-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

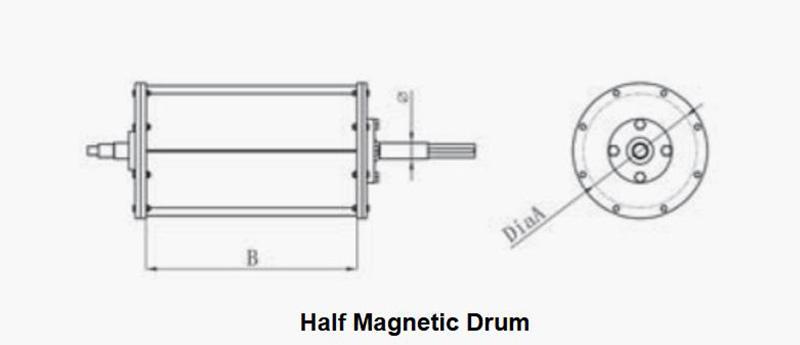

Half Magnetic Drum

Half Magnetic Drum is also named half magnetic roller which is composed of a revolving round stainless steel cover and a shaft to generate a half disc (180 degree) stationary magnetic field . An automated separating system is formed if the drum is driven by a motor.

Item No :

Half Magnetic DrumOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysIntroducing the Half Magnetic Drum, a revolutionary product designed for efficient separation of magnetic materials. This high-performance device combines cutting-edge technology with exceptional magnetism to enhance productivity and streamline processes. With its unique magnetic properties, the Half Magnetic Drum offers superior magnetic separation capabilities, making it ideal for applications in industries like mining, recycling, and bulk handling. Experience the power of the Half Magnetic Drum, and unlock a new level of efficiency, reliability, and cost-effectiveness in your.

Features:

1.Continuous self-cleaning design is suitable for automated production line.

2. Surface material is 304 or 316L stainless steel which is in good corrosion resistance.

3. No electric power required for magnetic field generation.

4. Magnetic strength can be chosen by customer.

Specifications:

| MODEL NO | Dimension(mm) | Weight(Kg) | ||

| Dia A | B | Φ | ||

| MDM2130 | 215 | 300 | 25 | 29 |

| MDM2135 | 215 | 350 | 25 | 34 |

| MDM2140 | 215 | 400 | 25 | 39 |

| MDM2145 | 215 | 450 | 25 | 44 |

| MDM2150 | 215 | 500 | 25 | 49 |

| MDM2160 | 215 | 600 | 25 | 59 |

| MDM2170 | 215 | 700 | 25 | 69 |

| MDM2180 | 215 | 800 | 25 | 79 |

| MDM2190 | 215 | 900 | 25 | 89 |

| MDM2110 | 215 | 1000 | 25 | 99 |

| MDM3130 | 315 | 300 | 25 | 62 |

| MDM3135 | 315 | 350 | 25 | 72 |

| MDM3140 | 315 | 400 | 25 | 82 |

| MDM3145 | 315 | 450 | 25 | 92 |

| MDM3150 | 315 | 500 | 25 | 102 |

| MDM3160 | 315 | 600 | 25 | 122 |

| MDM3170 | 315 | 700 | 25 | 142 |

| MDM3180 | 315 | 800 | 25 | 162 |

| MDM3190 | 315 | 900 | 25 | 182 |

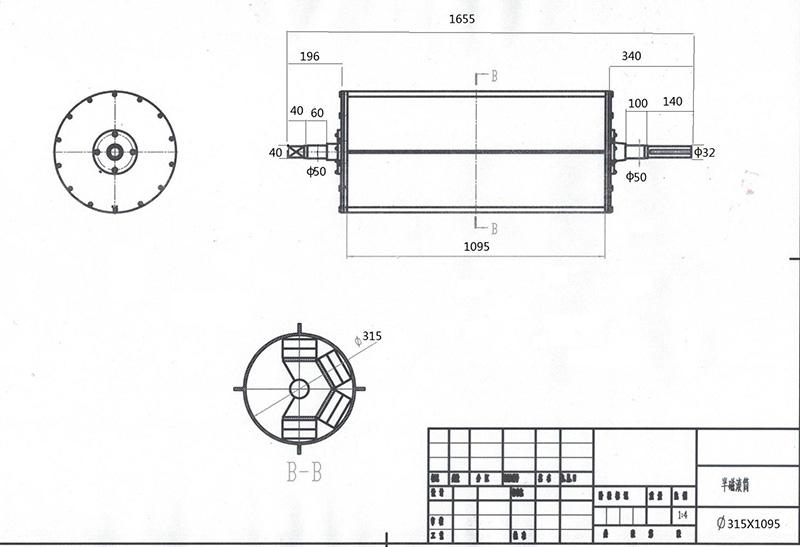

| MDM3110 | 315 | 1000 | 28 | 202 |

| MDM3111 | 315 | 1100 | 28 | 222 |

| MDM4030 | 400 | 300 | 28 | 100 |

| MDM4035 | 400 | 350 | 28 | 116 |

| MDM4040 | 400 | 400 | 28 | 132 |

| MDM4045 | 400 | 450 | 28 | 148 |

| MDM4050 | 400 | 500 | 28 | 164 |

| MDM4060 | 400 | 600 | 28 | 180 |

| MDM4070 | 400 | 700 | 28 | 196 |

| MDM4080 | 400 | 800 | 35 | 212 |

| MDM4090 | 400 | 900 | 35 | 228 |

| MDM4010 | 400 | 1000 | 35 | 244 |

| MDM4011 | 400 | 1100 | 35 | 260 |

| MDM4012 | 400 | 1200 | 35 | 276 |

Cooperative customer case:

Quality inspection system:

Before shipment, 10% of our Half Magnetic Drum will be randomly inspected. Test Gauss performance, and surface flaws. And issue a product test report to send to the customer.

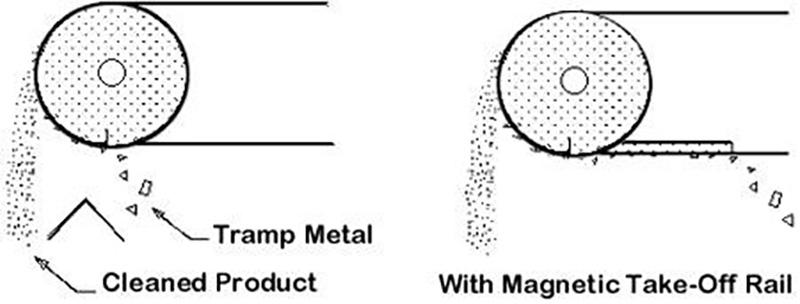

How a Magnetic Pulley works?

Magnetic Separator Magnetic Pulley is a self-cleaning magnet that removes foreign tramp metals from bulk materials on a belt conveyor. The magnetic field adheres ferrous contaminants to the belt as the clean product passes over the head pulley. Tramp metals from the underflow can be safely captured in a bin to be discarded. A magnetic take-off rail conveys captured tramp metal further down the return side of the conveyor. The take-off rail paired with the IMT Magnetic Head Pulley allows for a more convenient and smoother release of retained tramp metal-reducing belt wear while discharges in a suitable location.

Applications:

Half Magnetic Drum is mainly used to remove or sort ferrous fines, tramp iron and other ferro magnetic materials from bulk dry material flow such as iron ore, grain,sand,gravel,plastics,wood,waste, cullet, etc.

Package

To ensure the safe delivery of products to customers, we use wooden crates for packaging.

Tags :