-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

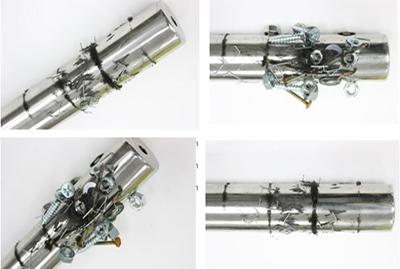

Magnetic rod

Magnetic rods are constructed with strong permanent magnets with a stainless steel shell. Either round or square shape bars are available for customers' requirements for special applications. A magnetic Bar is used for removing ferrous contaminants from free-flowing material. All the ferrous particles like bolts, nuts, chips, and damaging tramp iron can be caught and held effectively. So it provides a good solution of material purity and equipment protection. The magnetic Bar is the basic element of the grate magnet, magnetic drawer, magnetic liquid traps, and magnetic rotary separator.

Item No :

Magnetic barOrder(MOQ) :

1Product Origin :

ChinaLead Time :

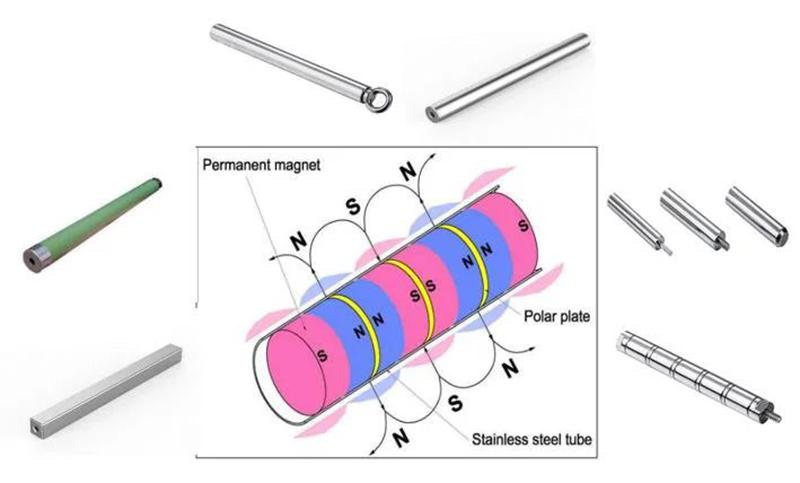

7-10daysThe Magnetic rod is a versatile product designed for various industrial applications. It consists of a cylindrical magnet enclosed in a stainless steel tube, providing a strong magnetic field for efficient separation and removal of ferrous contaminants from different materials.

With its powerful magnetic force, the Magnetic bar effectively attracts and captures ferrous particles, preventing them from contaminating production processes and causing damage to downstream equipment. It is commonly used in industries such as food processing, pharmaceuticals, ceramics, and recycling.

Advantages of magnetic rods:

1. Ferrous Contaminant Separation: The Magnetic bar can easily separate ferrous contaminants or impurities from materials, ensuring product purity and quality.

2. Magnetic Attraction: The strong magnetic field generated by the bar effectively attracts and retains ferrous particles, minimizing the risk of contamination.

3. Equipment Protection: By removing ferrous contaminants, the Magnetic bar helps protect downstream machinery, such as crushers, mills, and mixers, from potential damage, prolonging their lifespan and reducing costs.

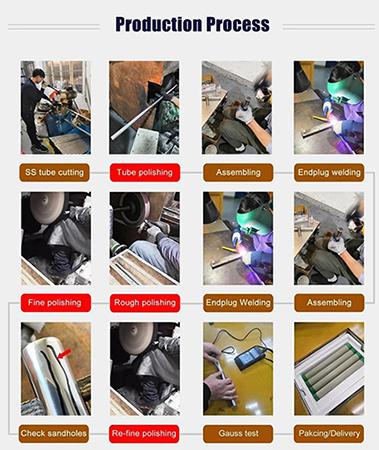

Process of Magnetic Rod:

Magnetic Rod Specification:

| Magnetic strength | Working Temperature(°C) | |||||||

| Steel tube outside diameter | 2500GS | 5000GS | 6000GS | 7000GS | 8000GS | 10000GS | 12000GS | 13000GS |

| Ф6(0.24") | 350°C | - | - | - | - | - | - | - |

| Ф8(0.31") | 350°C | - | - | - | - | - | - | - |

| Ф9(0.35") | 350°C | - | - | - | - | - | - | - |

| Ф10(0.39") | 350°C | - | - | - | - | - | - | - |

| Ф 12(0.47") | 350°C | 350°C | - | - | - | - | - | - |

| Ф16(0.63") | 350°C | 350°C | 350°C | - | - | - | - | - |

| Ф19 (0.75") | 350°C | 350°C | 350°C | 180°C | - | - | - | - |

| Ф20.3(0.80") | 350°C | 350°C | 350°C | 180°C | - | - | - | - |

| Ф22 (0.85") | 350°C | 350°C | 350°C | 180°C | 180°C | - | - | - |

| Ф25 (1.00") | 350°C | 350°C | 350°C | 180°C | 180°C | 180°C | 180°C | 180°C |

| Ф32 (1.25") | 350°C | 350°C | 350°C | 180°C | 180°C | 180°C | 180°C | 180°C |

| Ф38 (1.50") | 350°C | 350°C | 350°C | 180°C | 180°C | 180°C | 180°C | 180°C |

| Ф50 (1.75") | 350°C | 350°C | 350°C | 180°C | 180°C | 180°C | 180°C | 180°C |

| Ф63(2.48") | 350°C | 350°C | 350°C | 180°C | 180°C | 180°C | 180°C | 180°C |

Features:

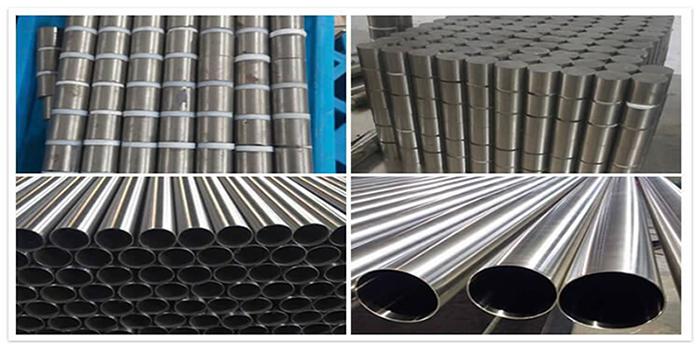

1. Standard round bar has a length of 25 mm (1 inch) diameter. As required, it can reach a maximum length of 2500mm. Magnetic tubes or other different shapes and dimensions are also available.

2. 304 or 316L stainless steel are available for pipeline material which can be fine polished and meet the standard of the food or pharmacy industry.

3. Standard working temperature≤80℃, and maximum working temperature can reach 350℃ as

required.

4. Various kinds of ends like nail head, thread hole, double screw bolt are also available.

5. Different kinds of magnets like Forum magnet or other rare earth magnets are available to meet every customer’s requirement. The maximum magnetic strength of 25mm (1 inch) diameter can reach 15,000GS.

OEM/ODM Service

All shape and size bars are available for customers desiring special applications.

|

Flat surface |

Threaded hole |

Lifting ring |

Threaded head |

|

|

|

|

|

What should I do before I purchase a magnetic bar?

1. Confirm the shape and size of the magnetic bar:

Our standard stainless-steel pipe is 25 mm. (1 inch) in diameter, and the length required by each customer does not exceed 2500 mm.

2. Confirm the gauss of the magnetic bar: 2500 Gs or 8000 Gs or 10000Gs or 12000Gs or 13000Gs 14000GS;15000Gs

3. Confirm the maximum working temperature:

There are 6 series for customers to choose

●N series temperature up to 80 degrees Celsius

●M series up to 100 degrees Celsius

●H series temperature up to 120 degrees Celsius

●The SH series can reach up to 150 degrees Celsius

●UH series up to 180 degrees Celsius

EH series up to 200 degrees Celsius

4. Confirm whether the material is corroded;

5. Confirm that the magnetic tube cover: is 316L or 304 stainless steel.

6. Confirm the threaded hole of the solenoid:

1) There are threaded holes on both ends, easy to install.

2) Tap a threaded hole on one end, and perform flat welding on the other end.

3) Both ends are flat welded.

7. Confirm the number of electromagnetic tubes: the price of different quantities is different; the price of more quantities is lower.

Why choose us?

1. Inventory system

Our company has a large amount of regular inventory.If you are a regular specification,We can ship the goods on the day of payment.

If it’s a custom size.We have a lot of assembly materials.Can be assembled within 14 days after delivery.

2. Quality inspection system

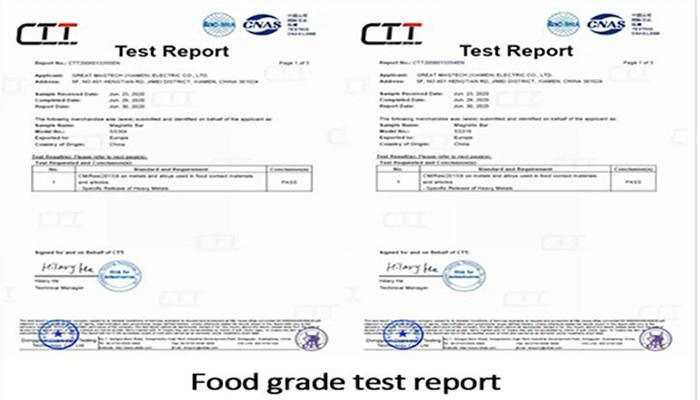

Our products have passed China International CNAS CTT testing agency accredited testing, You can use it without safety concerns.

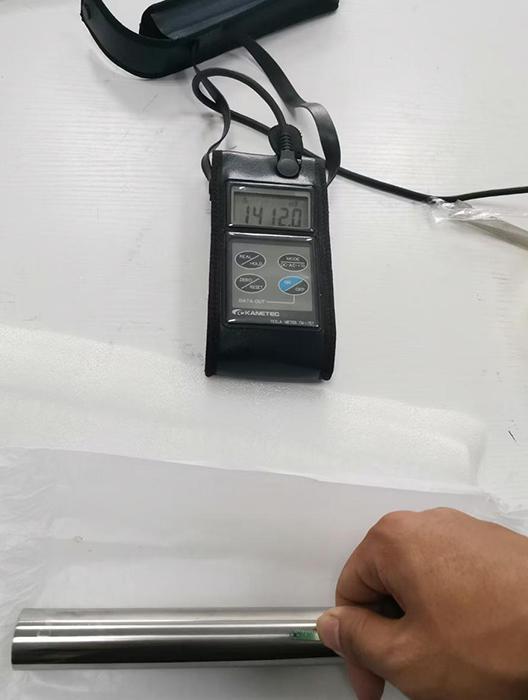

Before shipment, 10% of our magnet's bar will be randomly inspected. Test Gauss performance and surface flatness, and surface flaws. And issue a product test report to send to the customer.

3. Packaging

To ensure the safety of the magnetic bar during transportation, we will utilize a sturdy internal foam box, a double-wall corrugated box, or plastic pipes. This packaging is designed to protect the magnet from any potential damage and prevent any interference from the magnetic field. Our team is committed to providing top-notch packaging that guarantees the delivery of your magnet in perfect condition.

Application of magnetic rod filters:

The magnetic rod is mainly used to filter all kinds of fine powders, as well as iron-containing impurities and other materials with magnetism in liquids and semi-liquids. Magnetic rods are mainly used in plastics, food, environmental protection, filtration, chemical, electric power, building materials, ceramics, medicine, powder, mining, coal, and other industries.

The magnetic rod is composed of an inner magnetic core and an outer cladding. The magnetic core includes a cylindrical magnet block and a magnetic conductive sheet.

A good magnetic rod should have a uniform distribution of magnetic induction lines, and the maximum magnetic induction intensity point distribution should fill the entire magnetic rod as much as possible. Because it is generally placed in the moving product transmission line, the surface of the magnetic rod should be smooth and have little resistance, and it does not contain harmful substances to the environment, so as to avoid contaminating materials and the environment.

Our Team Work Plan:

1. Continuously effort to get some new technology to meet customers’ requirements.

2. Reply to your query within 12 hours

3. 3 days for magnet sample made

4. Timely Lead time in 3-10 days

5. Quality control from material prepared to products finished. And apply the products test report.

6. Any query we would follow up after-sales

Tags :