-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Thermal insulation Magnetic Liquid Trap

Magnetic Liquid Traps, also named as Magnetic Liquid Filters, are designed for removing Fer rum contamination form liquid or semi-liquid materials with different viscosity, to keep materials purity and protect the equipment. Insulation (I Style) Magnetic Liquid Traps have sandwich, which can be filled with heat insulation materials such as water and oil, to meet the insulation demands of liquid passing through the traps. It is an ideal choice to removing ferrous contamination from chocolate, jams, syrups, jams etc.

Item No :

Magnetic Liquid TrapOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysThermal insulation Magnetic Liquid Trap

Magnetic Liquid Traps are highly efficient and versatile devices designed to capture and remove magnetic impurities from liquid streams. Utilizing powerful magnets, these traps effectively attract and retain ferrous contaminants, ensuring the purity and integrity of the liquid. With their robust construction and user-friendly design, Magnetic Liquid Traps offer reliable performance and easy maintenance. Their compact size and modular configuration make them suitable for various industrial applications, including oil and gas, chemical processing, and water treatment. Upgrade your liquid purification system with Magnetic Liquid Traps, and experience enhanced filtration and increased.

Advantages of Liquid Line Magnetic Ferrous Tube Trap Filter Separator:

●Powerful Rare Earth Neodymium Magnets to remove even the smallest ferrous particles from liquids with a higher viscosity.

●High-Temperature Rare Earth Magnets are standard for temperatures up to 250C.

●Easy clean. Easy spot checks the magnetic bar for contamination with a unique Clean In Place (CIP) design.

●Free maintenance cost.

●Reduce production downtime.

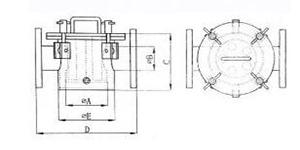

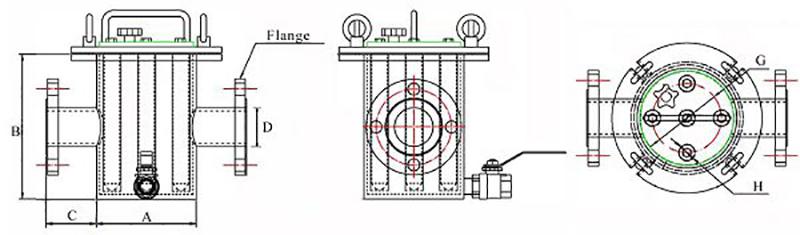

Specification of Liquid Line Magnetic Ferrous Tube Trap Filter Separator:

Liquid line magnets are available in line sizes from 1-1/2" to 8" diameter. Standard 2'', 3'', 4''; Line Diameter, 1/2''; and other sizes available upon request. 2''; Diameter is available for immediate shipment.

|

Item No. |

Flange/Connector |

A |

B |

C |

D |

G |

H |

Bar Quantity |

|

JL-159032 |

DN32 |

Ф159 |

230 |

80 |

Ф39 |

Ф110 |

Ф25 |

5 |

|

JL-159040 |

DN40 |

Ф159 |

230 |

80 |

Ф46 |

Ф110 |

Ф25 |

5 |

|

JL-159050 |

DN50 |

Ф159 |

230 |

80 |

Ф59 |

Ф110 |

Ф25 |

5 |

|

JL-219065 |

DN65 |

Ф219 |

300 |

100 |

Ф78 |

Ф150 |

Ф25 |

7 |

|

JL-219080 |

DN80 |

Ф219 |

300 |

100 |

Ф91 |

Ф150 |

Ф25 |

7 |

|

JL-219100 |

DN100 |

Ф219 |

300 |

100 |

Ф110 |

Ф150 |

Ф25 |

7 |

|

JL-273125 |

DN125 |

Ф273 |

330 |

100 |

Ф135 |

Ф200&Ф100 |

Ф25 |

10 |

|

JL-273150 |

DN150 |

Ф273 |

330 |

100 |

Ф161 |

Ф200&Ф100 |

Ф25 |

10 |

|

JL-325200 |

DN200 |

Ф325 |

360 |

114 |

Ф222 |

Ф250&Ф125 |

Ф25 |

13 |

|

JL-377250 |

DN250 |

Ф377 |

420 |

116 |

Ф276 |

Ф300&Ф160 |

Ф25 |

15 |

|

JL-426300 |

DN300 |

Ф426 |

460 |

118 |

Ф328 |

Ф340&Ф175 |

Ф25 |

17 |

|

JL-480350 |

DN350 |

Ф480 |

510 |

120 |

Ф381 |

Ф380&Ф200 |

Ф25 |

19 |

|

JL-630400 |

DN400 |

Ф630 |

700 |

135 |

Ф426 |

|

Ф25 |

21 |

Cooperative customer case:

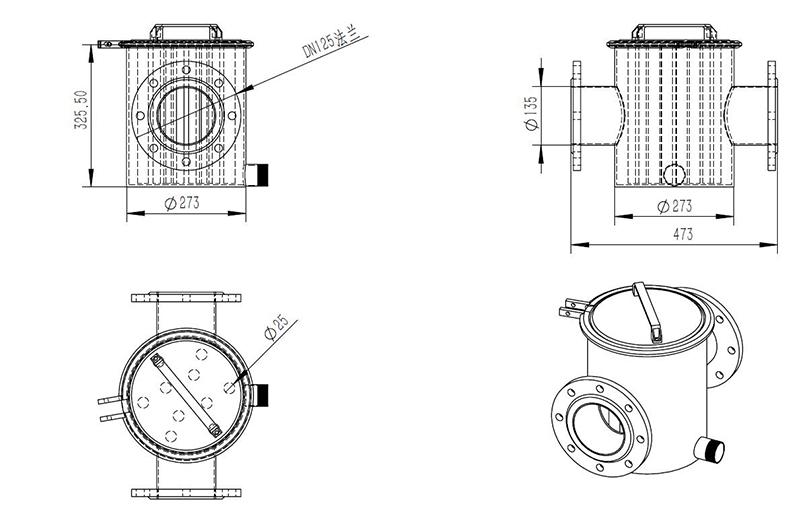

Testing standards and tools for cylindrical iron removers:

The color of the barrel body is uniform, and both the inner and outer walls should be polished to over 400 mesh, with a smoothness of about Ra0.4 and no scratches;

The wall thickness of the barrel is 3-4mm, with a dimensional tolerance of plus or minus 0.05mm;

The welding position must be polished until the weld bead is smooth and there is no blackening of the weld bead

The magnetic rod and cover are firmly connected without shaking.

Use Japanese MT-801 or domestically produced WT301 to test the Gaussian of each magnetic pole point. It is required that at least 1-2 magnetic poles at each magnetic pole point can easily measure the specified Gaussian, with a Gaussian value of plus or minus 300gs. Generally, positive Gaussian is used as the standard.

Please provide the following information before shipment:

A. Use a ruler and vernier caliper to measure the diameter and length of the magnetic rod, with a diameter tolerance of plus or minus 0.05mm and a length tolerance of plus or minus 1mm; Use a ruler and vernier caliper to measure the dimensions of the barrel body, inlet and outlet diameters, flanges, etc., and provide pictures of the measured dimensions for those marked on the drawings.

B. Measure each magnetic pole points with MT-801 or domestic WT301 Gaussian meter, provide pictures or videos (all magnetic pole points of one magnetic rod need to be tested), and require at least 1-2 points of each magnetic pole point to be able to detect the required Gaussian value. The sampling ratio is 10%.

Application pictures of Magnetic Liquid Trap:Magnetic separators are often used in liquid or slurry.

Production Facilities:

Tags :