-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Magnetic Separators are devices that use magnetic fields to separate magnetic and non-magnetic materials. They are widely used in the industrial field, mainly for the separation, purification and recovery of materials. In modern industry, magnetic separators play a vital role.

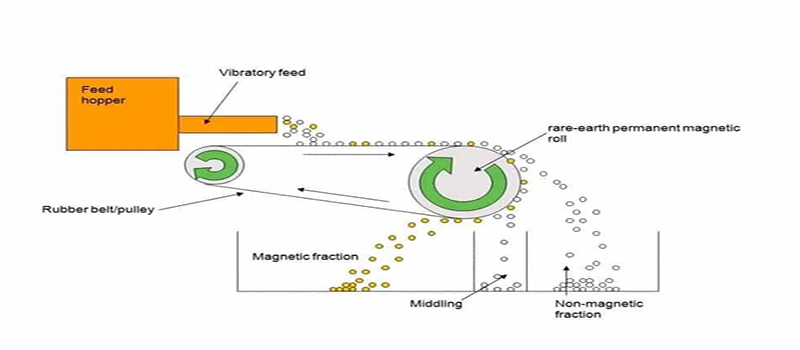

Working Principle

The core of the magnetic separator is its magnetic field system. It separates magnetic materials from non-magnetic materials (such as quartz, bauxite, etc.) by generating a strong magnetic field to attract magnetic materials (such as iron, magnetite, etc.). According to the strength and distribution of the magnetic field, magnetic separators can be divided into different types to meet different separation needs.

Magnetic field type: The magnetic field of the magnetic separator can be a permanent magnetic field (using permanent magnets such as neodymium iron boron) or an electromagnetic magnetic field (generating a magnetic field through electric current). Permanent magnetic separators are usually used in scenarios with fixed magnetic field strength, while electromagnetic magnetic separators can change the magnetic field strength by adjusting the current, which is suitable for applications that require flexible adjustment of the magnetic field.

Magnetic field distribution: The magnetic field can be uniformly distributed or gradient distributed. Gradient magnetic fields are more suitable for separating fine magnetic particles because they can be captured more effectively in places where the magnetic field strength changes.

Magnetic separators can be divided into many types according to their working principles and application requirements.

1. Permanent magnetic separator: The magnetic field generated by permanent magnets is used for separation. This type of magnetic separator has a simple structure and low maintenance cost, and is suitable for processing large amounts of materials.

2. Electromagnetic magnetic separator: The magnetic field is generated by electromagnets, and the magnetic field strength is adjustable, which is suitable for occasions requiring high-precision separation.

3. High-gradient magnetic separator: The high-gradient magnetic field can effectively separate weakly magnetic materials and is often used in mineral processing and wastewater treatment.

4. Drum magnetic separator: The material passes through the rotating drum, the magnetic material is adsorbed on the surface of the drum, and the non-magnetic material is discharged. Suitable for continuous production occasions.

5. Pipeline magnetic separator: Installed in the pipeline, it is used to remove magnetic impurities in the fluid and is widely used in the food, chemical and pharmaceutical industries.

The advantages and limitations of magnetic separators are mainly as follows:

Advantages:

Efficient separation: It can quickly and effectively separate magnetic and non-magnetic materials.

Simple operation: Most magnetic separators have simple structures, easy operation and low maintenance costs.

Environmental protection and energy saving: In many cases, magnetic separators can reduce dependence on chemical reagents and reduce energy consumption.

Limitations:

Ineffective for non-magnetic materials: Magnetic separators can only separate magnetic materials, but are powerless for the separation of non-magnetic materials.

Limited magnetic field strength: For some weakly magnetic materials, a higher magnetic field strength may be required to achieve effective separation, which may increase equipment costs and energy consumption.

The application range of magnetic separators is very wide. The following are some of the main application scenarios:

1. Mining: In the process of ore processing, magnetic separators are used to separate magnetic minerals (such as magnetite) and non-magnetic minerals to improve the grade of ore.

2. Recycling industry: In waste treatment, magnetic separators are used to separate metal waste, such as steel, aluminum, etc., to achieve resource recycling.

3. Food industry: Used to remove metal impurities in food raw materials to ensure food safety.

4. Chemical and pharmaceutical: In the process of chemical and pharmaceutical, magnetic separators are used to remove magnetic impurities in raw materials to ensure product quality.

5. Wastewater treatment: In sewage treatment plants, magnetic separators are used to remove magnetic particles in wastewater to reduce environmental pollution.