-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Electro Lifting Magnet is a powerful device used for lifting and handling magnetic materials, especially steel materials. Electro Lifting Magnet is widely used in different industrial fields, such as steelmaking, casting, mining, machinery, transportation and other industries. It usually consists of electromagnetic coils, magnet pole plates and control systems. Electro Lifting Magnet includes accessories such as cable reels, control panels and main controllers for easy operation and control.

Item No :

Electro Lifting MagnetOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysElectro Lifting Magnet

Electro Lifting Magnet is suitable for handling cast iron ingots, steel balls, steel plates, steel pipes, steel bars and various types of scrap steel. Its working principle is to use electric current to pass through the electromagnetic coil to generate a magnetic field, which attracts metal objects and fixes them on the magnet pole plate. When the current passing through the electromagnetic coil stops or reverses, the magnetic field disappears, and the metal object loses its attraction, thus achieving lifting and release.

Common support systems for permanent magnet lifting magnets include:

Steel structure: provides a strong and stable foundation for mounting the lifting magnet.

Mounting bracket: used to fix the lifting magnet to the steel structure or other equipment.

Control system: includes the power supply, control panel and wiring required to operate and monitor the permanent magnet lifting magnet.

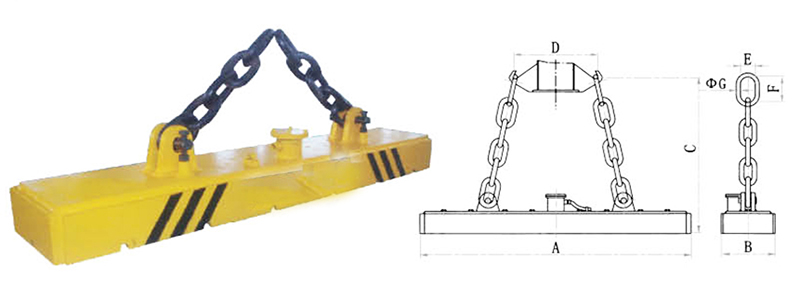

Electro Lifting Magnet Regular Dimensions

LSC84-35

| model | Cold power(kw) | Cold current(A) | Dimensions (mm) | Mass(kg) | ||||||

| A | B | C | D | E | F | G | ||||

| LSC84-9030T/1 | 0.4 | 1.9 | 900 | 350 | 900 | 350 | 110 | 180 | 32 | 185 |

| LSC84-10535T(L)/1 | 0.9(1.4) | 4.1(6.4) | 1050 | 350 | 960 | 400 | 110 | 180 | 32 | 330 |

| LSC84-14035T(L)/1 | 1.2(1.87) | 5.5(8.5) | 1400 | 350 | 940 | 500 | 110 | 180 | 32 | 430 |

| LSC84-17535T(L)/1 | 1.5(2.35) | 6.8(10.68) | 1750 | 350 | 940 | 700 | 110 | 180 | 32 | 510 |

| LSC84-21035T(L)/1 | 1.8(2.8) | 8.2(12.7) | 2100 | 350 | 920 | 800 | 110 | 180 | 32 | 600 |

| LSC84-24535T(L)/1 | 2.5(3.3) | 11.4(15) | 2450 | 350 | 980 | 850 | 110 | 180 | 32 | 720 |

| LSC84-26035L/1 | 3.35 | 15.2 | 2600 | 350 | 1050 | 850 | 110 | 180 | 35 | 855 |

| LSC84-26035L/2 | 3.1 | 14.1 | 2600 | 350 | 1080 | 850 | 110 | 180 | 35 | 900 |

LSC84-40

| model | Cold power(kw) | Cold current(A) | Dimensions (mm) | Mass(kg) | ||||||

| A | B | C | D | E | F | G | ||||

| LSC84-12040L/1 | 3 | 13.6 | 1200 | 400 | 1020 | 400 | 110 | 180 | 30 | 550 |

| LSC84-16040L/1 | 3.2 | 14.5 | 1600 | 400 | 1000 | 700 | 110 | 180 | 35 | 690 |

| LSC84-20040L/1 | 5 | 22.7 | 2000 | 400 | 970 | 800 | 110 | 180 | 35 | 840 |

| LSC84-24040L/1 | 6 | 27.3 | 2400 | 400 | 890 | 850 | 110 | 180 | 35 | 910 |

| LSC84-13042L/2 | 2.4 | 10.9 | 1260 | 420 | 1040 | 500 | 110 | 180 | 30 | 650 |

| LSC84-17042L/2 | 3.7 | 16.8 | 1680 | 420 | 1050 | 700 | 110 | 180 | 35 | 850 |

| LSC84-21042L/2 | 4 | 18.2 | 2100 | 420 | 1000 | 800 | 110 | 180 | 35 | 1050 |

| LSC84-25042L/2 | 4.8 | 21.8 | 2520 | 420 | 990 | 850 | 110 | 180 | 35 | 1250 |

LSC84-50

| model | Cold power(kw) | Cold current(A) | Dimensions (mm) | Mass(kg) | ||||||

| A | B | C | D | E | F | G | ||||

| LSC84-13050L/1 | 2.6 | 11.8 | 1300 | 500 | 1150 | 700 | 110 | 180 | 35 | 780 |

| LSC84-18050L/1 | 3.3 | 15 | 1800 | 500 | 1200 | 800 | 110 | 180 | 40 | 1180 |

| LSC84-26050L/1 | 5.1 | 23.2 | 2600 | 500 | 1250 | 850 | 110 | 180 | 45 | 1480 |

| LSC84-13050L/2 | 2.5 | 11.4 | 1300 | 500 | 1180 | 700 | 110 | 180 | 35 | 830 |

| LSC84-18050L/2 | 3.1 | 14.1 | 1800 | 500 | 1230 | 800 | 110 | 180 | 40 | 1170 |

| LSC84-26050L/2 | 4.9 | 22.3 | 2000 | 500 | 1280 | 850 | 110 | 180 | 45 | 1590 |

LSC84-65

| model | Cold power(kw) | Cold current(A) | Dimensions (mm) | Mass(kg) | ||||||

| A | B | C | D | E | F | G | ||||

| LSC84-13065L/1 | 4.5 | 20.5 | 1300 | 650 | 1050 | 600 | 100 | 220 | 40 | 1370 |

| LSC84-20065L/1 | 6.8 | 30.9 | 2000 | 650 | 1050 | 600 | 100 | 220 | 50 | 2050 |

| LSC84-26065L/1 | 9.1 | 41.4 | 2600 | 650 | 1150 | 700 | 100 | 220 | 55 | 2790 |

Example of ensuring the number of sheets transported

| Steel plate width | Model Suction and Lifting Number | Steel plate thickness (mm) | ||||||

| 6 | 8 | 10 | 12 | 16 | 20 | 32 | ||

| 1500(mm) | LSC84-13065L/1 | 10 | 7 | 6 | 6 | 5 | 4 | 3 |

| LSC84-20065TL/1 | 11 | 8 | 7 | 6 | 5 | 4 | 3 | |

| LSC84-26065TL/1 | 11 | 8 | 7 | 6 | 5 | 4 | 3 | |

| 2500(mm) | LSC84-13065L/1 | 6 | 6 | 5 | 5 | 4 | 3 | 2 |

| LSC84-20065TL/1 | 10 | 7 | 7 | 6 | 5 | 4 | 3 | |

| LSC84-26065TL/1 | 11 | 8 | 7 | 5 | 5 | 4 | 3 | |

| 4000(mm) | LSC84-13065TL/1 | * | * | * | 3 | 2 | 2 | 1 |

| LSC84-20065L/1 | * | 3 | 4 | 4 | 3 | 2 | 2 | |

| LSC84-26065L/1 | 5 | 5 | 5 | 5 | 4 | 3 | 2 | |

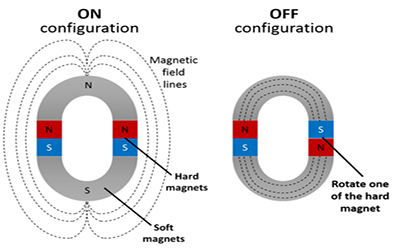

Advantages of electro-permanent magnet lifts

1. Enhance safety: Electric permanent magnet lifting magnets provide safe and reliable lifting solutions, minimize the risk of accidents and ensure the safety of operators and surrounding people.

Complete.

2. Easy operation: These magnets provide easy and efficient operation with simple controls, allowing operators to lift and release loads quickly and easily.

3. Improve productivity: Electric permanent magnet lifting magnets can handle materials quickly and efficiently, reducing downtime and increasing productivity in various industries.

4. Versatility: These magnets are versatile and can lift a variety of materials, including steel plates, profiles, pipes, and even irregularly shaped objects, making them suitable for a variety of applications

application.

5. Energy efficiency: Electric permanent magnet lifting magnets only consume electricity during the magnetization and demagnetization stages, which can significantly save 95% of energy compared with traditional permanent magnets.

6. No power required during operation: Once the load is lifted, the electro-permanent lifting magnet does not require continuous power, thereby reducing reliance on electrical connections and allowing for greater

Mobility.

7. Precise and Controlled Placement: These magnets provide precise positioning and controlled load placement, ensuring accurate alignment and reducing the risk of damage during handling.

8. Reduced Maintenance: Electric permanent magnet lifting magnets have extremely low maintenance requirements, thus saving costs and increasing uptime of lifting operations.

9. Improved magnetic properties: With the ability to control magnetic field strength, electro-permanent lifting magnets provide optimized lifting capabilities and a firm grip on materials, thereby improving overall lifting performance.

Operating rules or precautions for lifting magnets:

Before each use, the magnets are visually inspected. We must determine whether the magnets look intact from the outside. Then we check whether the controller parameters are adjusted correctly, the wires are connected correctly, and the magnetization and demagnetization are normal.

Before using the magnets, the operator must read the instructions. They should also be confident in their basic safety knowledge. No unauthorized person should operate the magnets.

Pay attention to the load and avoid carrying loads that exceed the lifting capacity of the lifting magnets. The capacity of the lifting magnets can be modified according to your load handling requirements.

Pay attention to the operating temperature. Magnets can sometimes be customized to meet your precise temperature requirements. Use the magnets within the allowed temperature range, because the higher the temperature, the faster the magnetic force decays.

Avoid any form of collision or vibration during operation.

Try to keep the load balanced and the weight evenly distributed under the magnets.

Make sure the load is in full contact with the magnets, do not magnetize the magnets before this.

Tags :