-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

LSC-X11 Powerful Electromagnetic Chuck for Surface Grinder

Ordinary rectangular electromagnetic chuck is mainly used for the magnetic table of the flat table surface grinder.

The electromagnetic chuck is mainly used for grinding the magnetic conductive workpiece with medium strength.

It has good positioning function for some workpieces that are not easy to clamp. The upper plane of the ordinary

rectangular electromagnetic chuck and the joint surface of the workpiece should be smooth, so that the workpiece

can be firmly absorbed and the grinding process can be ensured. Apply to lamping difficult workpiece, make the

machining process safety, convenient, efficient.

Item No :

LSC-X11Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysLSC-X11 Powerful Electromagnetic Chuck for Surface Grinder

The X11 Powerful Electromagnetic Chuck for Surface Grinder is a remarkable tool that combines strength, precision, and versatility. Designed for surface grinding applications, this chuck harnesses the power of electromagnetism to securely hold workpieces in place during machining operations. The circular design ensures uniform and efficient magnetic force distribution across its surface, providing enhanced stability and accuracy. With its permanent magnet technology, the X11 chuck offers reliable holding power without the need for external power supply, making it a convenient and cost-effective solution for various industrial settings. Its robust construction and rugged durability guarantee long-term performance, while its compatibility with different surface grinders allows for seamless integration into existing setups. Experience the optimal combination of power, reliability, and efficiency with the X11 Powerful Electromagnetic Chuck for Surface.

Powerful Electromagnetic Chuck for Surface Grinder Performance:

Rectangular standard electromagnetic chuck is used to hold magnetic conductive material for medium strength

grinding, Clamping force (≥ 100N/cm2). Brass-welded face plate absolutely free from gap. High rigidity, stable

accuracy and very small thermal variables. Unique coil design, very uniform suction.

All of the forms are available in a regular format, please consult them in detail.

Special specification can be customized according to customer's requirement.

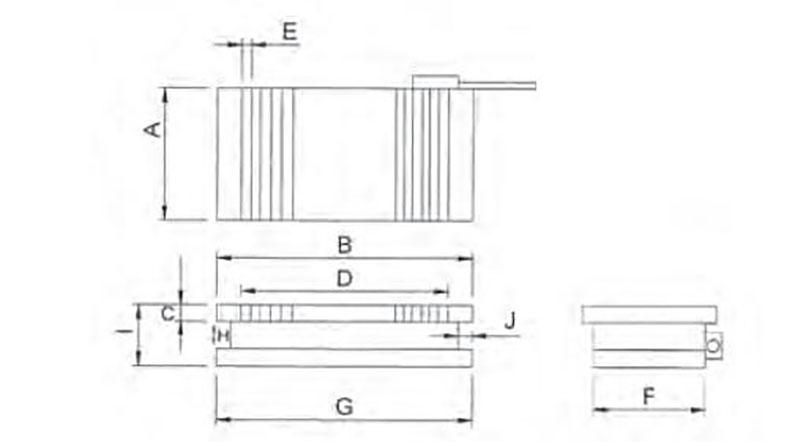

Grinder Electromagnetic Chuck Specifications:

|

Model |

Dimension(mm) |

N.W |

DCV |

A |

||||||||

|

A |

B |

C |

D |

E |

F |

G |

I |

J |

(KG) |

|

|

|

|

LSC11 200X630 |

200 |

630 |

30 |

550 |

22(4+18) |

192 |

20 |

100 |

30 |

18.5 |

110 |

1 |

|

LSC11 250X500 |

250 |

500 |

30 |

400 |

22(4+18) |

244 |

20 |

95 |

30 |

25 |

110 |

1 |

|

LSC11 300X600 |

300 |

600 |

30 |

510 |

22(4+18) |

285 |

20 |

88 |

30 |

21 |

110 |

1.1 |

|

LSC11 300X680 |

300 |

680 |

30 |

600 |

22(4+18) |

296 |

20 |

116 |

30 |

31 |

110 |

1.36 |

|

LSC11 300X800 |

300 |

800 |

30 |

730 |

22(4+18) |

296 |

20 |

116 |

12 |

41 |

110 |

1.8 |

|

LSC11 300X1000 |

300 |

1000 |

30 |

900 |

22(4+18) |

294 |

20 |

110 |

12 |

51 |

110 |

2 |

|

LSC11 320X800 |

320 |

800 |

30 |

704 |

22(4+18) |

314 |

20 |

100 |

12 |

61 |

110 |

1.46 |

|

LSC11 320X1000 |

320 |

1000 |

30 |

900 |

22(4+18) |

314 |

20 |

110 |

12 |

71 |

110 |

2 |

|

LSC11 400X800 |

400 |

800 |

30 |

704 |

22(4+18) |

392 |

20 |

105 |

10 |

81 |

110 |

1.45 |

|

LSC11 400X1000 |

400 |

1000 |

30 |

904 |

22(4+18) |

392 |

20 |

105 |

10 |

91 |

110 |

1.9 |

|

LSC11 500X1000 |

500 |

1000 |

30 |

858 |

22(4+18) |

492 |

20 |

105 |

10 |

101 |

110 |

2 |

|

LSC11 600X1000 |

600 |

1000 |

30 |

858 |

22(4+18) |

592 |

20 |

107 |

10 |

101 |

110 |

2.4 |

|

LSC11 800X1000 |

800 |

1000 |

30 |

858 |

22(4+18) |

795 |

20 |

115 |

15 |

101 |

110 |

3.2 |

|

LSC11 500X1500 |

500 |

1500 |

30 |

1372 |

22(4+18) |

492 |

20 |

112 |

15 |

101 |

110 |

5 |

Technology of Powerful Electromagnetic Chuck For Surface Grinder:

The coil windings should be arranged neatly, evenly and tightly, the outside of the coil should be tied firmly, the coil should be vacuum dipped and dried, and insulating materials should be used to reliably seal it in the suction cup; the lead wire of the suction cup should be good Sealing, insulation and anti-breakage measures are adopted, and the lead wire connectors have good anti-falling measures

.

Application of Electromagnetic Chuck For Surface Grinder:

Packing of Electromagnetic Chuck For Surface Grinder:

Tags :