-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Wire Rope Loop Boxes for prefabricated components are special embedded components used in prefabricated buildings. They are mainly used to fix and connect wire ropes. They usually contain one or more wire rope loops for connecting lifting equipment (such as cranes, hooks, etc.) to achieve the lifting, transportation and installation of prefabricated components. It plays an important role in prefabricated buildings, especially when large prefabricated components (such as walls, floor slabs, beams, columns, etc.) need to be lifted, and it can provide safe and reliable connection points.

Item No :

Wire Rope Loop BoxesOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10daysWire Rope Loop Boxes

With the rapid development of prefabricated buildings, prefabricated components have gradually become the mainstream choice in the construction industry with their advantages of high efficiency, environmental protection, and controllable quality. However, the hoisting and installation of prefabricated components have always been a key link in construction. The traditional hoisting method is not only inefficient, but also has safety hazards. How to achieve safe and efficient hoisting has become an urgent problem to be solved in the industry.

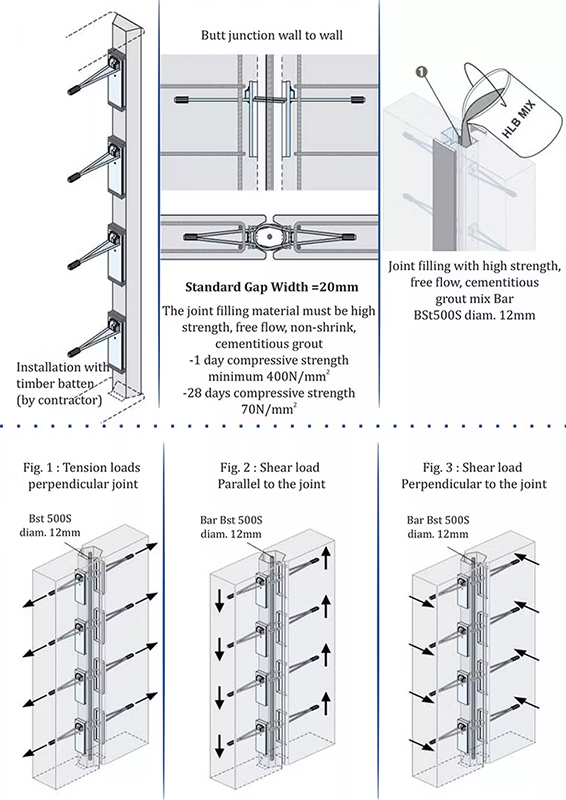

In the precast plant, the flexible cable rings are nailed to the formwork of the precast elements in the form of Single wire rope ring box or Rail Profile Wire Rope Ring Box. At the construction site, the cable rings located on the oppositely placed precast elements are simply folded out and longitudinal rods are installed to prevent cracking in the overlap area. Subsequently, the joints are grouted with high-strength concrete. The design resistance of the load-bearing connection is specified by the regulatory authorities so that multiple precast walls can be connected together to form a shear wall.

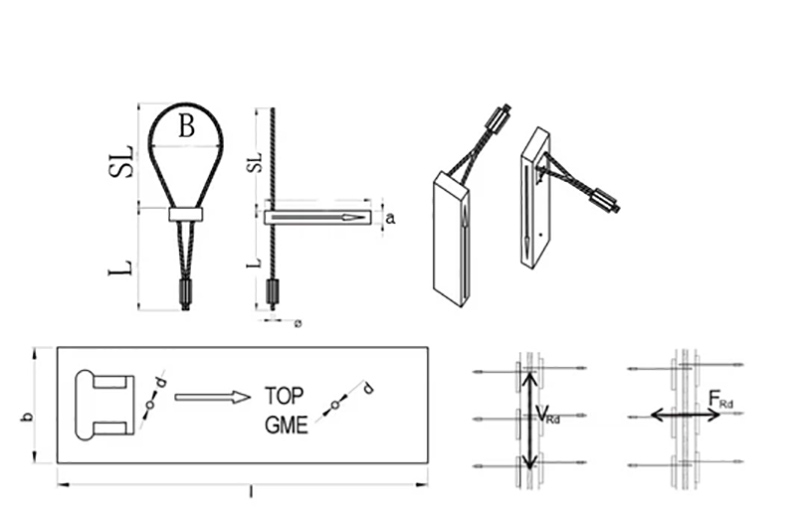

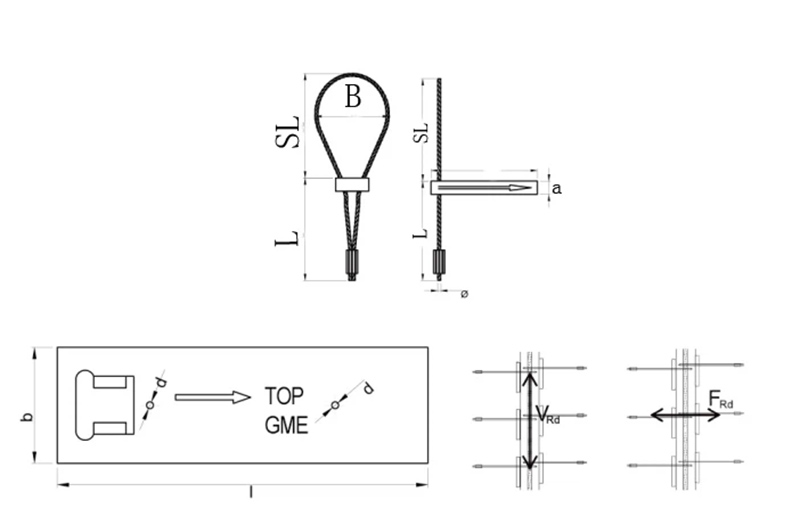

There are two versions of wire loop box, one is single version and one is double version, which includes single and double wire rope loop respectively to ensure the strength of the connection. Its essential material is high-strength galvanized steel wire rope loop box.

Wire Loop Box needs to be fixed on the formwork and the flexible folded wire needs to be pulled out for connection when the site is ready. The load will be transferred from one concrete panel to another through the wire rope loop. The strength galvanized steel wire rope with 6 mm needs to be crimped by using compression sleeve/iron ring to form a loop at one end and transfer the load axially through the other end. The load is transferred from one concrete panel to another through the wire rope loop.

Specification of Wire Rope Loop Boxes

| Item | b (mm) | i(mm) | a(mm) | d(mm) | L(mm) | SL(mm) | Clip Color |

| LSC-S-80 | 80 | 220 | 25 | 3 | 212 | 80 | Black |

| LSC-S-100 | 80 | 220 | 25 | 3 | 212 | 100 | Black |

| LSC-S-120 | 80 | 220 | 25 | 3 | 212 | 120 | Black |

| Item | b (mm) | i(mm) | a(mm) | d(mm) | L(mm) | SL(mm) | Clip Color |

| LSC-D-80 | 50 | 160 | 20 | 3 | 212 | 80 | Black |

| LSC-D-100 | 80 | 160 | 20 | 3 | 212 | 100 | White |

| LSC-D-120 | 80 | 160 | 20 | 3 | 212 | 120 | Blue |

The main advantages and features of the wire loop box, as well as the schematic diagram of its use, are as follows:

• Strong galvanized wire loop

• Pre-punched nail holes for easy fixing on the formwork

• Galvanized steel shell ensures stability during fixing and concrete pouring

• Used for construction connections between precast sections

• Automatic pop-up of the loop ensures time savings; no re-bending is required

• Color-coded plastic clips

• Ideal for butt joints between wall-to-wall and wall-to-column

• Product size is ideal for logistics and storage

Precise positioning: The embedded position of Wire Rope Loop Boxes must be accurate to ensure uniform force during hoisting and avoid tilting or damage of components.

Firm fixation: During the embedding process, it is necessary to ensure that the wire rope ring box for concrete pouring is firmly fixed to the formwork or steel skeleton to prevent displacement during concrete pouring.

Protective measures: Before pouring concrete, be sure to cover the protective cover to prevent concrete slurry from entering the box body and affecting the use of wire rope.

Material quality: Choose high-quality high-strength galvanized wire rope ring box and wire rope to ensure that their bearing capacity and durability meet the requirements.

Construction specifications: Strictly follow the construction specifications to avoid damage or failure of Wire Rope Loop Boxes due to improper operation.

Regular inspection: During the factory production process, regularly check the embedded quality of Wire Rope Loop Boxes to ensure that each batch of components meets the standards.

Production workshop

Application Scenario

High-quality packaging

Tags :