-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

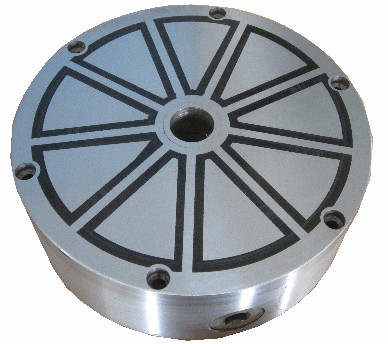

LSC-X51 Radiated circular permanent magnet chuck

Application of Radiated circular permanent magnet chuck:

Suitable for small vertical surface grinder, cylindrical grinder, internal grinder Mild cutting grinding, lathe. The whole panel structure Keep the disk with high precision, small change, the suction of up to 180N/cm.

Item No :

LSC-X51Order(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysLSC-X51 Radiated circular permanent magnet chuck

The X51 Radiated circular permanent magnet chuck is an innovative magnetic chuck designed for efficient and precise workholding. Its key features include radiated magnetic fields, circular shape, and permanent magnet technology.

The radiated magnetic fields of the X51 chuck ensure uniform magnetic distribution across the entire circular surface. This allows for enhanced holding power and stability, making it suitable for various machining applications. The circular shape of the chuck provides a centered holding area, allowing for easy alignment of workpieces and reducing setup time. Its permanent magnet technology ensures consistent magnetic force without the need for external power sources, enhancing convenience and versatility.

Product features:

(1) It can be installed in a rotary grinder.

(2) It is suitable for precision grinding of smaller and thinner workpieces.

(3) Low residual magnetism.

(4) It can improve the grinding of thin workpieces.

(5) Adjust the magnetic force appropriately.

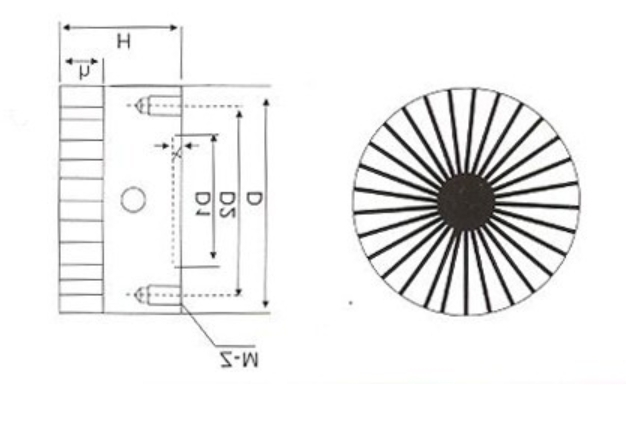

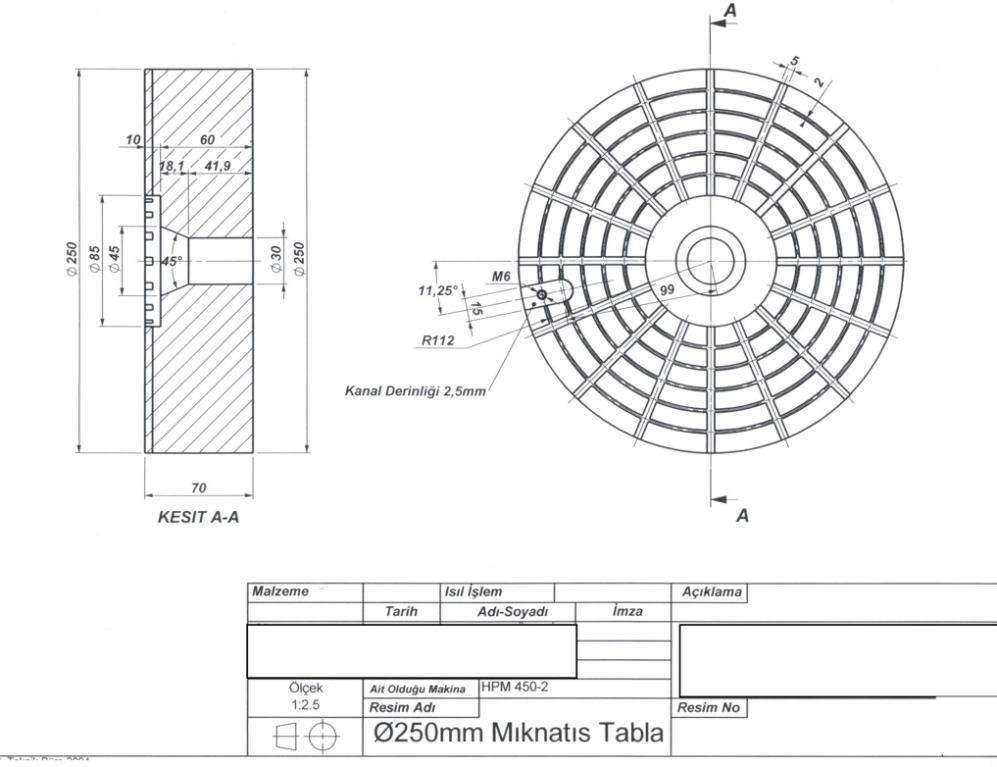

Radiated circular permanent magnet chuck Schematic diagram:

Radiated circular permanent magnet chuck

Schematic diagram of radiant pole circular permanent magnet chuck

Suggestions for use: There are two ways of installation (through hole/block).

Please choose product’s according to the way of installation.

More specifications can be customized.

All of the forms are available in a regular format, please consult them in detail.

Product Specification:

|

Model |

Size |

|

N.W(kg) |

|||||||

|

D |

H |

h |

D1 |

D2 |

K |

Z |

M |

Radiant pole |

||

|

X51 200 |

200 |

76 |

18 |

160H7 |

180 |

4 |

4 |

M10 |

18 |

|

|

X51 250 |

250 |

76 |

18 |

200H7 |

224 |

4 |

4 |

M10 |

28 |

|

|

X51 300 |

300 |

76 |

18 |

230H7 |

260 |

4 |

4 |

M10 |

35 |

|

|

X51 350 |

350 |

76 |

18 |

280 |

315 |

4 |

4 |

M12 |

45 |

|

|

X51 400 |

400 |

76 |

18 |

300 |

370 |

4 |

4 |

M12 |

60 |

|

|

XF51 450 |

450 |

76 |

18 |

365 |

450 |

6 |

6 |

M12 |

75 |

|

|

XF51 500 |

500 |

76 |

18 |

430 |

520 |

6 |

6 |

M12 |

105 |

|

Method of using radiated circular permanent magnet chuck:

1. Place the workpiece on the working table of the sucker, then insert the wrench into the hole of the shaft and rotate 180 to ON clockwise, so that the workpiece can be absorbed for processing.

2. After the workpiece is processed, the wrench is inserted into the shaft hole and rotated counterclockwise 180 to OFF to remove the workpiece.

Maintenance and maintenance of Radiated circular permanent magnet chuck:

1. Before using the sucker, the surface should be cleaned to avoid scratching affecting the accuracy.

2. Use the ambient temperature at - 40C - 50C. Strike is strictly prohibited to prevent magnetic force from decreasing.

3. Coat the working face with anti-rust oil after use to prevent rust.

Packing:

Cooperative customer case:

Tags :