-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Revolutionizing Construction: The Lifting System for Precast Concrete Units

Feb 27, 2025The Lifting System for Precast Concrete Units

The construction industry continues to evolve, incorporating innovative technologies to improve efficiency, safety, and precision. Among these advancements, lifting systems for precast concrete units stand out as a game-changer, revolutionizing the way we handle and install precast concrete elements. As construction practices continue to evolve, lifting systems will undoubtedly play an important role.

First, demystifying the lifting system: the key components and what they do

The lifting system for precast concrete units is an elaborate assembly designed to safely and efficiently lift, manipulate, and position precast concrete elements during construction. Let’s break down its basic components and their functions:

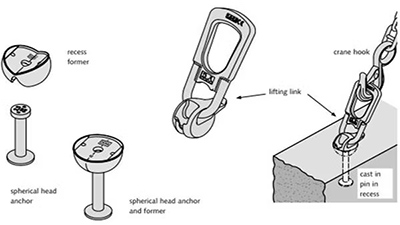

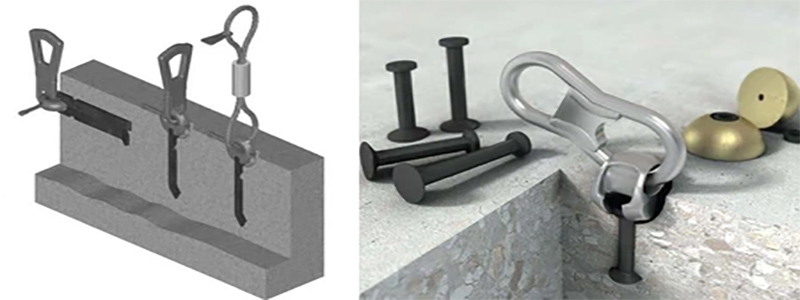

Lifting anchors: These are the workhorses of the system and are embedded into the precast concrete units when they are cast. They provide a secure connection point for the lifting equipment, ensuring a reliable connection between the unit and the lifting mechanism. There are several types of lifting anchors, including ring anchors, threaded inserts, and lifting plates, each of which is suitable for specific load capacities and concrete element configurations.

Lifting equipment: This category includes the machinery responsible for the actual lifting and moving of the precast units. Common examples include:

Crane: Tower cranes, mobile cranes, and overhead cranes are widely used for their versatility and ability to handle heavy loads at different heights and distances.

Vacuum lifters: They utilize suction cups to create a vacuum seal on the concrete surface, providing a non-intrusive lifting solution for fine or polished finishes.

Paver beams: These horizontal beams distribute the lifting load evenly across multiple lifting points, preventing stress concentrations and ensuring stability of the precast unit during lifting.

Rigging accessories: This includes a range of components that connect the lifting anchor to the lifting equipment, such as:

Slings: Slings are made of wire rope, chain or synthetic materials and provide flexibility and adjustability in lifting configurations.

Shackles: These U-shaped connectors secure the slings to the lifting anchors and other rigging components.

Turnbuckles: Used to adjust the length and tension of the slings, ensuring load distribution and alignment during lifting.

Secondly, the adoption of lifting systems for precast concrete units has brought a paradigm shift to the concrete industry, bringing multiple benefits:

Enhanced safety: By providing a safe and controllable lifting mechanism, these systems significantly reduce the risk of accidents and injuries associated with manually handling heavy precast elements.

Increased efficiency: The streamlined lifting process minimizes downtime and maximizes productivity on the construction site, thereby reducing project completion time.

Increased precision: The ability to precisely position precast units ensures accurate alignment and minimizes the need for expensive adjustments or rework.

Expanded design possibilities: Lifting systems enable the use of larger and more complex precast elements, opening up new avenues for architectural creativity and innovation.

Reduced labor costs: Automation and mechanization of the lifting process reduces reliance on manual labor, resulting in significant cost savings.

The world of applications: where lifting systems shine

The versatility of precast concrete unit lifting systems makes them an integral part of a wide range of construction projects:

High-rise buildings: Facilitates the efficient installation of precast wall panels, columns, beams and floor slabs in high-rise buildings.

Bridges and infrastructure: Enables precise placement of precast beams, abutments and other structural components in bridge construction and infrastructure projects.

Industrial facilities: Supports the construction of warehouses, factories and other industrial buildings with precast concrete elements.

Residential buildings: Simplifies the installation of precast walls, floors and stairs in residential buildings, from single-family homes to apartment complexes.

Tags :