-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

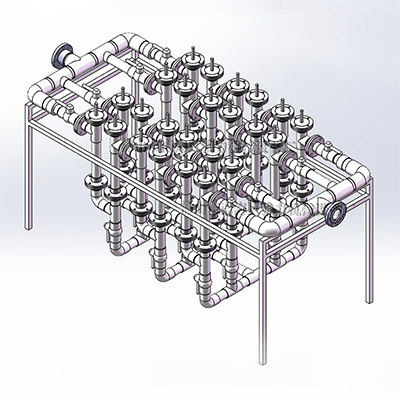

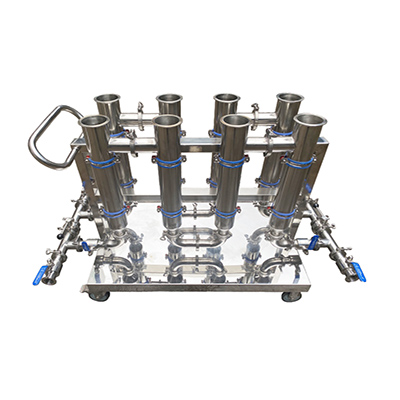

Slurry iron removal trolley: Efficiently solve the problem of iron impurities in mining, ceramics, chemical and new energy industries

Mar 30, 2025In the production process of mining, ceramics, chemical and new energy industries, iron impurities in raw materials often affect product quality, damage equipment, and even cause production interruptions. How to efficiently and conveniently remove iron contaminants from slurry? The Slurry Iron Removal Trolley is a professional equipment designed to solve this problem. It combines strong magnetic iron removal technology and mobile operation advantages to provide efficient solutions for various slurry treatment scenarios.

Core advantages of slurry iron removal trolley

✅ Efficient iron removal - electromagnetic slurry iron remover and permanent magnetic slurry iron remover adopt high-strength permanent magnetic or electromagnetic iron removal technology, which can quickly absorb impurities such as iron filings and rust in the slurry.

✅ Flexible mobility - the movable slurry iron removal trolley is equipped with universal wheels or track design, which can be easily moved to different production links to meet the needs of multiple stations.

✅ Easy operation - one-button control, easy cleaning, reduced manual intervention, and improved production efficiency.

✅ Corrosion-resistant design - stainless steel or special coating is used, suitable for harsh environments such as humidity, acid and alkali.

✅ Low maintenance cost - low operating cost The slurry iron removal trolley has a simple structure, strong durability, and is economical and efficient for long-term use.

Typical application environment of slurry iron removal trolley

1. Mining and mineral processing industry

During the process of ore crushing, grinding and flotation, iron filings produced by crusher wear or iron impurities in the original ore are often mixed into the slurry. These impurities not only affect the efficiency of mineral processing, but may also damage equipment such as pumps and pipelines.

📌 Solution: The slurry iron removal trolley can be installed at key positions such as the ball mill outlet and in front of the flotation tank to absorb iron impurities in real time, protect subsequent equipment and improve the purity of the concentrate.

2. Ceramics and building materials industry

Iron impurities in ceramic slurry and glaze will cause black spots and color differences in the product, seriously affecting the quality of the finished product. Traditional filtering methods are inefficient and difficult to completely remove fine iron particles.

📌 Solution: The iron removal trolley can be integrated next to the mixing tank and the conveying pipeline to dynamically absorb iron pollutants to ensure the purity of the slurry and improve the whiteness and finished product rate of the ceramic.

3. Chemical and environmental protection industry

In the production process of chemical slurry (such as titanium dioxide, calcium carbonate, etc.), iron pollution will affect the efficiency of chemical reactions and product performance. In addition, iron-containing sludge in sewage treatment also needs to be effectively separated.

📌 Solution: The slurry iron removal trolley in the chemical industry can be used at the feed end of the reactor or in the wastewater treatment link to reduce iron ion interference and optimize the production process.

4. Food and pharmaceutical industry

Some food additives and pharmaceutical raw materials have strict requirements on iron content in slurry, and exceeding the standard will affect product safety and stability.

📌 Solution: The iron removal trolley made of food-grade stainless steel meets hygiene standards and ensures that the raw materials are free of iron pollution.

5. New energy industry

The application of iron removal trolleys for lithium battery positive electrode slurry in the battery industry is mainly concentrated in the production process of lithium-ion batteries, especially in the slurry preparation and coating links

📌 Solution: After the preparation of the positive and negative electrode slurries, the slurry needs to be iron-removed to remove possible iron impurities. Before the slurry is transported to the coating machine, the battery slurry iron removal trolley is used to perform the final purification of the slurry. This step can effectively prevent iron impurities from contaminating the pole pieces during the coating process.

Why choose a slurry iron removal trolley?

🔹 Improve product quality - reduce defects caused by iron impurities and increase product qualification rate.

🔹 Protect production equipment - avoid iron filings from wearing key components such as pumps and valves, and extend equipment life.

🔹 Reduce labor costs - automatic iron removal, reduce the frequency of manual cleaning, and improve production efficiency.

🔹 Adapt to complex environments - dustproof, waterproof, and corrosion-resistant design, suitable for high humidity and high pH scenes.