-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

The Electro-Permanent Lifting Magnet (EPLM) is an advanced suction device that integrates the advantages of electromagnetic control and permanent magnet materials. It finds extensive application in various industrial sectors, particularly for heavy lifting operations. The EPLM system comprises a core electric permanent magnet assembly, along with auxiliary components such as lifting chains, cables, and an electric permanent magnet controller.

Item No :

Electro Permanent Lifting MagnetOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysElectro Permanent Lifting Magnet

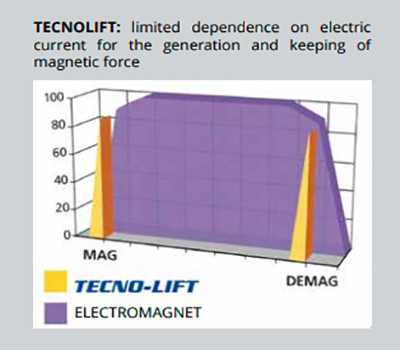

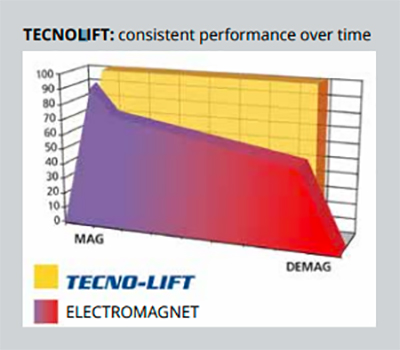

An electro-permanent jack, also known as an electric permanent magnet lifter, utilizes electric permanent magnet technology to achieve product control. Through its electronic control system, it manages and alters the distribution of internal magnetic circuits, enabling the internal permanent magnetic field to either reach equilibrium (demagnetized state) or be directed to the working magnetic pole surface (magnetized clamping state). Electrical energy is consumed only during the brief moments of magnetization and demagnetization, resulting in over 95% energy savings and significantly reduced operational costs.

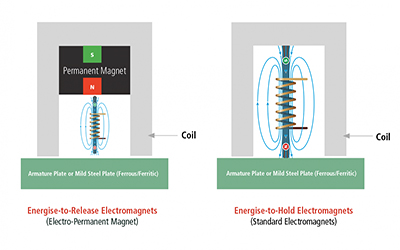

The EPLM operates based on the interaction between electromagnetic and permanent magnets. The device consists of two main components: the electromagnetic section and the permanent magnet section. The electromagnetic section includes coils and magnets that can be energized or de-energized to initiate or terminate adsorption. The permanent magnet section features strong permanent magnet materials that generate a consistent magnetic force.

During operation, when the electromagnetic coil is energized, it generates a magnetic field that interacts with the permanent magnet's field, creating a powerful suction force. This force can be used to lift or hold heavy objects for handling or assembly tasks. Upon completion of the task, disconnecting power from the electromagnetic section removes the magnetic force, allowing the object to be released effortlessly.

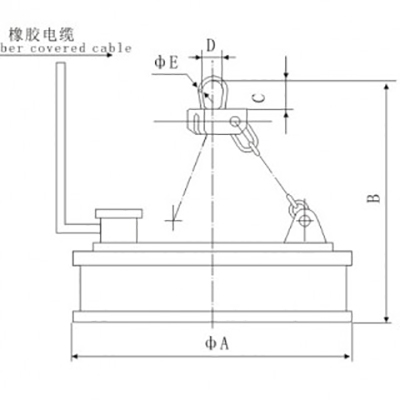

| Item | Electricity | Power (KW) | Elevating Capacity( KG) | Weight | Overall dimension( mm) | ||||

| ( A) | Steel Ball | Steel Ingot | Cutting | ( KG) | A | B | C | ||

| MW5-70L/1 | 15 | 3.3 | 2500 | 380/200 | 120/100 | 490 | 700 | 800 | 160 |

| MW5-80L/1 | 18 | 3.96 | 3000 | 480/250 | 150/130 | 620 | 800 | 800 | 160 |

| MW5-90L/1 | 26.6 | 5.85 | 4500 | 600/400 | 250/200 | 800 | 900 | 1090 | 200 |

| MW5-110L/1 | 35 | 7.7 | 6500 | 1000/800 | 450/400 | 1350 | 1100 | 1140 | 220 |

| MW5-120L/1 | 45.5 | 10 | 7500 | 1300/1000 | 600/500 | 1700 | 1200 | 1180 | 220 |

| MW5-130L/1 | 54 | 11.9 | 8500 | 1400/1100 | 700/600 | 2060 | 1300 | 1240 | 250 |

| MW5-150L/1 | 71.2 | 15.6 | 11000 | 1900/1500 | 1100/900 | 2830 | 1500 | 1250 | 350 |

| MW5-165L/1 | 75 | 16.5 | 12500 | 2300/1800 | 1300/1100 | 3200 | 1650 | 1590 | 370 |

| MW5-180L/1 | 102.4 | 22.5 | 14500 | 2750/2100 | 1600/1350 | 4230 | 1800 | 1490 | 370 |

| MW5-210L/1 | 129 | 28.4 | 21000 | 3500/2800 | 2200/1850 | 7000 | 2100 | 1860 | 400 |

| MW5-240L/1 | 154 | 33.9 | 26000 | 4800/3800 | 2850/2250 | 9000 | 2400 | 2020 | 450 |

Features:

1. Designed with comprehensive safety considerations, EPLM lifting magnets are compact, lightweight, high-strength, and highly reliable.

2. Combining permanent and electromagnetic forces, the EPLM jack is suitable for clamping and disassembly work.

3. In the event of power failure, the lifted object remains securely held, as electricity is only required for initial fixation and release, ensuring 100% operational safety.

4. Without continuous power supply, the system can handle both flat and curved plates, addressing blind spots effectively.

5. Safety interlock keys ensure simultaneous pressing of both magnetization/demagnetization buttons to prevent accidents.

6. "Point" function - When activated, this feature gradually reduces magnetic force to ensure only one plate is processed at a time, preventing unintended multiple lifts.

7. An indicator block displays the current system status.

Applications of electropermanent magnet jacks include:

1. Handling and feeding of iron plates, steel plates, and laser cutting machine materials.

2. Lifting and handling of various steel products.

3. Handling and feeding of iron and steel coils.

4. Handling and loading of iron and steel pipes.

5. Handling and feeding of forged prefabricated parts.

6. Other magnetic materials with flat surfaces and regular shapes.

Tags :