-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic pulley, also referred as pulley magnet, is generally installed on the end of conveyer belt and suit very well to automatic separation of iron scuff, plate, block or other ferromagnetic material in large batch of dry material like grain, mineral, gravel, plastic, wood, cullet and wastage. Magnetic pulley can utilize either sintered ferrite magnets or rare earth permanent magnets. The maximum magnetic field strength can reach 15000 Gauss. The surface material of magnetic pulley can select from 304 and 316 stainless steel which has excellent corrosion resistance and no pollution. Both ends of pulley magnet can connect with electric motor. Magnetic pulley can form an automatic separation system after combining with the conveyer belt.

Item No :

Magnetic PulleyOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysThe Magnetic Pulley is a versatile and efficient device used in various industrial applications. It is specifically designed to attract and separate ferrous materials from non-ferrous ones, ensuring optimal material purity and processing efficiency. With its powerful magnetic field generated by the rotating drum, the Magnetic Pulley is capable of effortlessly capturing and removing unwanted metal contaminants from conveyor belts, chutes, and other material handling systems. This results in improved product quality, increased equipment lifespan, and reduced downtime. Whether in recycling plants, mining operations, or bulk material handling facilities, the Magnetic Pulley offers reliable and cost-effective magnetic separation, making it an indispensable component in diverse industrial.

Features:

1. The drum body can be made from cheap ferrite magnets .The max magnetic strength can be up to 15000GS if made from powerful rare earth magnets.

2. Surface material is 304 or 316L stainless steel which is in good corrosion resistance.

3. No electric power required for magnetic field generation.

4. A special design for two ends of the pulley is in order to connect with a motor.

5. An automatic separation system can be formed if the pulley works together with the conveyor.

6. Special requirement can be custom made.

Specifications:

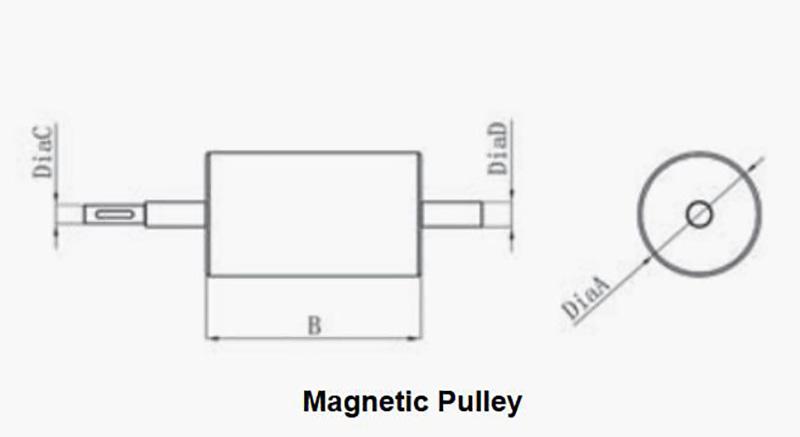

| MODEL NO | Dia A | B | DiaD | DiaC | Weight(Kg) |

| PM2030 | 200 | 350 | 40 | 30 | 33 |

| PM2040 | 200 | 450 | 40 | 30 | 42 |

| PM2050 | 200 | 550 | 40 | 30 | 51 |

| PM2060 | 200 | 650 | 40 | 30 | 60 |

| PM2070 | 200 | 750 | 40 | 30 | 69 |

| PM2080 | 200 | 850 | 40 | 30 | 78 |

| PM2090 | 200 | 950 | 40 | 30 | 87 |

| PM20100 | 200 | 1050 | 40 | 30 | 96 |

| PM3030 | 300 | 350 | 50 | 40 | 74 |

| PM3040 | 300 | 450 | 50 | 40 | 95 |

| PM3050 | 300 | 550 | 50 | 40 | 116 |

| PM3060 | 300 | 650 | 50 | 40 | 137 |

| PM3070 | 300 | 750 | 50 | 40 | 158 |

| PM3080 | 300 | 850 | 50 | 40 | 179 |

| PM3090 | 300 | 950 | 50 | 40 | 200 |

| PM30100 | 300 | 1050 | 50 | 40 | 221 |

| PM4030 | 400 | 350 | 60 | 50 | 131 |

| PM4040 | 400 | 450 | 60 | 50 | 168 |

| PM4050 | 400 | 550 | 60 | 50 | 205 |

| PM4060 | 400 | 650 | 60 | 50 | 242 |

| PM4070 | 400 | 750 | 60 | 50 | 279 |

| PM4080 | 400 | 850 | 60 | 50 | 316 |

| PM4090 | 400 | 950 | 60 | 50 | 353 |

| PM40100 | 400 | 1050 | 60 | 50 | 390 |

Cooperative customer case:

Quality inspection system:

Before shipment, 10% of our Half Magnetic Drum will be randomly inspected. Test Gauss performance, and surface flaws. And issue a product test report to send to the customer.

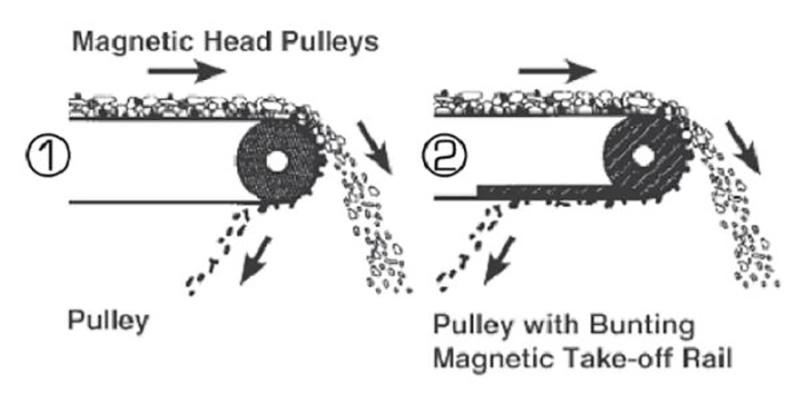

The working principle of Magnetic Pulley:

The impurities of iron pollutants enter the magnetic field of the pulley, and the impurities are attracted and kept on the belt until they reach the bottom, leave the magnetic field, and are discharged separately. The cleaned non-magnetic material is discharged through the pulley in a normal trajectory.

Applications:

Magnetic Pulleys always are placed at the head of conveyor belt to separate iron particle, iron scrap, tramp iron and other ferromagnetic objects from more bulk dry material flow such as iron ore,grain,sand,gravel,plastics,wood,waste,cullet,rubber,etc

Package

To ensure the safe delivery of products to customers, we use wooden crates for packaging.

Tags :