-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic Grill

Magnetic Grill Also known as the hopper magnetic grill.Hopper magnets are useful in many different magnetic separation applications. They use a high-density magnetic field that has been expertly configured for optimal removal of ferrous metal contamination. Ceramic grate magnets excel at removing ferrous fines, fragments, and small metal objects as product flows through them.

The hopper magnet protects your processing machinery against ferrous impurities. Magnetic filter bars are fixed onto stainless steel frameworks, when anything containing iron substances passes through the framework, Iron particles are attracted to the bar magnets by magnetic fields. As a result, your equipment and facilities will be safe and sound, and your products will be safe for consumption.

Item No :

Magnetic GrillOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysThe Magnetic Grill, also referred to as Magnetic Grate or Grate Magnets, is a highly efficient and innovative solution designed for applications requiring the removal of ferrous contaminants from dry bulk materials. This specialized equipment consists of a series of magnetic tubes or rods encased in a stainless-steel housing. The magnetic tubes are strategically placed to create a magnetic field that attracts and captures unwanted metal particles as the material flows through the equipment. This process ensures the purity and quality of the final product, preventing damage to downstream equipment and ensuring product integrity. The Hopper Magnet variant of the Magnetic Grill is specifically designed for use in hoppers or chutes, providing effective magnetic separation in gravity-fed systems. With its robust construction, easy installation, and excellent magnetic strength, the Magnetic Grill is a reliable solution for industries such as food processing, pharmaceuticals, chemicals, and plastics, where product purity is of utmost.

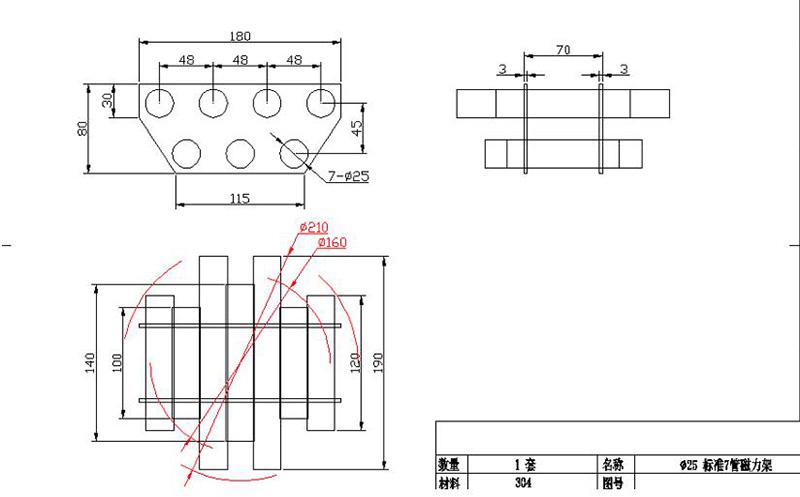

Round magnetic grate model:

Size of regular style:

| Shelf Diameter | Layer QTY | Height H | Distance A | Distance B | Bar QTY |

| MM | Layer | MM | MM | MM | PCS |

| ∅100 | 1 | 40 | 50 | 40 | 2 |

| 2 | 80 | 50 | 40 | 3 | |

| ∅150 | 1 | 40 | 50 | 40 | 3 |

| 2 | 80 | 50 | 40 | 5 | |

| ∅200 | 1 | 40 | 50 | 40 | 4 |

| 2 | 80 | 50 | 40 | 7 | |

| ∅250 | 1 | 40 | 50 | 40 | 5 |

| 2 | 80 | 50 | 40 | 9 | |

| ∅300 | 1 | 40 | 50 | 40 | 6 |

| 2 | 80 | 50 | 40 | 11 | |

| ∅350 | 1 | 40 | 50 | 40 | 7 |

| 2 | 80 | 50 | 40 | 13 | |

| ∅400 | 1 | 40 | 50 | 40 | 8 |

| 2 | 80 | 50 | 40 | 15 | |

| ∅450 | 1 | 40 | 50 | 40 | 9 |

| 2 | 80 | 50 | 40 | 17 | |

| ∅500 | 1 | 40 | 50 | 40 | 10 |

| 2 | 80 | 50 | 40 | 19 |

Rectangle Grate Magnets:

| Grate size | Layer | H | A | B | Bar QTY |

| MM | QTY | MM | MM | MM | PCS |

| 100*100 | 1 | 40 | 50 | 40 | 2 |

| 2 | 80 | 50 | 40 | 3 | |

| 150*150 | 1 | 40 | 50 | 40 | 3 |

| 2 | 80 | 50 | 40 | 5 | |

| 200*200 | 1 | 40 | 50 | 40 | 4 |

| 2 | 80 | 50 | 40 | 7 | |

| 250*250 | 1 | 40 | 50 | 40 | 5 |

| 2 | 80 | 50 | 40 | 9 | |

| 300*300 | 1 | 40 | 50 | 40 | 6 |

| 2 | 80 | 50 | 40 | 11 | |

| 350*350 | 1 | 40 | 50 | 40 | 7 |

| 2 | 80 | 50 | 40 | 13 | |

| 400*400 | 1 | 40 | 50 | 40 | 8 |

| 2 | 80 | 50 | 40 | 15 | |

| 450*450 | 1 | 40 | 50 | 40 | 9 |

| 2 | 80 | 50 | 40 | 17 | |

| 500*500 | 1 | 40 | 50 | 40 | 10 |

| 2 | 80 | 50 | 40 | 19 |

Features:

1. The material of the shelf and pipe is 304 or 316L stainless steel, which is corrosion-resistant and pollution-free.

2. The standard magnetic frame is made of a metal frame and a 25mm diameter magnetic rod arranged at a distance of 50mm from the center, and then fixed and assembled or welded by screws.

3. The surface can be polished to meet the requirements of food or drug use grade.

4. The standard working temperature ≤ 80°C, and the maximum working temperature can reach 350°C under special requirements.

5. The magnetic strength grade:

2800Gs+,4000Gs+6000Gs,8000Gs,10000Gs,11000GS, 12000Gs,13000Gs+,14000Gs+;

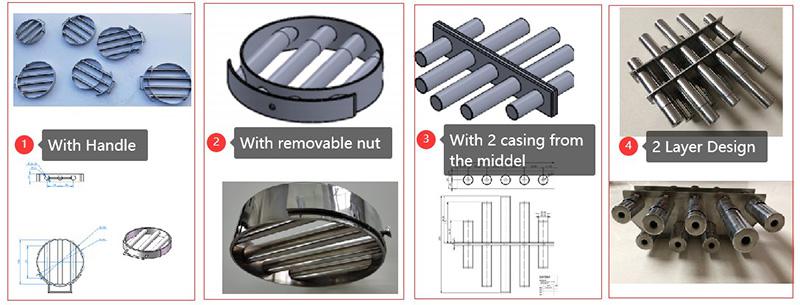

6. Ordinary type, easy to clean type, type with deflector rod or deflector, square, round and other special specifications required by customers can be provided.

Cooperative customer case:

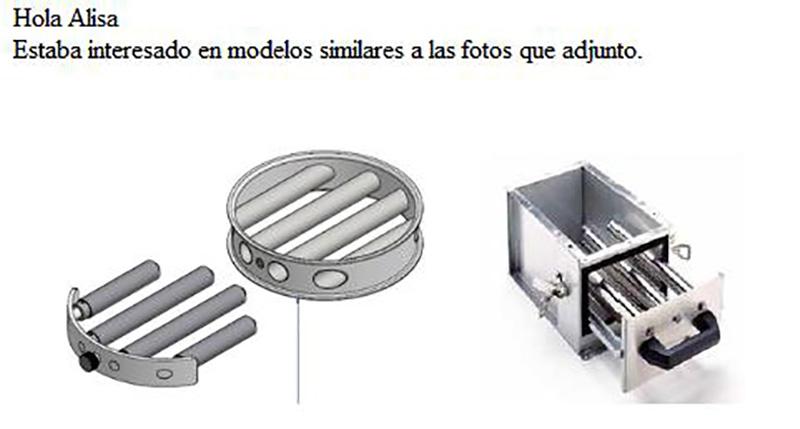

We can design solutions for customers according to their needs and provide drawings for customers to confirm.

1. Customers used in coffee production

The design drawings we provide to customers:

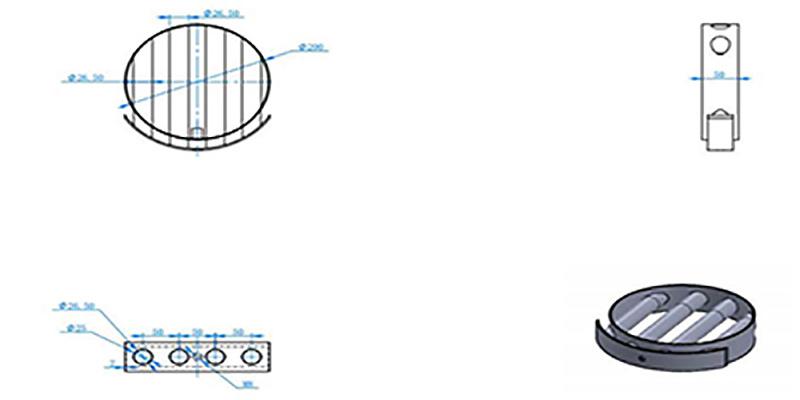

2.Customers used in injection molding machines

Why choose us?

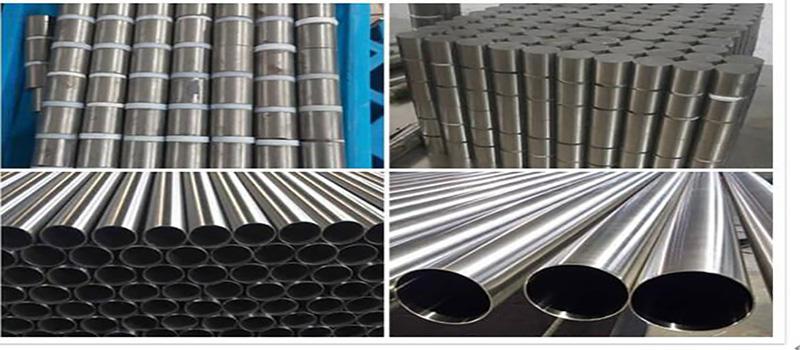

1. Inventory system

Our warehouse has a large amount of conventional raw materials and stainless-steel pipes. We can directly produce hopper magnet according to your needs without repurchasing raw materials.

The delivery time of conventional products is usually 5-7 days. We can provide you with multiple modes of transportation such as air, sea and express or land.

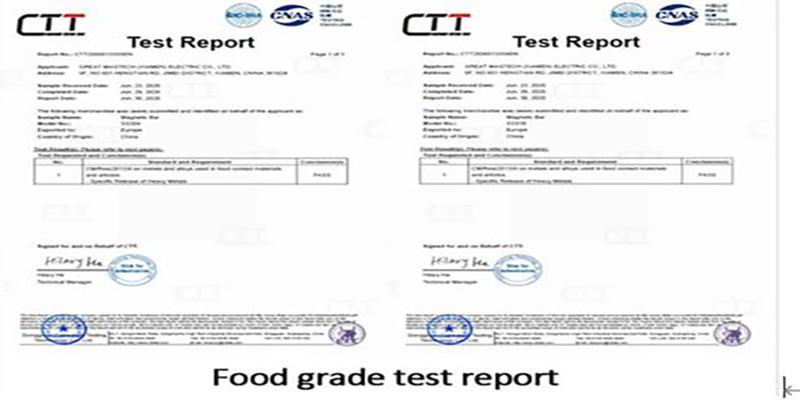

2. Quality inspection system

Our products have passed China International CNAS CTT testing agency accredited testing, You can use it without safety concerns.

3.Package of Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

We will choose different packing methods according to the different shipping methods to ensure that the products will not be damaged during shipping. So far, our customers have 0 complaints about the packaging of our products.

By express or air:Bubble bag-foam board-iron sheet insulation--double corrugated box.

By sea: Wood Carton

Pallet:

4.After-sales Service:

Our response will be always available within 12 hours.

Products and packing pictures before shipment.

Offer Invoice, packing list and documents timely.

Shipping notice and goods arrival notice at timely.

Magnet application suggestion and tips.

How to choose a Magnetic Grill, Magnetic Grate, Grate Magnets, Hopper Magnet:

Hopper Magnets are made up of a combination of multiple magnetic rods, so the main thing to judge a Grate Magnet is the quality of the rods. Of course, in addition to the magnetic rods, it is also necessary to look at the combination of the magnetic holder sequence design.

The magnetic rods are made of strong magnets and magnetic guide plates arranged in a prescribed order, but because the rods are sealed, it is impossible to disassemble them to see the inside condition. So how do we determine if the magnet and magnetic guide of this rod is evenly ordered and if the magnetic induction line is even? At this time, we can look at the magnetic lines, you can sprinkle a little iron powder, the distribution of iron powder is the distribution of magnetic induction lines, so as to judge whether the order of the magnets and iron sheet of this magnetic rod is reasonable.

In addition to the magnetic induction wire, we also need to see if the exterior of the magnet is smooth and free of burrs, sealed in place. The magnet material inside should not be exposed on the outside to avoid direct contact with the material, which may pollute the material and the environment.

In order to have a good experience when you buy a LSC Magnet, please tell us your usage situation, because the application environment, the design of the magnetic rack and the magnetic bar have different requirements.

Applications:

Magnetic grids are extremely efficient at removing fine ferrous contamination from free flowing products such as powders, granules, liquids and emulsions. They are easily placed in hoppers, product intake points, chutes and at finished goods outlet points.

Contaminations such as rust and fine ferrous dust from machinery wear are often too small to be detected by a Metal Detector but are easily removed by these highly efficient magnetic grids.

Tags :