-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

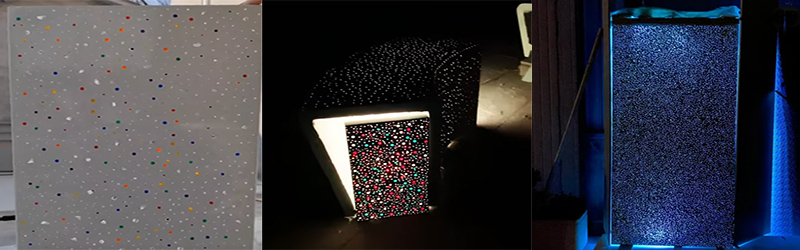

Now the concrete construction industry is becoming more and more diversified, prefabricated wall panels are its further industry innovation, Acrylic Plexiglass Rods are widely used in the prefabricated concrete wall panel industry for decoration, structural support and lighting. Its excellent transparency, durability and plasticity can bring innovative design functions to the wall panels.

Item No :

Acrylic Plexiglass RodsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysAcrylic Plexiglass Rods

"Acrylic" comes from the English word Organic Glass, also known as ACRYLIC or organic glass, which is an important thermoplastic that was developed earlier. Acrylic has good weather resistance, high surface hardness and surface gloss, and good high temperature performance. And its wear resistance is close to that of aluminum, with good stability and corrosion resistance to a variety of chemicals. It is particularly worth mentioning that transparent acrylic has a transmittance comparable to that of glass, but its density is only half of that of glass. In addition, it is not as fragile as glass, and even if it is damaged, it will not form sharp fragments like glass. Therefore, acrylic products are widely used in various fields such as lighting accessories, craft products, household appliances, medical equipment, building materials, and bioengineering.

Acrylic Plexiglass Rods Features:

1. High transparency: The light transmittance of acrylic rods is as high as 92%, the light is soft and the vision is clear, which can be comparable to optical glass.

2. Excellent weather resistance: Acrylic rods have strong adaptability to the natural environment. Even if they are exposed to sunlight, wind and rain for a long time, their performance will not change. They have good anti-aging performance and can be used safely outdoors.

3. Good processing performance: Acrylic rods can be thermoformed or machined. They are easy to cut, drill, bend and bond, and can be processed using various tools and techniques.

4. High toughness and impact resistance: Acrylic rods have high toughness, which is more than 10 times greater than that of ordinary glass. They can withstand greater impact forces and are not easy to break.

5. Lighter weight: The density of acrylic rods is only half that of glass, so they are lighter, easier to transport and install, and reduce the burden on the structure.

6. Good surface gloss: The surface of acrylic rods is smooth, easy to clean and maintain, and can maintain long-term gloss and beauty.

7. Color diversity: In addition to transparent and white, acrylic rods can also be customized in a variety of colors, including black, red, yellow, blue, etc.

8.Cost-effectiveness: Although acrylic rods may be more expensive than traditional materials such as glass in some aspects, it is generally a cost-effective choice considering its excellent performance and long service life.

Specification

| name | acrylic rod | Acrylic tube | Square stick | Square tube | triangle stick | heHexagonal rod | Sphere/ Semi-sphere | Special-shaped materials |

| Outer diameter | 2-300mm | 6-2000mm | 2-300mm 2*2, 3*3 2*3, 4*4 5*5, 6*6 8*8... | 20*20 30*30 39*39 50*50 60*60 100*100 128*128mm |

3-160mm 3*3,4*4, 5*5,8*8 9*9.10*10 15*15.... |

7*80mm | 6-300mm | 2-300mm |

| wall thickness | 0.8-80mm | 2-10mm | ||||||

| length | 2m | 2m | 2m | 2m | 2m | 2m | ||

| Other types | Bubble rod, twisted rod, line rod, light guide rod, trapezoidal rod, semi-circular rod, I-shaped rod, two-color rod, D-shaped rod, frosted rod, special-shaped rod Bubble tube, line tube, inner tooth tube, plum blossom tube, hexagonal tube, octagonal tube, frosted tube, two-color tube, large wall tube, trumpet tube, light guide tube | |||||||

| color | Transparent, milky white, colored, custom colors available upon request. | |||||||

| shape | All solid, hollow, special-shaped products can be customized according to the drawings | |||||||

| Remark | The product types and specifications are not listed one by one, the length can be customized | |||||||

Usage scenarios

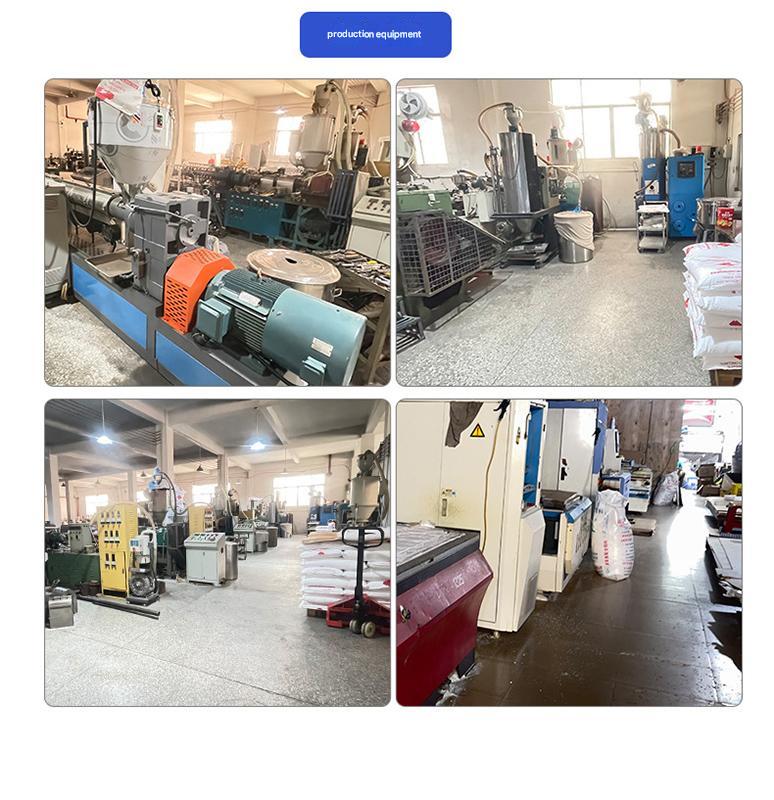

Factory production equipment

Tags :