-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

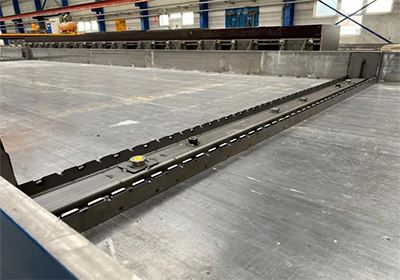

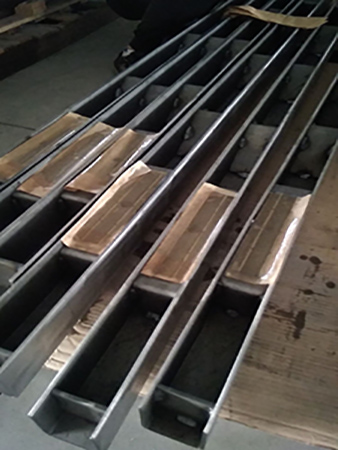

The U60 magnetic formwork system consists of a 60 mm wide U-shaped metal channel and an integrated magnetic button system. It is an efficient formwork system designed for the production of precast concrete panels and double-layer wall panels. It is made of high-strength steel and special magnetic materials, and uses magnetic adsorption to achieve rapid assembly and precise positioning of the formwork, completely subverting the cumbersome installation process of traditional formwork systems.

Item No :

U60 Magnetic Formwork System For Precast Slabs and Double Wall Panel ProductionOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10daysU60 Magnetic Formwork System For Precast Slabs and Double Wall Panel Production

Driven by the wave of building industrialization, prefabricated components have gradually become the mainstream choice of modern construction due to their advantages of high efficiency, environmental protection, and controllable quality. As a key link in the production of prefabricated components, the performance of the formwork system directly affects the quality and production efficiency of the components.

This formwork system, through the tensioning mechanism, the profile (planing layer) is pulled to the bottom of the formwork, thus managing the exact edges of the manufactured piece. Since the system is a unit, measuring errors are impossible. Simple and fast operation increases work safety. The system can be easily removed and dismantled from the bottom of the formwork using the corresponding lever.

Through the tensioning mechanism and the handle knob as well as the separate arrangement of the tensioning mechanism and the formwork, the forces acting on the formwork and magnets during the concreting process are absorbed.

The built-in tensioning element is placed in a safe position, so the formwork system is less sensitive to dirt.

To facilitate stacking and prevent the formworks from sticking to each other, the knob is made of anti-magnetic material. The system can also be delivered to storage rooms and robots.

In case of defects, the old formwork can be easily replaced by simply removing it from 3 screws. The shape and size can be reduced as required.

It is very convenient to use the concrete formwork magnets, the construction workers can build the concrete formwork on the ground and install the two hexagonal bolts with adapters to the concrete formwork. There is another way to use concrete formwork magnets, where workers can fix the concrete formwork on a hydraulic platform, build and store concrete walls, and use forklifts and cranes to move the walls when in use.

Technical parameters

Material: NdFeB magnets, carbon steel, U-shaped metal channel steel (optional steel, stainless steel or aluminum alloy).

Magnetic force: high-performance NdFeB magnets, up to 900 kg.

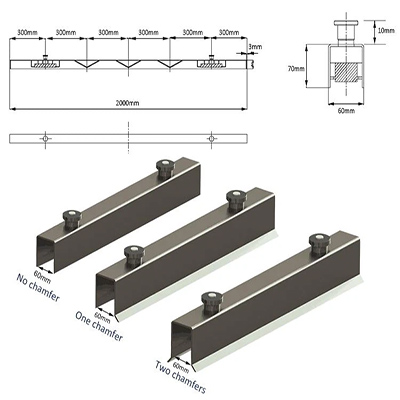

Dimensions: standard width 60 mm, height 60-80 mm, length can be customized according to requirements.

Structure: integrated magnetic tensioning mechanism to ensure that the formwork fits tightly to the casting platform.

Surface treatment: black oxidation treatment or customized according to requirements.

| Model | L(mm) | W(mm) | H(mm) | Magnet Force(kg) | Chamfer |

| U60-500 | 500 | 60 | 70 | 2 x 450KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-750 | 750 | 60 | 70 | 2 x 450KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-900 | 900 | 60 | 70 | 2 x 450KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-1000 | 1000 | 60 | 70 | 2 x 450KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-1500 | 1500 | 60 | 70 | 2 x 900KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-2000 | 2000 | 60 | 70 | 2 x 900KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-2500 | 2500 | 60 | 70 | 3 x 900KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-3000 | 3000 | 60 | 70 | 3 x 900KG Magnets | Non/1/2 Sides 10mm x 45° |

| U60-3500 | 3500 | 60 | 70 | 3 x 900KG Magnets | Non/1/2 Sides 10mm x 45° |

Key Features

1. Integrated Magnetic Mechanism

The system uses powerful permanent magnets to provide a strong and reliable holding force. For example, the U60 system has a magnetic force of up to 900 kg per magnet unit. This ensures a secure hold on the casting table during the concrete pouring process.

2. Customizable Profiles

The U profiles can be made in a variety of lengths, widths and heights to meet specific project requirements. Options include profiles with or without lateral mitering for chamfering. This flexibility allows the system to be adapted to different precast elements, such as double walls and lattice beam ceilings.

3. Automated and Manual Operation

The system is compatible with both robotic and manual operation. It can be easily positioned, connected and removed using a robot or manually. This versatility makes it suitable for both highly automated production lines and manual setups.

4. High Precision and Safety

The magnetic tension mechanism ensures that the formwork profile is tightly pulled on the casting table, resulting in precise edges and minimizing the risk of measurement errors. In addition, the system is designed to be lightweight and easy to operate, which increases work safety.

5. Durability and Maintenance

The system is built with high-performance materials such as rare earth magnets and carbon steel, ensuring durability and resistance to concrete. It also features easy maintenance and cleaning, with built-in tensioning elements placed in a safe position to avoid contamination.

The advantages of the U60 magnetic formwork system are fully reflected in the use of the precast concrete industry:

Efficient and convenient: The magnetic connection method increases the speed of formwork assembly by several times, greatly shortening the production cycle.

Precise and reliable: The built-in positioning system ensures the accurate size of the components and the stable and reliable quality.

Reduced costs: The modular design and reuse characteristics effectively reduce the cost of formwork.

Green and environmentally friendly: Reduce the use of wood and construction waste, which is in line with the concept of green building.

The following are the types and characteristics of construction projects it is suitable for:

1. Precast Floor Slabs

The magnetic formwork system is particularly suitable for the production of precast floor slabs, including complex structures such as grid beam ceilings. Its U-shaped metal channel design and built-in magnetic mechanism ensure that the formwork is accurately aligned during the pouring process to reduce errors. In addition, the system supports customization of multiple heights and lengths to meet the needs of different floor thicknesses.

2. Double Wall Panels

For the production of double wall panels, the magnetic formwork system can provide high-precision alignment and stable fixing effects. Its magnetic mechanism can pull the formwork tightly to the bottom of the pouring platform to ensure that the edges of the wall panels are flat. The system also supports multiple heights (such as 60mm, 70mm, 100mm, etc.) to meet the design requirements of different double wall panels.

3. Facade Panels and Sandwich Walls

The magnetic formwork system can be used to produce facade panels and sandwich walls. Its lightweight design and strong magnetic force (up to 900 kg) can ensure that the formwork is stably fixed during the pouring process. In addition, the system supports fast installation and removal, significantly improving production efficiency.

4. Lattice Girder Ceilings

The system is suitable for the production of lattice girder ceilings and can adapt to complex geometric shapes and size requirements. Its flexible design and strong magnetic mechanism ensure the stability and accuracy of the formwork during the pouring process.

5. Other precast components

The magnetic formwork system can also be used to produce other precast concrete components, such as solid wall panels, stair slabs, etc. Its customizability in height and length enables it to adapt to the specific needs of a variety of construction projects.

Strict packaging method

Tags :