-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

The Significant Impact of Precast Concrete Formwork Magnets on Prefabricated Component Wall Panes

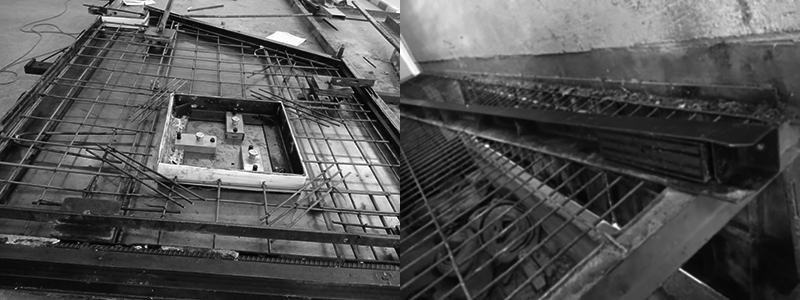

Dec 04, 2024In the realm of prefabricated construction, the innovative use of precast concrete components has revolutionized the industry, offering enhanced speed, accuracy, and durability. Among the crucial elements driving this transformation is the utilization of precast concrete shuttering magnets, specifically designed to optimize the creation of prefabricated member wall panels.

Efficiency and Reliability:

The introduction of precast concrete shuttering magnets has greatly accelerated the construction timeline, allowing for faster assembly and disassembly of formwork. With their strong magnetic force, these magnets securely hold the formwork in place, eliminating the need for cumbersome and time-consuming clamping systems. This not only expedites the construction process but also ensures precise alignment and reduces the risk of misalignment or shifting. By streamlining the workflow, precast concrete shuttering magnets significantly enhance construction efficiency and reliability, enabling projects to be completed within shorter timeframes while maintaining optimal quality.

Flexibility and Customization:

One of the key advantages of using precast concrete shuttering magnets is the flexibility they offer in design and customization. With the magnets securely holding the formwork in place, complex shapes and intricate architectural details can be easily achieved. The prefabrication process allows for flexibility in creating unique wall panel designs, meeting the specific requirements of different projects. The combination of precast formwork magnets and precast concrete formwork empowers architects and engineers to experiment with various geometries, resulting in aesthetically pleasing structures.

Energy Efficiency and Environmental Sustainability:

In an era of growing environmental concerns, precast concrete formwork and shuttering magnets provide a sustainable alternative to traditional construction methods. Precast manufacturing reduces the amount of material waste on the construction site and improves the precision of the production process. The use of precast formwork magnets eliminates the need for drilling or anchoring, minimizing damage to the environment. Additionally, precast concrete structures have excellent insulation properties, improving energy efficiency by reducing heating and cooling requirements.