-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

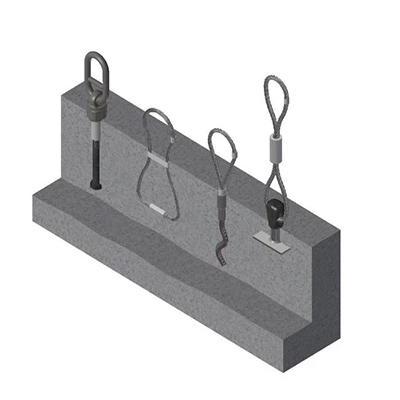

Wavy Tail Anchor (Long Type) is a mechanical anchor designed for precast concrete components. Its tail adopts a unique wavy structure, which can greatly improve the bonding strength and pull-out resistance with concrete. This product is widely used in prefabricated buildings, bridges, tunnels and other projects to ensure a stable connection between components and enhance the safety and durability of the overall structure.

The socket of the Wavy Tail is available in high grade zinc plated carbon steel and is swaged to a waved reinforcment bar. They are available with Rd12 to Rd52 threads that have load ratings from 500kg to 12,500kg. Stainless Steel sockets and re-bar tails are available to special order.

Item No :

Wavy Tail Anchor(Long Type)Order(MOQ) :

500Product Origin :

chinaLead Time :

7-10daysWavy Tail Anchor (Long Type)

Wavy Tail Anchor (Long Type) is an innovative mechanical anchor designed for modern precast concrete structures. Its unique wavy tail structure significantly improves the overall performance of the anchoring system by optimizing mechanical distribution, making it an indispensable key connector in prefabricated buildings.

The socket of the Wavy Tail is available in high grade zinc plated carbon steel and is swaged to a waved reinforcment bar. They are available with Rd12 to Rd52 threads that have load ratings from 500kg to 12,500kg. Stainless Steel sockets and re-bar tails are available to special order.

The Long Wavy Tail Anchor for Precast Concrete in Wavy Tail Anchor (Long Type) is a special anchoring device designed for precast concrete components. Its core feature is the extended wavy tail structure, which is used to enhance the bonding strength with concrete and the mechanical anchoring performance.

| Code | Size | S.W.L | Dimensions(MM) |

|

|||

| KGS | L | D | d | e | |||

| LSC 330212137 | Rd12 | 500 | 137 | 16 | 8 | 22 | |

| LSC 330216216 | Rd16 | 1200 | 216 | 21 | 12 | 27 | |

| LSC 330220257 | Rd20 | 2000 | 257 | 27 | 14 | 35 | |

| LSC 330224350 | Rd24 | 2500 | 350 | 31 | 16 | 43 | |

| LSC 330230450 | Rd30 | 4000 | 450 | 40 | 20 | 56 | |

| LSC 330236570 | Rd36 | 6300 | 570 | 48 | 25 | 69 | |

| LSC 330242620 | Rd42 | 8000 | 620 | 54 | 28 | 80 | |

| LSC 330252880 | Rd52 | 12500 | 880 | 68 | 32 | 95 | |

Wavy Tail Anchor (Long Type) is usually made of high-strength carbon steel (such as 45 steel, Q355B) or stainless steel (such as 304, 316) to ensure its excellent mechanical properties and durability. Of course, the specific material selection depends on the project requirements and environmental conditions:

| Environmental conditions | Recommended materials | Features |

| Ordinary buildings, bridges | Galvanized carbon steel (Q355B) | Economical, durable and rust-proof |

| Wet, coastal areas | 316 Stainless Steel | Anti-chloride ion corrosion, super long service life |

| Chemical plants, highly corrosive environments | 304/316 stainless steel | Acid and alkali resistant, chemical corrosion resistant |

Innovative structural design

Wave-shaped tail structure increases the contact area with concrete by more than 30%

Progressive bite structure achieves uniform stress distribution

Extended design, suitable for thicker concrete components

Excellent performance

Tensile strength: up to 600MPa

Shear resistance: 40% higher than traditional anchor bolts

Fatigue life: passed 1 million cycles of load test

Selection of high-quality materials

Basic model: Q355B carbon steel + hot-dip galvanizing (zinc layer thickness ≥80μm)

High-end model: 316L stainless steel (suitable for harsh environments such as marine engineering)

Special model: customizable epoxy coating or Dacromet treatment

Technical advantages

Dynamic bearing capacity: meets the requirements of 8-degree earthquake fortification

Anti-slip performance: tested displacement <0.1mm

Corrosion resistance level: no red rust after 2000 hours of salt spray test

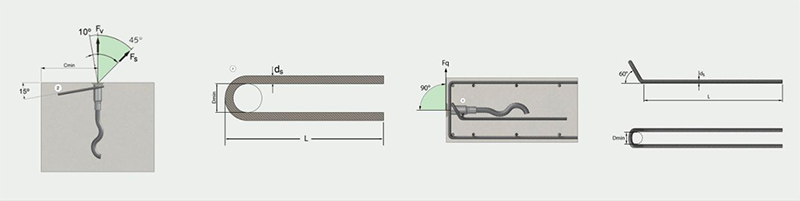

Construction tolerance: ±5° angle deviation is allowed

Advantages compared to traditional anchors

| characteristic | Long wave tail anchor | Traditional straight rod anchor |

| Pull-out strength | Higher (wavy shape + long tail to enhance grip) | Reliance on gluing or mechanical expansion |

| Stress distribution | More uniformity, less concrete cracking | Prone to local stress concentration |

| Construction efficiency | Pre-buried and prefabricated, no need for on-site treatment | Drilling or post-installation may be required |

| Durability | Anti-rust design, long life | Depends on the quality of protective coatings |

Reinforcement requirements

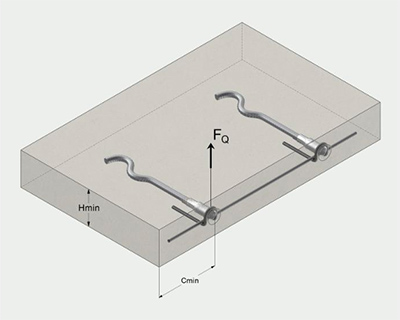

Shear reinforcement notes

Where the unit is being tilted, or the lift is in the edge of the element resulting in a shear pull on the socket, the reinforcement shown here must be used. This reinforcing bar should touch the socket where it wraps around and be located as close to the concrete surface as cover allows. Anchorage reinforcement bar can be removed if shear reinforcement can be wrapped around the cage.

Application scenarios

- Prefabricated buildings: used for the connection of prefabricated components such as wall panels, floor slabs, beams and columns.

- Bridge engineering: Strengthen bridge panels, guardrails and other parts to improve the overall bearing capacity.

- Underground engineering: suitable for structures that require high pull-out resistance, such as tunnel segments and subway stations.

Why choose Wavy Tail Anchor (Long Type)?

Under the modern construction requirements of fast construction and high safety, traditional anchor bolts may not meet the mechanical requirements of prefabricated components. However, Wavy Tail Anchor, with its wave tail design, provides stronger grip and pull-out resistance, becoming the preferred solution for engineers in earthquake, wind and impact resistance projects.

Why Choose Us

(1) More than 15 years of experience in manufacturing and trading precast concrete systems.

(2) Comply with strict technical requirements and meet the market's demand for human safety. (Precast concrete elements may be lifted several times after pouring and during storage and installation - by using this system, designers and workers managers can ensure that each lift is done safely and quickly. Without a designed and coordinated system, may result in material breakage at some point during production/delivery.

(3)LSC's products are enhanced through factory quality control inspections during production. Each order can be tension tested if necessary.

(4)OEM/ODM capability: LSC has more than 10 years of experience in OEM/ODM products, and more than 150 cooperative factories, we can provide you with competitive prices and stable quality.

Tags :