-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Formwork Precast Magnet Adapter, Shuttering Magnet Fixed Bracket, Magnetic Box Adaptor, Precast Accessories Shuttering Magnet Adapter, Shuttering Magnet Attachment Steel Adapters, precast steel adaptor with magnetic box to fx different formwork, Concrete Formwork Magnet Adaptors & Adapters China Supplier

Item No :

Adaptable Side Shuttering Magnet For Wooden and Steel SidesOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysFeatures of Adaptable Side Shuttering Magnet For Wooden and Steel Sides

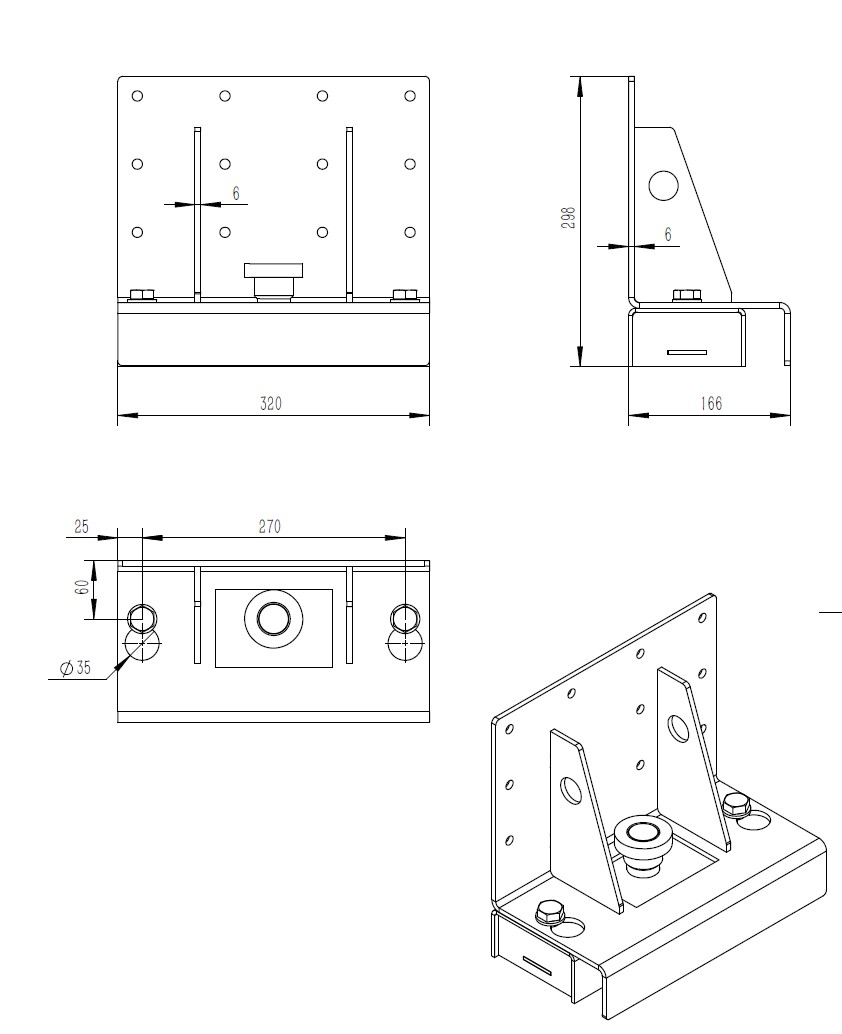

Easy to use, small size, suction power ranging from 450GK to 2100KG, greatly saving mold space Welding thread M12/M16, can be equipped with various adapters according to different purposes Easy to install and manually operate, fast and safe Equipped with various types of adapters, it can be applied to any type of wooden or PVC board we can make different types with customs requirement.

Adaptable Side Shuttering Magnet For Wooden and Steel Sides Project

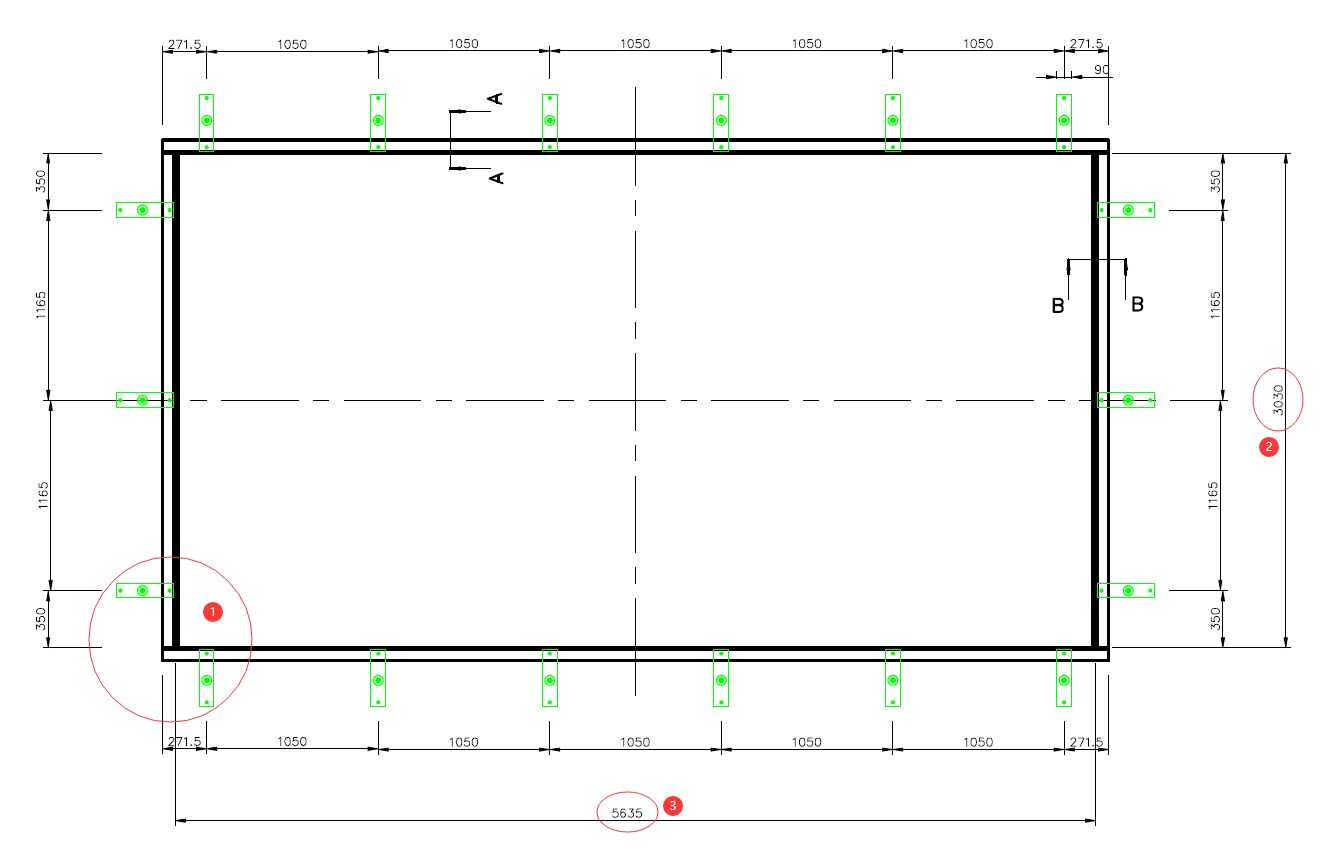

How Many Pieces Shuttering for 3 Meters and 5 Meters Side Formwork?

Features of Adaptable Side Shuttering Magnet For Wooden and Steel Sides

German quality, but price is cheaper at least 50%.

Increase 70% efficiency by using magnetic box and it allows 1 people to perform the task of 3 people.

Easy operation guidance manual.

Speciale’d design to fix framework.

Regular & hot selling models, in stock. Ship within 1 days.

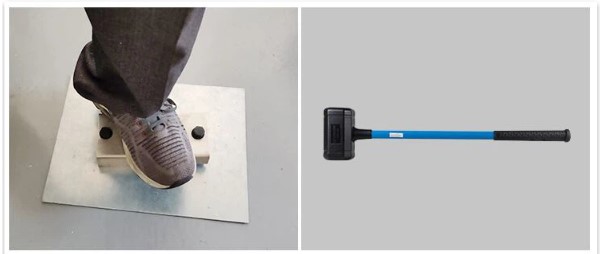

How to Use the Shuttering Magnet?

It is very easy to use this product. Simply move the concrete magnet onto the precast concrete platform (or tray) and press the button.

Open the magnetic field:

Press the button by foot or rubber hammer.

Close the magnetic field:

Pry up the button by the lift lever (also known as the crowbar), the button can easy to be pulled up.

Tip: use 2 pcs tools together when removing more than 1000KG, in case of the lever bending

Shuttering Magnet’s Maintenance And Safety Guidelines

1. Do not crash and use hard tools to knock it.

2. Keep the working surface clean and smooth.

3. Max working and storage temperature should be below 80℃.

4. No corrosive medium around.

5. Clean the working surface after use.

Tags :