-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic Liquid Trap

Fluid pipeline iron remover, also known as magnetic fluid iron remover or magnetic fluid filter, is used in fluid, semi-fluid and other viscous fluid materials to remove iron impurities and other ferromagnetic particles, keep the material clean, and at the same time play a role in protecting downstream production equipment.

Item No :

Magnetic Liquid TrapOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysFluid pipeline descaling agents are divided into N Style Magnetic Liquid Trap Magnetic Filters and E Style Magnetic Liquid Traps.

The Fluid pipeline iron remover is an innovative solution designed to efficiently remove iron particles from fluid pipelines. This advanced device utilizes powerful magnetic technology to attract and capture ferrous contaminants present in liquids flowing through the pipeline. With its robust construction and high-performance magnetic system, this iron remover ensures optimal filtration and prevents the risk of equipment damage and product contamination. The seamless integration of this device into fluid pipelines provides a hassle-free solution for industries such as manufacturing, oil and gas, and chemical processing. Experience enhanced productivity, prolonged equipment lifespan, and improved product quality with the Fluid pipeline remover.

Features

1. We designed different styles for the use of different materials.

2. The maximum magnetic strength can reach 13000GS for normal (N Style) and 8000GS for easy cleaning (E Style).

3. Standard working temperature≤80℃, and maximum working temperature can reach 350℃ as required.

4. Easy installation, separation and cleaning through ferrule, bolt plate, flange or uneven head etc.

5. 304 or 316L stainless steel are available for pipeline material.

6. Ideal designed magnetic configuration ensures maximum magnetic effect without liquid flow impediment.

7. As required, specification of customer on pressure or other details is also available.

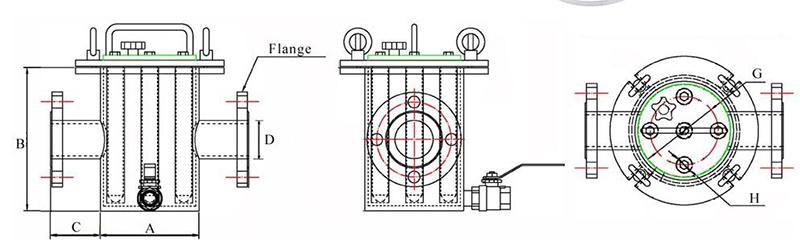

Standard Magnetic Liquid Trap Specification List:

|

Item No. |

Flange/Connector |

A |

B |

C |

D |

G |

H |

Bar Quantity |

|

JL-159032 |

DN32 |

Ф159 |

230 |

80 |

Ф39 |

Ф110 |

Ф25 |

5 |

|

JL-159040 |

DN40 |

Ф159 |

230 |

80 |

Ф46 |

Ф110 |

Ф25 |

5 |

|

JL-159050 |

DN50 |

Ф159 |

230 |

80 |

Ф59 |

Ф110 |

Ф25 |

5 |

|

JL-219065 |

DN65 |

Ф219 |

300 |

100 |

Ф78 |

Ф150 |

Ф25 |

7 |

|

JL-219080 |

DN80 |

Ф219 |

300 |

100 |

Ф91 |

Ф150 |

Ф25 |

7 |

|

JL-219100 |

DN100 |

Ф219 |

300 |

100 |

Ф110 |

Ф150 |

Ф25 |

7 |

|

JL-273125 |

DN125 |

Ф273 |

330 |

100 |

Ф135 |

Ф200&Ф100 |

Ф25 |

10 |

|

JL-273150 |

DN150 |

Ф273 |

330 |

100 |

Ф161 |

Ф200&Ф100 |

Ф25 |

10 |

|

JL-325200 |

DN200 |

Ф325 |

360 |

114 |

Ф222 |

Ф250&Ф125 |

Ф25 |

13 |

|

JL-377250 |

DN250 |

Ф377 |

420 |

116 |

Ф276 |

Ф300&Ф160 |

Ф25 |

15 |

|

JL-426300 |

DN300 |

Ф426 |

460 |

118 |

Ф328 |

Ф340&Ф175 |

Ф25 |

17 |

|

JL-480350 |

DN350 |

Ф480 |

510 |

120 |

Ф381 |

Ф380&Ф200 |

Ф25 |

19 |

|

JL-630400 |

DN400 |

Ф630 |

700 |

135 |

Ф426 |

|

Ф25 |

21 |

Cooperative customer case:

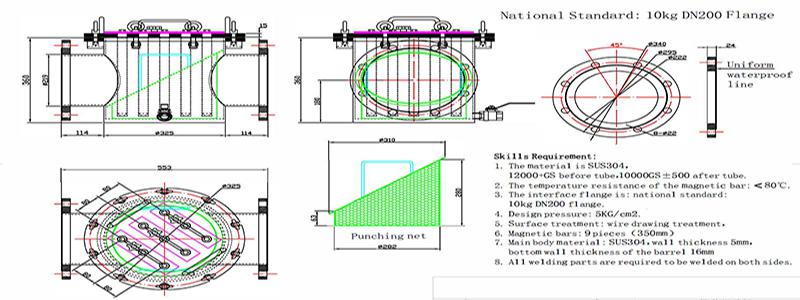

Testing standards and tools for cylindrical iron removers

The color of the barrel body is uniform, and both the inner and outer walls should be polished to over 400 mesh, with a smoothness of about Ra0.4 and no scratches;

The wall thickness of the barrel is 3-4mm, with a dimensional tolerance of plus or minus 0.05mm;

The welding position must be polished until the weld bead is smooth and there is no blackening of the weld bead

The magnetic rod and cover are firmly connected without shaking.

Use Japanese MT-801 or domestically produced WT301 to test the Gaussian of each magnetic pole point. It is required that at least 1-2 magnetic poles at each magnetic pole point can easily measure the specified Gaussian, with a Gaussian value of plus or minus 300gs. Generally, positive Gaussian is used as the standard.

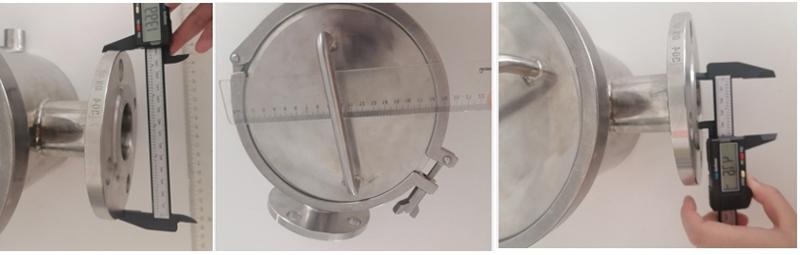

Please provide the following information before shipment

A. Use a ruler and vernier caliper to measure the diameter and length of the magnetic rod, with a diameter tolerance of plus or minus 0.05mm and a length tolerance of plus or minus 1mm; Use a ruler and vernier caliper to measure the dimensions of the barrel body, inlet and outlet diameters, flanges, etc., and provide pictures of the measured dimensions for those marked on the drawings.

B. Measure each magnetic pole points with MT-801 or domestic WT301 Gaussian meter, provide pictures or videos (all magnetic pole points of one magnetic rod need to be tested), and require at least 1-2 points of each magnetic pole point to be able to detect the required Gaussian value. The sampling ratio is 10%.

Installation and use of Magnetic Water Filtration Magnetic Trap:

The liquid magnetic filter interface flange and the slurry output line connected to the slurry from the filter evenly flow, after a period of time to determine the cleaning cycle after the trial.

Clean the cover before the first screw on the clamping screw, remove the casing cover parts, and then out of the magnet, adsorption on the casing of iron impurities can automatically fall off. After cleaning, install the casing into the cylinder, tighten the clamping screw, and then insert the magnet bar cover into the casing, you can continue to use.

Tags :