlex Shuttering Magnets with AdaptersOrder(MOQ) :

1Product Origin :

ChinaLead Time :

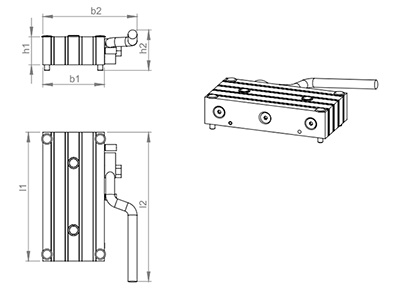

7-10daysMagFlex Shuttering Magnets usually consist of a switchable NdFeB magnet unit, a housing with a magnetic block, and fixing screws. The NdFeB magnet and the steel plate form a magnetic circuit with strong attraction for fixing wooden or steel molds. There is a control button on the top of the precast concrete magnet. When the button is pressed, the magnet firmly fixes the mold on the steel plate through the magnetic circuit. When the button is turned off, the position of the magnet can be easily changed. The two universal threaded holes on the top of the magnet can be equipped with a variety of adapters to meet different usage needs.

Adapters are used to tightly connect the magnetic system with the mold side mold to enhance shear resistance, especially during concrete pouring and vibration. The design of the adapter can be customized according to the shape and height of different molds to ensure synchronization between the magnet and the precast side mold, thereby greatly enhancing the shear force from movement and sliding. Before installing the magnetic box magnet, install the adapter on it and connect it to the mold side rail, which can be welded or nailed into the steel or wooden mold.

Overall, the MagFlex Shuttering Magnets with Adapters deliver exceptional versatility, strength, and adaptability, making them an indispensable tool for any construction project that requires flexible form systems.

Features:

Extremely light weight - easily moved by hand. (No crane delays)

Substantial savings in setup, transition time and material costs

Great value for money - economical cost = fast return on investment

Mag-Fly" strong magnets easily snap into place for fast, precise framing

Track height can be increased using plywood or metal panels

Custom sizes available to meet customer requirements

| Number | Magnetic force (kg) | Weight(kg) | l1(mm) | l2(mm) | b1(mm) | b2(mm) | h2(mm) | h(mm) |

| LSCSH-1000 | 1000 | 5 | 230 | 270 | 60 | 115 | 50 | 65 |

| LSCSH-1600 | 1600 | 7.5 | 230 | 270 | 85 | 140 | 50 | 65 |

| LSCSH-2000 | 2000 | 10 | 230 | 270 | 110 | 165 | 50 | 65 |

| LSCSH-2500 | 2500 | 12.5 | 230 | 270 | 135 | 190 | 50 | 65 |

| LSCSH-3000 | 3000 | 15 | 230 | 270 | 160 | 215 | 50 | 65 |

How to operate?

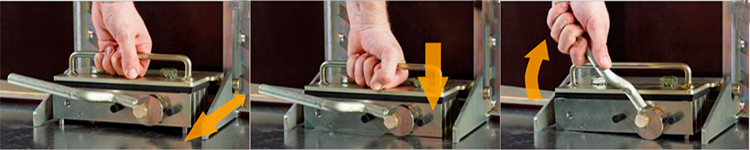

1、To position it, the magnet is pushed along the table with the hand or foot until it reaches the exact position required. Depending on the shuttering system or hold-down device used, this is also possible together with the shuttering.

2、Once the magnets, and the shuttering if applicable, have been precisely adjusted, the magnet is activated using the MagFly® technology by pressing it down with the hand or foot. Its full magnetic force now comes into play.

3、MagFly magnets are removed by pulling the eccentric lever sharply upwards (depending on the model). This releases the magnet and sets it back on its feet.

The advantages of MagFlex Shuttering Magnets with Adapters are:

1、Flexibility and adaptability: The MagFlex system can easily form any curve with a radius of more than 35 cm, which makes it very flexible when dealing with complex shapes and curves.

2、Easy to operate and assemble: Due to its modular design, the MagFlex system can be easily assembled and set up by one person, which greatly reduces labor requirements and operational difficulty.

3、Quick realization of special formwork structures: The MagFlex system allows the rapid realization of special formwork structures, significantly reducing the time for making formwork compared to traditional wooden formwork.

4、Economical: due to speed, reusability and significantly less waste compared to traditional formwork.

5、Precise positioning and secure fixing: Special fixing magnets with MagFly technology ensure precise positioning and secure fixing.

6、The versatility of adapters: Adapters are used to tightly connect the magnetic system to the precast side formwork, increasing the shear resistance, especially during concreting and vibration.

7、Easy to assemble: The adapter can be easily assembled into the box magnet, with two-side threads, such as M12, M16, M18 optional.

8、Various areas of application: MagFlex can be used in the production of solid and sandwich walls, in the manufacture of platform panels, supports and beams, as well as on tilting tables, indexing tables, circulation pallets and wooden surfaces.

|

|

|

|

| MagFly® Universal magnet with guide bold | MagFly® universal magnet with folding adapter | MagFly® universal magnet with hold-down device | MagFly® universal magnet with system adapter |

Application scenarios of MagFlex Shuttering Magnets with Adapters

Our service:

1. Reply to your inquiry in 24 working hours.

2. Experienced staffs answer all your questions in professional and fluent English.

3. Customized design is available. OEM&ODM are welcome.

4. Exclusive, considerate and unique solutions can be provided to our customers by our well-trained and professional engineers and staff.

5. Special discount and protection of sales area provided to our distributor.

Tags :