-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic Rotary Separator consists of a cyclic magnetic bar group and housing outside. A motor is necessary to drive the magnetic rods rotating. Magnetic Rotary Separator is used to remove the ferrous contaminants from the material that is apt to caking and bridging. These materials, like power with high moisture which is certain viscous, are easy to cake using fixed magnetic separators. However, the rotary action will scatter the material and make more contaminants attracted to the rods. This unit embodies unapproachable capacity compared to other fixed separators.

Item No :

Rotary iron removerOrder(MOQ) :

1Product Origin :

chinaLead Time :

7-10daysRotary iron remover

Rotary Magnet Magnetic Separator:

Rotary magnets are designed to remove ferrous particles from product flows that tend to clog and bridge in stationary magnetic grates. The unit rotates a number of powerful magnetic tubes while the product passes through. The magnetic action attracts and holds the unwanted ferrous particles, and the rotary action prevents the product from packing the process stream. The rotary action also breaks apart lumps and cohesive materials. However, with rotary magnetic separators, the rotary action will scatter the material and make more contaminants attracted to the rods. It has been designed specifically to ensure that the product remains free-flowing, thus preventing the product from bridging or clogging, such as milk powder or starch.

Particles are as small as 30 microns can be extracted thus proving ideal for food and pharmaceutical applications.

Technical features of Rotary iron remover:

1. Quick-open design structure, easy to clean and install.

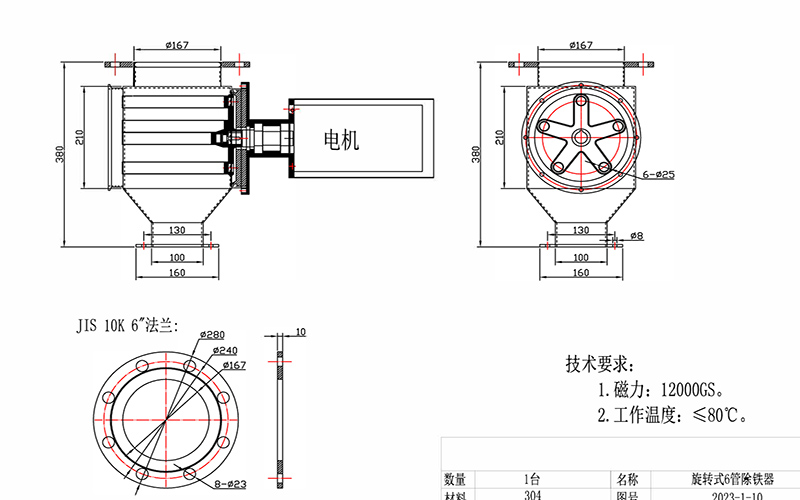

2. The maximum magnetic field can reach 12000GS, the working temperature of ordinary products is ≤80℃, and the maximum working temperature can reach 350℃ under special requirements.

3. The number of magnetic bars can be adjusted according to the characteristics of the material.

4. The inlet and outlet can be designed as flanges or square interfaces, which can be easily installed on various pipelines.

5. The rotating magnetic bar can prevent the material from agglomerating and clogging.

Specification of Rotary Magnet / Magnetic Separator:

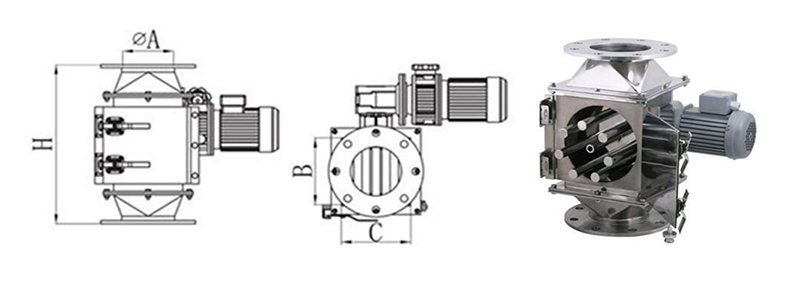

| Item | Dimension (mm) | Bar QTY | Weight (Kg) | ||||

| ΦA | B | C | H | KW | |||

| RMS150 | 150 | 205 | 208 | 450 | 0.25 | 7 | 43 |

| RMS200 | 200 | 255 | 258 | 500 | 0.25 | 9 | 54 |

| RMS250 | 250 | 305 | 308 | 550 | 0.25 | 11 | 62 |

| RMS300 | 300 | 355 | 358 | 600 | 0.37 | 13 | 72 |

| RMS350 | 350 | 405 | 408 | 650 | 0.37 | 15 | 84 |

| RMS2020 | - | 205 | 208 | 270 | 0.25 | 7 | 29 |

| RMS2525 | - | 255 | 258 | 320 | 0.25 | 9 | 38 |

| RMS3030 | - | 305 | 308 | 370 | 0.25 | 11 | 43 |

| RMS3535 | - | 355 | 358 | 420 | 0.37 | 13 | 52 |

| RMS4040 | - | 405 | 408 | 450 | 0.37 | 15 | 62.5 |

Note: We can customize according to customer requirements.

The following are designed for French customers:

Working principle:

Rotary iron remover is a magnetic filter rod (magnetic rod) made of stainless steel pipe and high B value rare earth alloy neodymium iron boron and other materials using a special manufacturing method, fixed in a frame made of stainless steel plate to form a magnetic filter. Use flange to install it in the production line conveying pipeline or at the discharge port. When the iron-containing material passes through, it is attracted by the magnetic rod and the iron-containing material is firmly adsorbed on the pipe wall to ensure the integrity of the equipment and the safety of the product.

Scope of application:

Rotary iron remover is mainly used to remove ferromagnetic impurities in powdered, flaky and granular raw materials. It is widely used in ceramics, electricity, mining, plastics, chemicals, rubber, pharmaceuticals, food, environmental protection, pigments, dyes, electronics, metallurgy and other industries.

Maintenance:

Rotary iron remover cleaning frequency: It is determined according to the content of iron impurities in the processed material, the material processing volume per hour and other parameters. Generally, the thickness of powdered iron impurities adsorbed on the surface of the magnetic bar should not exceed 10mm. Clean it regularly and timely to maintain a stable use effect.

Rotary iron remover cleaning steps: For the rotary iron remover, first turn off the power, open the iron remover door panel when the internal magnetic core stops rotating, take out the internal annular magnetic grid, and clean the iron impurities adsorbed on the surface of the magnetic bar; then install the cleaned magnetic grid in the box, fix it in place, close the door panel, and turn on the power. When cleaning the iron impurities on the surface of the magnetic bar, you can use thick cotton gloves, rags, trays and other tools. If necessary, you can wash it with water.

Precautions:

1. The iron removal chamber door must be locked before starting to prevent the raw materials from overflowing from the machine.

2. During operation, personnel should not open the machine body to avoid unnecessary injuries.

3. When cleaning the magnetic bar group, pay attention to safety and stay away from iron objects.

4. When using iron tools such as wrenches and screwdrivers for installation, be careful to stay away from the magnetic bar group.

5. There is a strong magnetic field near the iron remover. Instruments and meters should not be placed around it. Workers should not approach with sharp iron objects to prevent injuries.

6. People wearing pacemakers are prohibited from approaching within 2 meters.

Tags :