-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

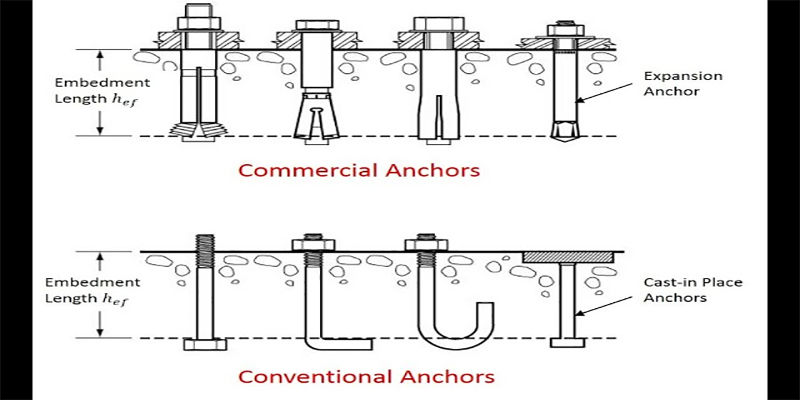

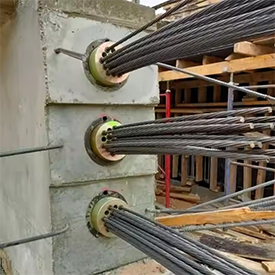

The Prestressed anchor wedges are critical components of prestressed anchorage systems, designed to secure prestressed steel bars or strands. They typically consist of an external steel barrel and internal wedge assemblies, which may be two- or three-piece configurations. These wedge assemblies ensure a secure fit with the anchored steel bar or strand through frictional engagement. The wedges are composed of wedge-shaped parts that anchor the steel by means of friction between the wedge structure and the surrounding medium, such as concrete or rock.

Item No :

Prestressed anchor wedgesOrder(MOQ) :

1Product Origin :

ChinaLead Time :

7-10daysPrestressed Anchor Wedge

The prestressed anchor comprises 4 parts, anchor ring, clip, backing plate, and spiral reinforcement. It is suitable for anchors used for prestressing concrete in engineering construction. Generally used in bridge construction, pre-installed and positioned, and then poured concrete, buried at both ends of the concrete, that is, the two ends of the bellows, which are the end faces set for the stability of the jack during tensioning.

The working principle of Prestressed anchor wedges is prestressed anchorage construction, after the steel bar or strand is tensioned to the designed prestress level, the tension force is transferred from the anchor head to the wedge. Under tensile load, the wedge is further embedded into the steel drum, utilizing the friction between the wedge and the drum to lock the steel bar or strand in place. This frictional locking mechanism effectively transfers prestress to the anchored structure, improving its stability and load-bearing capacity.

How to use Prestressed anchor wedges?

First, the prestressed steel bundle is threaded through the reserved hole in the concrete member and secured using the anchoring wedge. By applying force, the wedge is pushed into the hole, creating high friction between it and the steel bundle. This high-friction interface ensures the steel bundles are firmly anchored within the concrete structure, establishing pre-stress.

Technical Requirements and Safety Standards:

The design and application of prestressed anchor wedges must comply with specific technical requirements and safety standards. During installation, precise control over wedge positioning and anchoring force is essential to ensure correct anchoring of the prestressed steel bundles within the concrete structure. Regular inspection and maintenance of the anchoring system are necessary to guarantee long-term reliability and safety.

Prestressed Anchor Wedge Parameter

| Model | Anchor Head | Anchor Plate | Corrugated Pipe I.D. | Spiral Reinforcement/Bar | Matched Tension Jack Model | |||||

| ØD | B | A | L | ØC | ØG | H | Ød | n | ||

| LSC15(13)-1 | 48 | 50 | 90 | 35 | 80(85) | 30(35) | 6 | 4(4) | QYC270 | |

| (40) | (50) | (90) | (35) | |||||||

| LSC15(13)-2 | 94 | 50 | 135 | 110 | 45(40) | 120(110) | 40(50) | 8(8) | 3(3) | YDC650 |

| (80) | (50) | (120) | (110) | (YDC650) | ||||||

| LSC15(13)-3 | 94 | 50 | 135 | 110 | 50(50) | 130(130) | 50(50) | 10(8) | 4(3) | YDC1000 |

| (80) | (40) | (120) | (120) | (YDC650) | ||||||

| LSC15(13)-4 | 98 | 50 | 150 | 120 | 50(50) | 150(150) | 50(50) | 14 | 4(4) | YDC1500 |

| (85) | (50) | (135) | (120) | (10) | (YDC650) | |||||

| LSC15(13)-5 | 108 | 50 | 180 | 130 | 55(50) | 170(160) | 50(50) | 14 | 4(4) | YDC1500 |

| (94) | (55) | (150) | (120) | (14) | (YDC1500) | |||||

| LSC15(13)-6,7 | 127(108) | 50 | 190 | 160 | 70(60) | 200(190) | 50(50) | 14 | 4(5) | YDC2000 |

| (55) | (165) | (150) | (14) | (YDC1500) | ||||||

| LSC15-8 | 137 | 60 | 230 | 180 | 80 | 240 | 60 | 16 | 5 | YDC2000 |

| LSC15(13)-9 | 154 | 60 | 240 | 190 | 80(60) | 240(220) | 60(50) | 16 | 5(5) | YDC2500 |

| (128) | (60) | (180) | (160) | (16) | (YDC1500) | |||||

| LSC15(13)-10 | 167 | 60 | 250 | 210 | 80 | 270 | 60 | 16 | 6 | YDC2500 |

| LSC15(13)-11/12 | 167 | 60 | 260 | 210 | 90(80) | 270(240) | 60(60) | 16 | 6(5) | YDC3000 |

| (148) | (60) | (215) | (190) | (16) | (YDC2000) | |||||

| LSC15-14/15 | 187 | 65 | 270 | 220 | 90 | 310 | 60 | 18 | 6 | YDC3500 |

| LSC15-16 | 207 | 65 | 290 | 250 | 90 | 330 | 60 | 18 | 6 | YDC4000 |

| LSC15(13)-19 | 207 | 70 | 310 | 265 | 100(90) | 350(310) | 60(60) | 18 | 7(6) | YDC5000 |

| (178) | (65) | (270) | (260) | (18) | (YDC3000) | |||||

| LSC15(13)-22 | 227 | 70 | 380 | 265 | 120(100) | 380(330) | 60(60) | 20 | 7(6) | YDC5000 |

| (188) | (65) | (290) | (260) | (18) | (YDC3000) | |||||

| LSC15(13)-24 | 237 | 75 | 380 | 380 | 120(100) | 380(340) | 60(60) | 20 | 7(6) | YDC6500 |

| (208) | (75) | (300) | (270) | (18) | (YDC4600) | |||||

| LSC15(13)-25,27 | 247 | 90 | 380 | 300 | 120(100) | 400(360) | 60(60) | 20 | 7(6) | YDC6500 |

| (208) | (80) | (320) | (280) | (18) | (YDC4600) | |||||

| LSC15(13)-31 | 277 | 90 | 390 | 355 | 130(105) | 450(380) | 70(60) | 22 | 8(6) | YDC6500 |

| (238) | (90) | (340) | (320) | (20) | (YDC4600) | |||||

| LSC15(13)-37 | 287 | 100 | 430 | 435 | 140(120) | 500(430) | 70(70) | 22 | 8(6) | YDC8000 |

| (238) | (100) | (370) | (370) | (22) | (YDC6500) | |||||

| LSC15(13)-42 | 268 | 100 | 395 | 380 | 130 | 450 | 70 | 22 | 7 | YDC10000 |

| LSC15(13)-44 | 327 | 110 | 460 | 465 | 160 | 550 | 70 | 22 | 8 | YDC10000 |

| LSC15(13)-55 | 360 | 120 | 530 | 515 | 160(140) | 630(510) | 70(70) | 25 | 9(7) | YDC12000 |

| (298) | (110) | (460) | (460) | (22) | (YDC10000) | |||||

Features:

1. Structural Stability: Prestressed anchor wedges ensure reliable transfer of prestress to the concrete structure by securely fixing the end of the steel bundle or strand.

2. High Load-Bearing Capacity: These wedges can withstand significant prestress, making them suitable for various high-load anchorage projects.

3. Simple and Reliable Design: The design is straightforward, easy to install, and highly reliable, maintaining effective anchoring performance over extended periods.

4. Adjustable Performance: Prestressed anchor wedges often feature adjustable functions, allowing prestress adjustment according to project needs.

5. Economical and Efficient: Their use improves structural mechanical performance, reduces stress in concrete structures, extends service life, and reduces material usage, thus saving costs.

Application Areas

1. Architectural Engineering: Prestressed anchor wedges are widely used in reinforcing and stabilizing high-rise buildings, bridges, tunnels, and other structures. For example, in foundation reinforcement of high-rise buildings, they enhance bearing capacity and stability.

2. Municipal Engineering: In railway, highway, subway, and other municipal projects, they are used for slope support and subgrade reinforcement to ensure project safety and stability.

3. Hydraulic Engineering: In dam and reservoir projects, they are used for dam reinforcement and foundation stabilization to prevent sliding and leakage.

4. Mine Engineering: In mine support, they strengthen roadways and goafs to improve mine safety.

Why Choose Us?

1.Asian reliable supplier from China, we have served numerous clients all over the world. We have been working with our customers for fifteen years. We have a comprehensive set of services, sales, and after-sales service.

2.We have all the popular design; Small order is accepted and competitive price.

3.Our team will inspect and test goods very carefully when Know the material tread and know the market

4.All inquiries responded within 12 hours Close to the port, providing great advantages to trade

5.What are your payment terms? For other payment terms, we can negotiate about it depend on specific order details.

6.After the product enters the freight forwarding warehouse:

①Our salesman confirms that the bill of lading is correct and informs the customer of the sailing date and arrival date.

②Provide customs clearance information such as invoices, packing data, BL, Form-e and CO, pictures of products entering the warehouse, etc.

③Or provides a one-stop DDP service for customs clearance.

Tags :