-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Cast-in channels/Anchor channel is a flexible and effective solution to fix various items to precast concrete, It is for easy installation, and adjustable connection. Anchor channels are C-shaped channels with swaged bolts to transfer the load into the concrete. This material is removed easily in long sections and is 100% recyclable. LSC Support Customized, OEM&ODM are welcome, Worldwide delivery.

Item No :

Cast in ChannelsOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10daysWhat are Cast-in Channels?

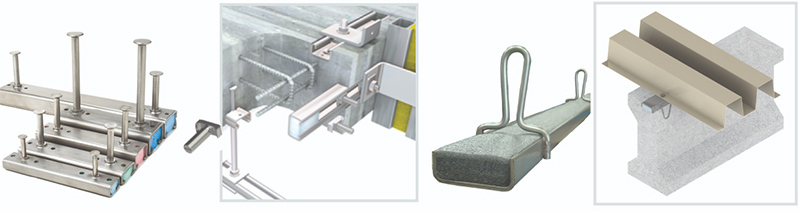

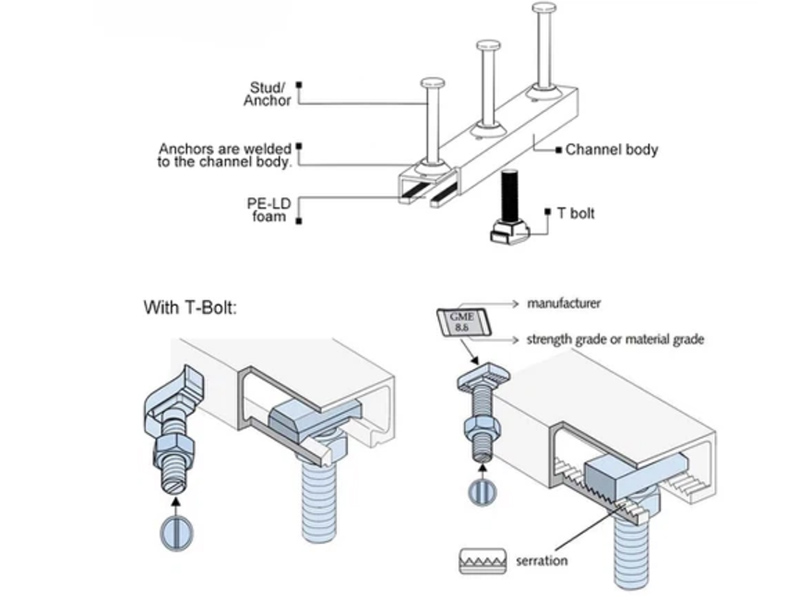

Cast-in channels /anchor channels/Halfen channel is a newly high-end building material, It is for easy installation and adjustable connection. A full foam filler protects against the concrete in the channel.

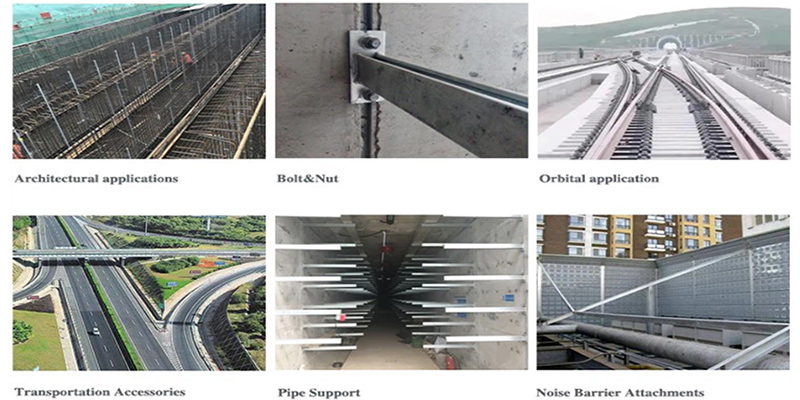

Cast in the channel can be widely used in, tunnels, subways, bridges, airports, nuclear power stations, environmental projects, facades, stadiums, opera houses, and so on.

With advanced Swiss cold riveting technique, to ensure loading capacity is reliable and endurable. We offer high-quality cast-in channels, both hot-rolled & cold-rolled, plus our semi-automatic production of hot-forged T-bolts, a complete range of cast-in channel systems can be provided.

Widely accepted as an ideal way to fix components to precast concrete, our cast-in channels are constructed from cold-formed C-shaped channels with anchor pins swaged on to transfer the load into the concrete. There are 5 profiles and different channel lengths that cover most applications. Our cast-in channels are filled with polythene foam which prevents concrete from getting into the channel during pouring.

Precast-produced cold-rolled and hot-rolled cast-in channels to cast in concrete for various fixing system applications. Cast-in channels are the ideal basis for adjustable fixing and connection and are easy to install. A full foam filling protects the concrete or dirt in the channel. Cast-in channels can be used to create any construction fixing and connections, e.g. facades, precast concrete construction, residential construction, traffic engineering (e.g. tunnels), aor lift constructions, and infrastructure projects such as bridges or crane runway fixings.

Material of Anchor Channel Precast Concrete Hot Rolled Cast in Channel

Our Cast in Channel is made of hot-dip galvanized Q235 carbon steel with at least two anchors on the back. Our material is bought from big Chinese factories such as HBIS, Baosteel, and Magang to guarantee quality, stability, and consistency. Many competitors buy materials from small factories or Recycled materials. Due to the impure composition, the tensile force and pull strength of the product are sharply reduced by at least 15-20%. The quality is not guaranteed, but the material price can be 8-20%.

How to Select Cold Roll Cast in Channel-Cold formed C-groove?

| Size | Pull Force | Standard size(mm) | |||

| KG | Regular Length | ||||

| 28\15 | 120 | 100 | 150 | 300 | 3000 |

| 38\17 | 200 | 100 | 150 | 300 | 3000 |

| 40\25 | 250 | 100 | 150 | 300 | 3000 |

| 49\30 | 400 | 100 | 150 | 300 | 3000 |

| *Other lengths can be customized according to your needs. | |||||

| *Safety factor 3:1. | |||||

| *Stainless steel SS304 and SS316 can also be customized according to the requirements | |||||

| *Surface treatment: primary color, electro-galvanized, hot-plated | |||||

How to Select Hot Rolled Cast in Channel-Hot rolled C-groove?

| Size | Pull force | Standard size(mm) | Anchor | |||

| KG | Regular Length | |||||

| 40\22 | 250 | 100 | 150 | 300 | 3000 | bolt anchor\welded anchor |

| 50\30 | 400 | 100 | 150 | 300 | 3000 | bolt anchor\welded anchor |

| 52\34 | 800 | 100 | 150 | 300 | 3000 | bolt anchor\welded anchor |

| 55\42 | 800 | 100 | 150 | 300 | 3000 | bolt anchor\welded anchor |

| 72\48 | 1000 | 100 | 150 | 300 | 3000 | bolt anchor\welded anchor |

| *Other lengths can be customized according to your needs. | ||||||

| *Safety factor 3:1. | ||||||

| *Stainless steel SS304 and SS316 can also be customized according to the requirements | ||||||

| *Surface treatment: hot-plated | ||||||

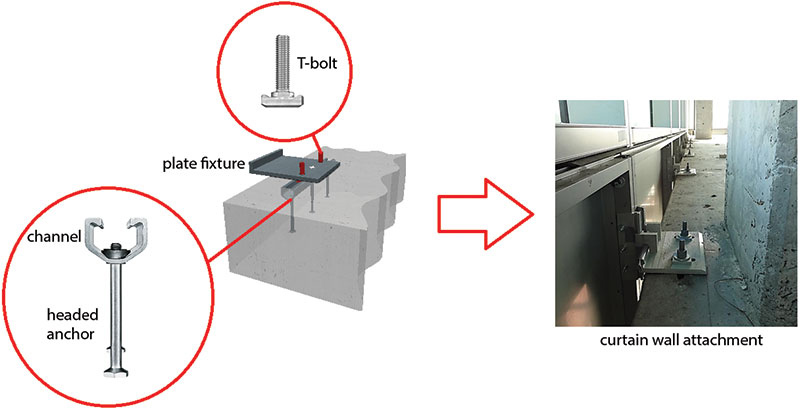

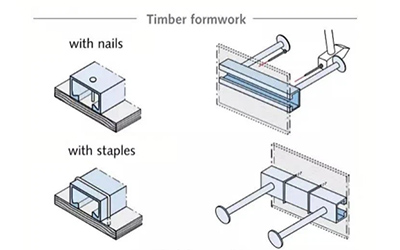

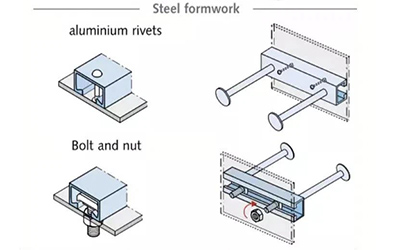

How to use the Cast in Channels?

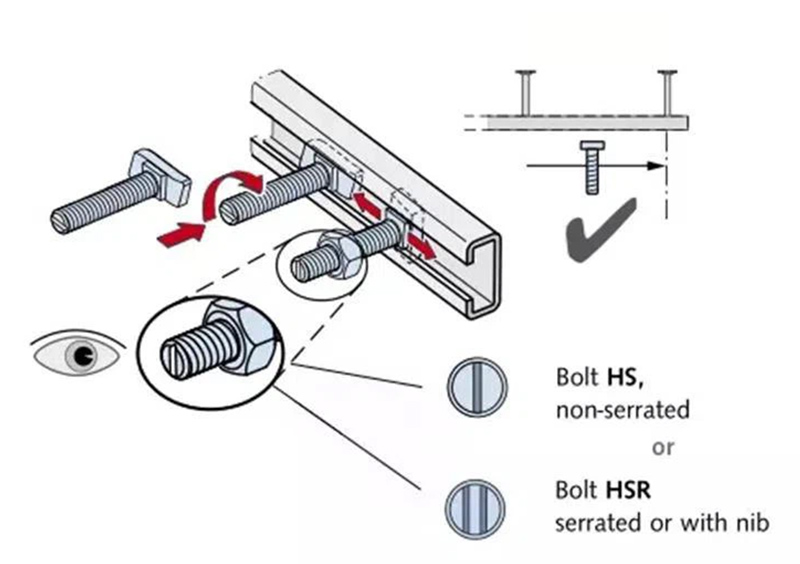

Cast-in channels can be inserted anywhere in the channel slot, turned 90°, and then locked in place by tightening the nut. Do not position bolts at channel ends past the last anchor. On channels with bolt anchors, the anchor locations are visible through the channel slot.

-Fixings

The bolt heads must sit flush on both lips of the anchor channel and be secured by tightening the nut with a torque wrench with the required value.

-Bolts: After installation check that the bolts are properly aligned; the notch or notches in the tip of the shank must be at right angles to the longitudinal axis of the channel.

Suitable for post-tensioned slabs and all construction fixing applications:

• Curtain wall

• Fixing railway tunnel cables

• Stadium seat fixings

• Adjustable fixing

• Fixing in pipes

• Elevator shaft

• Tunnel

Package of Cast in Channels

Good packaging can bring customers a better experience, so our company will be stricter on packaging. The following are our packaging methods, and we can also customize them according to customer needs.

Factory of Cast in Channels

We have a professional factory of a certain scale and professional production equipment. Our products have been exported to various countries around the world for a long time.

Other Hot Sale:

Tags :