-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

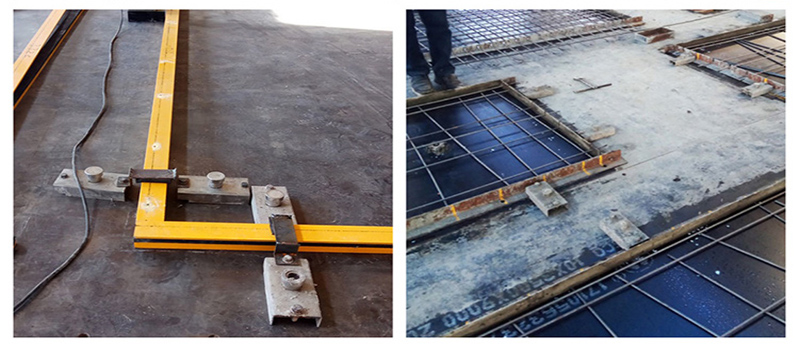

The 4000 lbs (1800 kg) pulling force shuttering magnets, also known as 1800 kg vertical tension precast concrete magnets, are mainly used in the production of precast concrete products. These shuttering magnets can effectively hold the work pieces in place, improve the construction efficiency and ensure the stability of the formwork during the concrete pouring process due to their strong magnetic properties. Shuttering magnets are widely used in a variety of precast concrete building and construction projects, including but not limited to the production of concrete wall panels, columns, beams and other concrete elements.

Item No :

1800KG Precast Concrete Shuttering MagnetOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10days4,000 lbs (1,800 kg) pull-force shuttering magnet

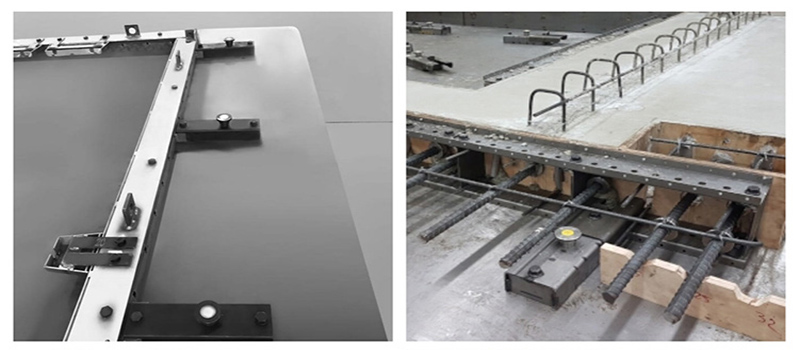

The 4,000 lbs (1,800 kg) pull-force shuttering magnet is designed to stabilize large steel precast concrete platforms. It generates a magnetic force of more than 250 times its own weight, effectively and securely holding the formwork during precast concrete casting. In addition, the precast magnet features an on/off switch that allows for easy activation and deactivation of the magnetic field. Using this magnetic box can reduce labor time and costs while increasing production capacity by up to seven times, all in a single direction.

The 1,800 kg precast magnets are designed for easy installation and operation, ensuring the stability of concrete formwork in a variety of shapes and sizes on steel platforms. They provide excellent durability and can be reused for many years, if used correctly. The magnetic shuttering has been specially designed to meet the needs of the construction industry, featuring rounded edges that enhance compatibility with a wide range of materials. In addition, these magnets cause no wear or scratches on the steel platforms, thus preventing damage and reducing maintenance costs.

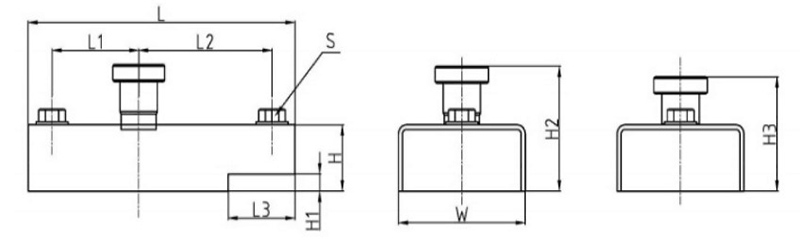

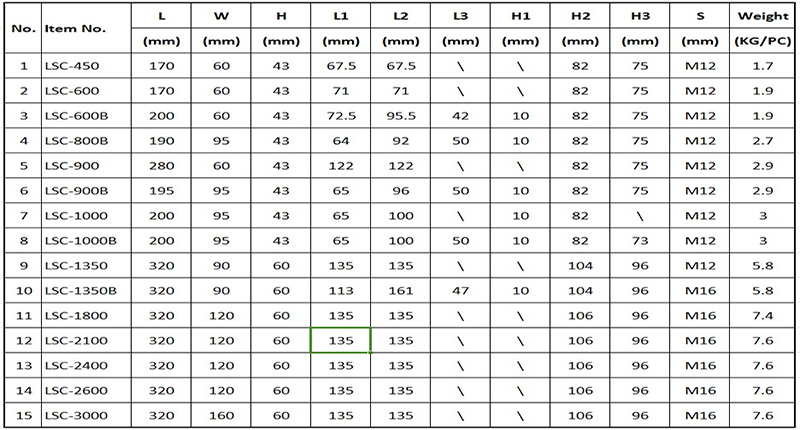

Specification:

Name:Precast Concrete Formwork Magnet/Push-Button Magnet/Precast concrete magnet

Vertical suction: ≥1800kgs

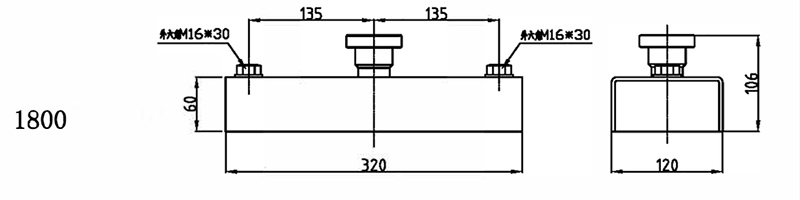

Size: 320x120x60mm/Customizable

Box material: neodymium magnets + steel

Suitable mold height recommended: 120-300mm

The 4000 lbs (1800 kg) pulling force shuttering magnet is a high-performance, reliable and economical precast concrete production aid for a wide range of concrete applications that can improve productivity and quality. The carbon steel housing material effectively protects and protects the magnetic core inside. All bolts and nuts are made of 12.9 grade high-strength alloy material or 304 stainless steel, which can be easily attached to different shapes of external materials to hold the external mold.

In terms of maintenance, care should be taken to keep the suction hole of PRECAST WALL PRODUCTION MAGNET clean and flat, and if it is not used for a long time, it should be oiled to prevent rust. In addition, the use of liquid and water to clean the inside and outside of precast concrete shuttering magnets should be avoided to prevent rust. When in use, Shuttering Magnets for Precast should be kept away from instruments, electrical appliances or other ferrous materials that have an effect on the magnet to prevent separation after connection.

Other Model:

Key Benefits Of Shuttering Magnets:

1. Easy installation and effortless operation. Your workers could choose a fixed position at will and quickly build concrete formwork according to individual architectural design. Significantly save complexity and time and cost on the installation of magnetic formwork (up to 70%).

2. Universal use for mass production of concrete products, and piece different shapes and size of concrete elements of all forms on the same steel table. Excellent applicability, the same prefabricated formwork magnet can be adapted to different concrete formworks. You do not need to have a lot of different forms for different products. The same magnet can be used for different purposes and in different ways.

3. Integrated threaded holes M12 and M16 to adapt formwork and customized adapters, to fix all kinds of side-formwork including wood, steel, and aluminum formworks, eliminating the need for welding, and shuttering magnets do not damage the steel table. Avoid welding or bolting to the formwork table, preserving surface finish and reducing direct damage to the concrete platform in the working.

4.No welding process is required, and the magnetic force of the magnet can be used to fit the template. Avoid welding or bolting to the formwork table, therefore, preserving the surface finish. No need for electric welding, you can save high energy consumption.

5.10-Year-long service life and reusable. Low cost. Short payback period.

Factory of Shuttering Magnet:

Our Factoy has a complete quality control system, including complete quality inspection documents, inspection equipment and professional inspection personnel. It strictly controls the incoming inspection of raw materials, production process control and finished product inspection before leaving the factory to ensure that the pass rate of products is over 99%. Professional customized services can be provided according to customer needs to meet the different needs of customers.

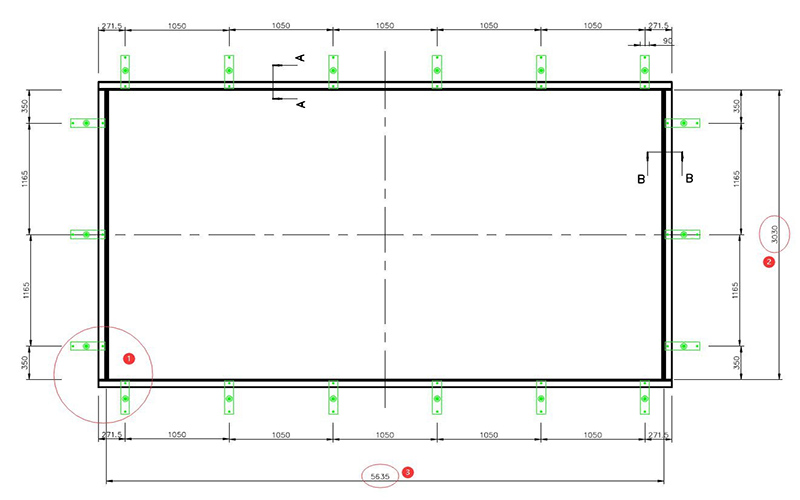

How Many Pieces Shuttering for 3 Meters and 5 Meters Side Formwork?

Application form Shuttering magnets are widely used in various applications in precast concrete production, such as:

- Install side rails and blockouts in formwork.

- Secure molds for wall panels, columns, and other precast products.

- Facilitates rapid changes in formwork configurations to accommodate different designs.

How to Assure the Quality for You?

1. Material

1.1 Material Purchasing

5R Management Material Procurement System. Our purchasing manager has more than 8-year purchasing experience and rich experience in quality control and the advantages of different factories and different products, and different quality levels. We control every material to have stable 2-3 suppliers, who can get much of our orders, and offer stable quality and excellent service. And in our system, we have more than 1000 backup suppliers there, to meet any special and urgent requirement from clients.

1.2 Incoming material quality inspection and control

Besides the neodymium magnets, we also have strict inspections of every incoming material (Dimensions, weight, material level, ductility, permeability, metallographic structure, fatigue test) such as the steel casing, button steel and plastic, the spring, fixing screws, and so on.

In order to improve our inspection strength and ability, we also have a great partnership with 5 3rd party inspection organizations, to do regular and irregular material analysis and inspection.

2. Excellent production equipment for the quality internal control of quality and lead time

Most competitors outsource the post-production processing to a small workshop, but the quality and process control is lacking an internal inspection. Even if they found the problem, it is difficult to improve and solve, and finally, clients are burdened with the loss. This is a serious current situation and problem for Made-in-China production.

Compared with other competitors, we have spared no effort to improve our self-production ratio and equipment-owned ratio since 3 years ago. We imported the automatic laser cutting bed from Europe, to improve precision-oriented and bending machines and so on. It can be said that apart from painting and baking, we have almost mastered all the processes and equipment for the production of shuttering magnets, which leads to better, stricter internal control than our competitors.

3. Pull Strength Testing:

Regarding the detection of suction, we will inspect all orders with less than 10 pcs; if the orders are higher than 10 pcs, our inspection ratio is 10%.

We also use the Advantaged Product Quality Planning (APQP), Potential Failure Mode and Effects Analysis (FMEA), Statistical Process Control (SPC) Production Part Approval Process (PPAP), and Measurement System Analysis (MSA) Error Proofing method to prevent the defects from occurring.

● As mentioned above, the safety stock of our regular products is 2 months. In addition, our safety stock of raw materials and accessories exceeds 3 months.

Tags :