-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

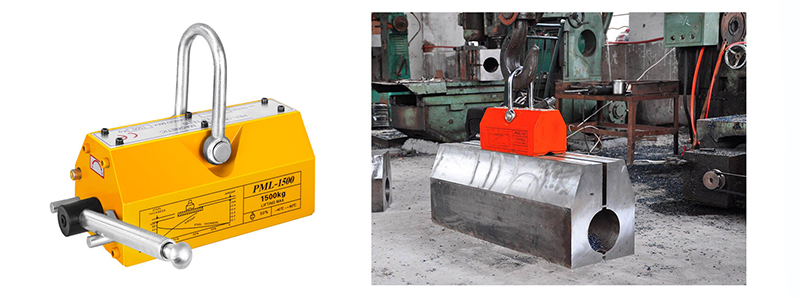

The Steel Permanent Magnetic Lifter is a specialized device designed for the lifting and transportation of heavy metallic objects. It employs permanent magnet technology to generate a robust magnetic field that can securely adsorb and retain metal objects without requiring an external power source or continuous energy supply. This type of magnetic lifter typically comprises a steel enclosure, a set of internal permanent magnets, and a control handle. The internal magnets are made from high-performance materials such as NdFeB, which produce an exceptionally strong magnetic field. The steel enclosure not only protects the magnets but also enhances the overall magnetic effect. Known by various names including permanent magnetic crane, magnetic crane, and lifting magnet, this system is characterized by its compact size, powerful retention capability, absence of power requirements, minimal residual magnetic induction, and high safety factor.

Item No :

Steel Permanent Magnetic LiftsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysSteel Permanent Magnetic Lifts

In various industrial settings, ensuring the safe and efficient handling of materials remains a critical objective. As an advanced lifting solution, Steel Permanent Magnetic Lifts excel in enhancing operational efficiency while maintaining workplace safety. Utilizing state-of-the-art permanent magnet technology, these lifts possess a robust magnetic adhesion capacity. Their steel construction ensures high strength and durability, capable of enduring heavy loads and prolonged usage without deformation or damage. Furthermore, an advanced magnetic control system facilitates precise and effortless control over the magnetic force's engagement and disengagement, thereby guaranteeing the secure handling of materials.

The advantages of Steel Permanent Magnetic Lifts are manifold: Firstly, their operation does not necessitate a power supply or external energy source, offering greater flexibility and simplicity. Secondly, they are adept at managing heavy metallic objects, with a magnetic force that is both durable and dependable. Additionally, their design eliminates the need for ropes, hooks, or other components, significantly reducing the likelihood of accidental injuries.

Advantages:

- Compact structure, compact shape, easy to operate.

- Use high-performance permanent magnetic materials, no demagnetization.

- No electricity or other energy is required for operation.

- Advanced magnetic circuit balance design, strong holding force, almost zero residual magnetic induction, safe and reliable.

-The maximum pull-out force is 3.5 times the rated lifting force, with a high safety factor.

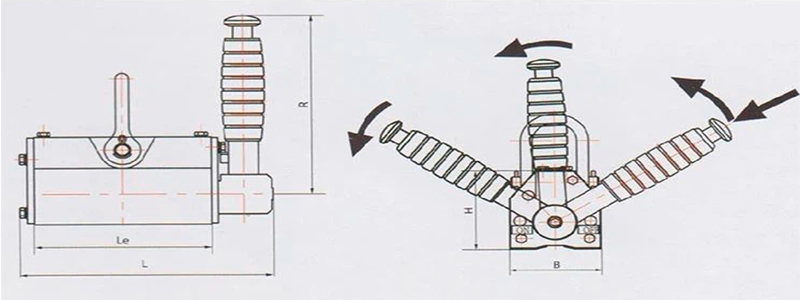

Specification of permanent magnetic lifter

| Model | Rated capacity(kg) | Max tension(kg) | Size(mm) | |||

| L | B | H | R | |||

| LSC-100 | 100 | 300 | 90 | 63 | 68 | 145 |

| LSC-400 | 400 | 1200 | 160 | 95 | 180 | 160 |

| LSC-600 | 600 | 1800 | 220 | 115 | 125 | 230 |

| LSC-1000 | 1000 | 3000 | 260 | 145 | 145 | 280 |

| LSC-1500 | 1500 | 3750 | 310 | 145 | 145 | 280 |

| LSC-2000 | 2000 | 5000 | 340 | 160 | 165 | 410 |

Working principle of permanent magnetic lifter

The magnetic force of the permanent magnetic lifter is generated by sintered NdFeB magnets. The interior of the permanent magnetic lifter consists of a static magnetic part, a reversible magnetic part, and a magnetic conductive part. When powered on, the static magnetic part and the reversible magnetic part jointly generate a concentrated magnetic field. Once attracted by the load, they will generate extremely strong magnetic force; when powered off, the reversible magnetic part rotates a certain angle to form another magnetic circuit inside the magnetic conductive part.

How to use:

- During the lifting process, first clean the surface of the workpiece to be lifted. If there is rust and burrs on the surface, clean it. It is best to make the center line of the permanent magnet crane coincide with the center of gravity of the workpiece, then place the crane on the work plane and rotate the handle from the "+" position to the limit pin position. Check whether the safety tilt block of the handle is automatically locked, and then lift.

- Overloading and passing the workpiece are strictly prohibited during lifting. The temperature of the workpiece to be lifted and the environment must not exceed 80 degrees, and there must be no severe vibration and impact.

- When lifting a cylindrical workpiece, keep the contact angle between the V-groove and the workpiece as two straight lines, so its lifting force is only 30%-50% of the rated lifting force.

- After lifting, press the handle button to separate the safety key of the handle from the safety pin. Rotate the handle from the "+" to the "-" direction to stop the pin. Put the crane in the closed state and separate the workpiece from the crane.

Permanent Magnet Lifter Application

The permanent magnet lifting system is suitable for transporting steel plates, iron blocks and cylindrical iron materials, such as mechanical parts, stamping dies and various steel materials. This lifting equipment is a lifting equipment that does not require power supply, with advanced structure, and its quality and performance have reached the advanced level of similar products in the world. It is widely used in the machinery industry, mold manufacturing industry, warehouses and transportation departments to transport steel plates, ingots and other magnetic objects.

Maintenance and safety protection

In the process of hoisting and moving, the contact surface of permanent magnet crane should be avoided as far as possible, so as not to affect the service performance and service life. When idle, the bottom of the best oil protection, wipe clean.

Tags :