-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

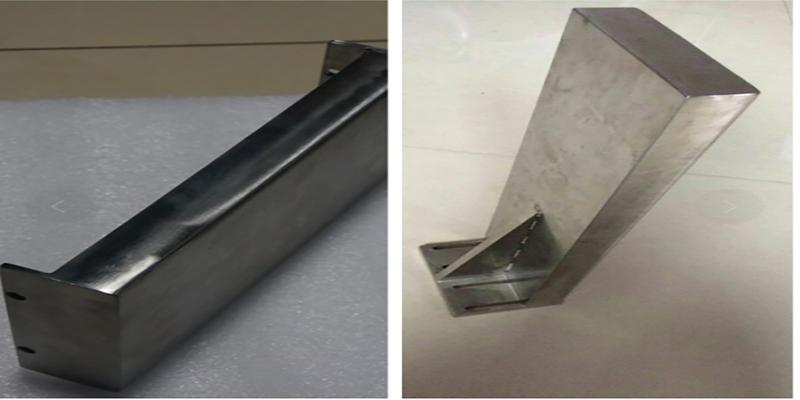

Magnetic Sheet Separator

In the metalworking industry, magnetic sheet separators - also called sheet fanners or spreading magnets - are used for the safe and damage-free magnetic separation and removal of single sheets from a stack of metal sheets. The sheet separators are positioned on the side of the stack of sheets and direct a magnetic flux into the sheets. This results in a homopolar magnetization of the sheets, which then repel each other. The topmost sheet can now be safely removed as a single sheet. Sheet separators are successfully used for both manual and automatic removal.

Item No :

Magnetic Sheet SeparatorsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysThe Magnetic Sheet Separator is a product that offers efficient magnetic separation for various applications. Its three key features include:

1. Versatility: The Magnetic Sheet Separator is designed to separate and lift magnetic sheets of different sizes and thicknesses. It can easily handle various materials, such as ferrous steel, iron, and magnetic laminates.

2. Strong Magnetic Force: This product utilizes powerful magnets that generate a strong magnetic field. The strong magnetic force ensures effective separation and prevents sheets from sticking together, allowing for smooth and seamless handling.

3. Easy to Use: The Magnetic Sheet Separator is user-friendly, featuring a simple and intuitive design. It can be easily adjusted to accommodate different sheet thicknesses and can be quickly mounted or dismounted as needed. Its ergonomic design enhances operational efficiency and saves time.

Overall, the Magnetic Sheet Separator is a versatile and efficient solution for magnetic sheet separation, with its key features of versatility, strong magnetic force, and user-friendly design. It provides effective handling and separation of magnetic sheets, making it an ideal choice for a wide range of industries and.

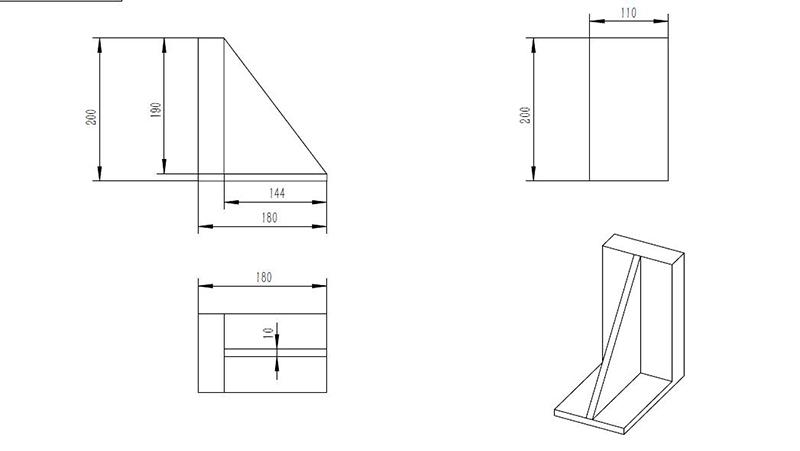

Sheet separators warrant a stable and easy-to-integrate system that consists of a magnetic core, a stainless-steel cover and a rear steel plate with mounting holes.Depending on the required spreading effect, we offer sheet separators with magnets made of neodymium-iron-boron (NdFeB) or hard ferrite (HF). The sheet thickness and size of the metal sheets are decisive factors in the selection of the right magnetic material.

Features:

1. Lifetime Guarantee of Permanent Magnetic Strength

2. Less than 4-5% magnetic loss in 100 years

3. Durable 304 Stainless Steel construction standard

4. Finest of Magnetic Materials used meeting with IMA or MMPA standards

5. Can be applied to manual as well as robotic press-feeding systems

6. Lift handle and counter-balanced base for stability

7. Special requirements, can be customized.

Benefits:

1. Increase Safety, Productivity, Uptime & Profitability by reducing double-blanking

2. Reduce scrap loss

3. Reduce worker fatigue

Magnetic Sheet Separator Specification:

Performance chart was developed by testing of standard mill-run 16-24" mild steel sheet. This chart was developed around common sheet sizes. Standard sheet fanners can handle 30-to-9-gauge sheet (3-3.8mm) thickness metal applications.

| Part Number | A (") | B (") | C (") | D (") |

| Series 1 -- For Light Gage Steel | ||||

| MSS1-1427 | 7.25 | 5.25 | 1.75 | 5 |

| MSS1-1428 | 10.25 | 5.25 | 1.75 | 5 |

| MSS1-1429 | 13.25 | 5.25 | 1.75 | 5 |

| MSS1-1430 | 16.25 | 5.25 | 1.75 | 5 |

| Series 2 -- For Medium Gage Steel | ||||

| MSS2-1431 | 10.25 | 6.25 | 2.75 | 8 |

| MSS2-1432 | 13.25 | 6.25 | 2.75 | 8 |

| MSS2-1433 | 16.25 | 6.25 | 2.75 | 8 |

| MSS2-1434 | 19.25 | 6.25 | 2.75 | 8 |

| Series 3 -- For Heavy Gage Steel | ||||

| MSS3-1435 | 10.25 | 6.25 | 3.75 | 10 |

| MSS3-1436 | 13.25 | 6.25 | 3.75 | 10 |

| MSS3-1437 | 16.25 | 6.25 | 3.75 | 10 |

Added specification code

|

Item Number |

Specification |

|

MSF220×170×50 |

MSF220×170×50mm |

|

MSF260×100×40 |

MSF260×100×40mm |

|

MSF280×150×50 |

MSF280×150×50mm |

|

MSF280×80×30 |

MSF280×80×30mm |

|

MSF380×210×40 |

MSF380×210×40mm |

|

MSF380×120×30 |

MSF380×120×30mm |

|

MSF422×156×46 |

MSF422×156×46mm |

|

MSF520×100×30 |

MSF520×100×30mm |

|

MSF550×100×30 |

MSF550×100×30mm |

Cooperative customer case:

Magnetic Sheet Separators Package: by wood case:

How to choose the correct delimiter size depends on the following parameters:

The thickness of the metal plate.

The size of the bed sheet.

The height of the pile.

The surface quality of the board.

The condition of the paper (moisture, oil, etc.).

When choosing a separator, we recommend following the following guidelines:

Maximum surface area separated by each separator:

Suitable for ordinary boards with a maximum area of 0.3m2

Suitable for boards with an oil containing area of up to 0.15m2

If paper is to be lifted through an automatic process, more separators are required and should be placed around the stack. In addition, a mechanical system for moving paper is required.

Application scenarios of Magnetic Sheet Separators:

Tags :