-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

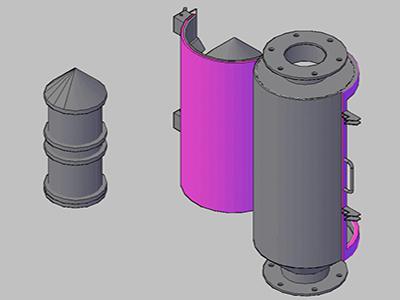

Bullet Magnets

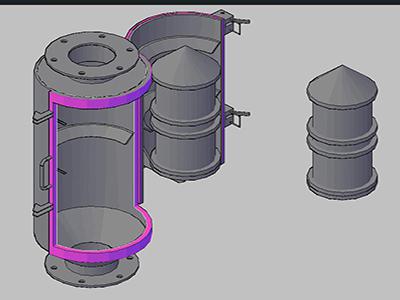

Bullet Magnet is composed of a powerful magnetic core shaped like a bullet and a circular stainless steel with a door. Due to special design, the bullet magnet is attached to the door. By quickly releasing the buckle and opening the door, it is very easy to clean and is an effective device for removing iron containing impurities from dry powder or gravity particle material streams in pneumatic production lines. The bullet head permanent magnet has a powerful bullet shaped ferrite core. They are suitable for filtering medium to large iron containing pollutants from high-capacity crude free fall bulk streams.

Item No :

Bullet MagnetsOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysBullet Magnets are powerful magnetic separators designed for effective removal of ferrous contaminants from various materials. They feature a compact and robust design that allows them to be easily installed in pipelines or chutes.It contains three important processes:

1. Ferrous contaminants: Bullet Magnets are specifically engineered to attract and capture ferrous (iron-based) contaminants such as metal shavings, nails, screws, or other magnetic debris that may be mixed with materials being processed.

2. Magnetic separators: These devices utilize strong magnets to create a magnetic field that attracts and holds ferrous contaminants. The captured contaminants are then easily removed from the magnetic separator for disposal, ensuring clean and high-quality end products.

3. Pipeline or chute installation: Bullet Magnets are designed to be conveniently installed in pipelines or chutes, allowing for seamless integration into existing processing systems. This placement enables efficient and continuous separation of ferrous contaminants from flowing materials, minimizing production downtime and maximizing productivity.

In summary, Bullet Magnets are versatile magnetic separators that excel at removing ferrous contaminants from materials in industries such as food processing, recycling, mining, and more. Their compact design, powerful magnetic strength, and easy installation make them an excellent choice for enhancing product purity and ensuring equipment.

Specifications for regular styles:

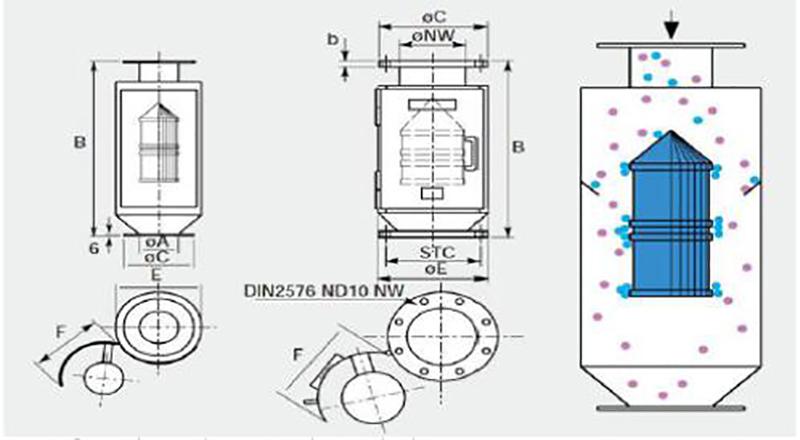

1.1Bullet Magnets--Pipeline Magnets

Left:without Flange Rigth:with Flange

|

Item no. |

A |

B |

C |

E |

F |

Capacity |

|

(t/h) |

||||||

|

BM-100 |

100 |

550 |

180 |

220 |

240 |

6 |

|

BM-150 |

150 |

600 |

230 |

275 |

310 |

20 |

|

BM-200 |

200 |

650 |

280 |

345 |

405 |

50 |

|

BM-250 |

250 |

750 |

330 |

430 |

490 |

75 |

|

BM-300 |

300 |

850 |

400 |

485 |

550 |

100 |

|

BM-400 |

400 |

950 |

500 |

620 |

665 |

150 |

|

BM-500 |

500 |

1100 |

600 |

780 |

770 |

200 |

Sanitary model of a tube magnet system with Din 2576 ND10 flqnges

|

Item no. |

NW |

B |

C |

E |

F |

Capacity |

|

(t/h) |

||||||

|

BM-100F |

100 |

578 |

220 |

220 |

240 |

6 |

|

BM-150F |

150 |

632 |

285 |

275 |

310 |

20 |

|

BM-200F |

200 |

686 |

340 |

345 |

405 |

50 |

|

BM-250F |

250 |

790 |

395 |

430 |

490 |

75 |

All dim ensions in mm

applies to dry,granular materials

Features:

1. The bullet cone design of the magnetic core ensures the optimal contact between the magnetic field and the material flow.

2. Core magnetic field 3000GS-15000Gs optional, to ensure that iron impurities can be firmly adsorbed until they are removed.

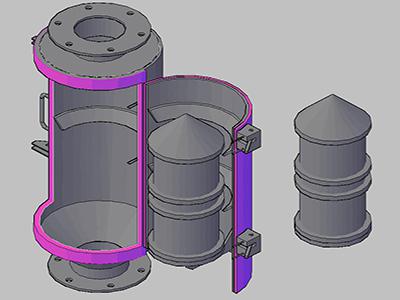

3. The cleaning process is simple and convenient - loosen the lock, open the door with the magnetic core, and scrub it clean.

4. Special requirements, can be customized.

Cooperative customer case:

Package: by wood case:

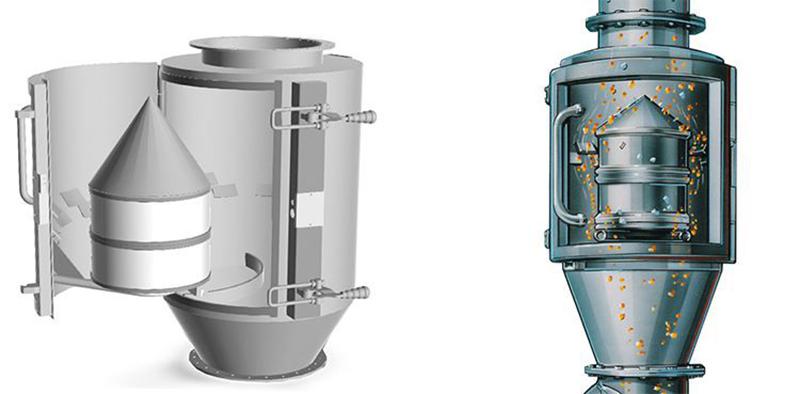

How does magnetic core filtration work?

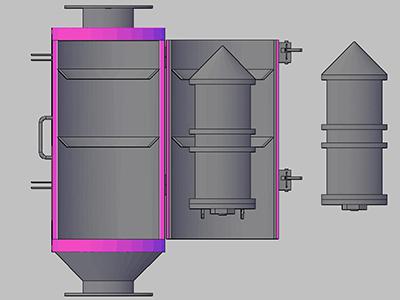

Due to the magnetic core being located in the middle of the product flow, the bullet head magnet has a very high separation yield. The circular shape of the casing and magnetic core (with a 60 ° apex) ensures continuous flow and good distribution of product flow. Then, the product redirects any product near the outer wall to the magnetic core through three powerful magnetic fields and guiding belts.

Magnet attracts passing iron particles. The captured particles adhere to one of the three magnetic poles, while the purified product flows further.

How to do cleaning?

Our product's easy to clean design makes the cleaning magnetic cone lightweight and easy to lift. The magnetic cone is fixed on the door, and when you open the door, the magnetic cone is released simultaneously. To clean the cone, simply wipe it with gloves or a cloth. This ensures that your magnetic system remains in optimal working condition and maintains its effectiveness.

Application:

Filtering iron contamination out of high-capacity coarse product streams

For filtering ferrous contaminants – such as iron and steel – out of granulates, fibers and coarser materials in high-capacity non-pressurized pipelines.

Bullet magnets are used in the bulk, animal feed, plastics, ceramics and recycling industries, among others.

Tags :