-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

What are embedded anchor plate magnets?

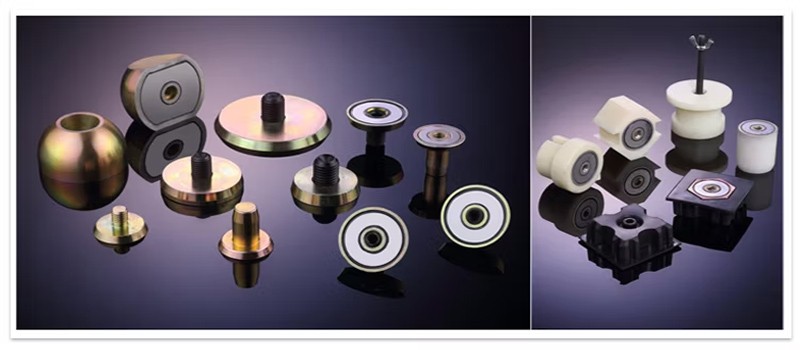

Mar 30, 2025An embedded anchor plate magnet is a fixing device that embeds a high-strength permanent magnet into a metal or composite anchor plate. It uses magnetic force to achieve rapid adsorption and fixation, while ensuring long-term stability through the anchor plate, and is suitable for scenarios that require frequent disassembly or adjustment.

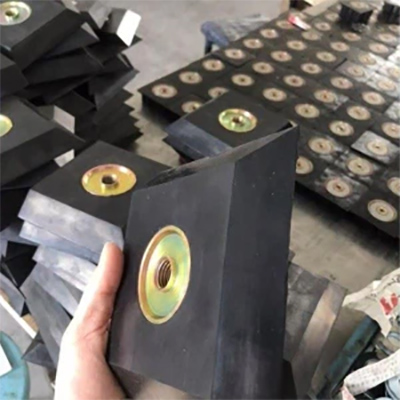

During the production of precast concrete components, some steel anchor plates need to be fixed in precast concrete walls. This magnetic product is specially developed and produced for fixing anchor plates.

This embedded magnet for precast concrete plate anchoring consists of rubber, iron and magnets. The product is magnetized on both sides, one side is fixed to the designated position of the workbench, and the other side is fixed with an anchor plate. The high holding force of the magnet ensures that the iron plate will not slip and slide during the production of the component. The crushed stone component can be customized to any size to fit most sizes of anchor plates. This makes the production of components more precise and reduces the defective rate.

Core Features

✅ Super strong magnetic force - using high-performance neodymium magnets (NdFeB) to provide strong adsorption force to ensure a firm fixation.

✅ Durable structure - the anchor plate is made of stainless steel or galvanized steel, which is corrosion-resistant and wear-resistant and suitable for various harsh environments.

✅ Flexible installation - can be embedded, welded or bolted to adapt to different application scenarios.

✅ Quick disassembly - magnetic design, easy to adjust and maintain, improve work efficiency.

✅ Widely applicable - suitable for machinery manufacturing, construction, automation equipment, logistics warehousing and other fields.

Installation and use of magnets for precast concrete anchor plates

Positioning anchor plates: Place anchor plates at designated locations on precast concrete walls, usually at the edge of the wall or at locations where connections are required.

Placing magnets: Place embedded anchor plate magnets on the precast concrete platform below the anchor plate so that the magnetic surface of the magnet is in close contact with the anchor plate.

Securing anchor plates: Press the switch button of the magnet (if it is a switchable magnet) to activate the magnetism of the magnet so that the anchor plate is firmly fixed to the platform.

Checking the fixing effect: Gently pull the anchor plate to ensure that it is firmly fixed by the magnet and will not shift during the concrete pouring process

Application scenarios of embedded anchor plate magnets

1. Industrial machinery and automation

In automated production lines, equipment parts need to be frequently replaced or adjusted. Embedded anchor plate magnets can quickly fix sensors, fixtures or protective covers, reduce downtime and improve production efficiency.

2. Building and steel structure

In construction, temporary fixing of steel beams, formwork or scaffolding is a challenge. Traditional welding or bolting is time-consuming and labor-intensive, while precast concrete embedded anchor plate magnets can be quickly installed and removed, greatly improving construction efficiency.

3. Logistics and warehousing

In warehousing systems, shelves, conveyor belts or sorting equipment need to be flexibly adjusted. Embedded magnet anchor plates can easily fix and move equipment to adapt to different logistics needs.

4. Automobile manufacturing and maintenance

During automobile assembly or maintenance, some parts need to be temporarily fixed. Magnetic anchor plates provide a non-damaging, reusable solution that avoids scratches or deformation caused by traditional clamps.

Why choose embedded anchor plate magnets?

🔹 Save time - no complicated installation is required, magnetic suction is ready to use, improving work efficiency.

🔹 Reduce costs - reduce the use of welding, drilling or special clamps, and reduce maintenance costs.

🔹 Enhance flexibility - suitable for dynamic adjustment needs and adapt to changing working environments.

🔹 Safe and reliable - high-strength magnets and stable anchoring structure ensure long-term use without loosening.