-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Precast concrete: the new star of modern architecture

Feb 26, 2025In the field of modern construction, precast concrete is gradually becoming a revolutionary building material. It not only improves construction efficiency, but also significantly improves building quality. With the continuous advancement of process technology and the application of high-tech equipment such as Precast Concrete Magnet, the future development prospects of precast concrete will be even broader. Whether it is residential buildings, public buildings or infrastructure, precast concrete will play an important role and promote the construction industry to a higher level.

What is precast concrete?

Precast concrete is a type of concrete component that is prefabricated in a factory and then transported to the construction site for assembly. Compared with traditional on-site cast concrete, precast concrete has higher quality control, faster construction speed and better environmental performance. This material is widely used in residential construction, public buildings, infrastructure and industrial construction.

The main ingredients of precast concrete are similar to those of conventional concrete, but the proportions and additives may differ.

1. Cement: acts as a binder to hold other materials together.

2. Aggregates: include sand and gravel, providing strength and volume to concrete.

3. Water: reacts chemically with cement to form a hardened body.

4. Additives: such as water reducers, retarders, etc., used to improve the working properties and durability of concrete.

The manufacturing process of precast concrete is a complex and sophisticated system engineering, involving multiple steps such as design, mold preparation, concrete mixing, pouring, maintenance, demoulding, quality inspection, transportation and installation. Each step requires strict control and management to ensure the quality and performance of the final product. With the continuous advancement of technology, the manufacturing process of precast concrete will be more efficient and environmentally friendly, bringing more innovation and development to the modern construction industry.

1. Design and planning, this step includes:

- Architectural design: Design the shape, size and structure of the component according to the needs of the construction project.

- Mold design: Make high-precision molds according to the design drawings of the component to ensure the accuracy and consistency of the component.

- Material ratio: Determine the ratio of concrete, including the ratio of cement, aggregate, water and additives to meet the requirements of strength, durability and working performance.

2. Mold preparation is a vital tool in the manufacturing process of precast concrete.

- Mold making: Make molds using steel, wood or other materials according to the design drawings. The mold must have high precision and good sealing to ensure the accuracy of the size and shape of the component.

- Mould treatment: Before pouring concrete, the mould needs to be cleaned and coated with a release agent to facilitate the subsequent demoulding process.

3. Concrete mixing is a key step to ensure uniform mixing of materials.

- Material weighing: Accurately weigh cement, aggregate, water and additives according to the predetermined ratio.

- Mixing: Put the weighed materials into the mixer and mix them thoroughly to ensure the uniformity and working performance of the concrete. The mixing time, speed and sequence need to be strictly controlled.

4. Concrete pouring, pour the mixed concrete into the mould, this step needs to pay attention to the following points:

- Layered pouring: For larger components, layered pouring may be required to ensure the density and uniformity of the concrete.

- Vibration: Use a vibrator to vibrate the poured concrete to remove bubbles and improve the density and strength of the concrete.

- Surface treatment: After pouring, the concrete surface is smoothed and treated to ensure its flatness and aesthetics.

5. Curing. After the concrete is poured, it needs to be cured to ensure its hardening and strength development.

- Natural curing: curing in the natural environment, suitable for conditions with suitable temperature and humidity.

- Steam curing: accelerating the hardening process of concrete through steam, suitable for conditions that require rapid demoulding and production. Steam curing can significantly shorten the curing time and improve production efficiency.

- Wet curing: keep the surface of the concrete moist by spraying water or covering it with a wet cloth to prevent cracking.

6. After the concrete reaches sufficient strength, demoulding is carried out.

- Mold removal: carefully remove the mold to avoid damaging the components.

- Surface treatment: perform necessary surface treatment on the components after demoulding, such as repairing defects, polishing, etc.

7. Quality inspection. The components after demoulding need to undergo strict quality inspection to ensure that they meet the design requirements and standards. :

- Dimension inspection: measure the dimensions of the components to ensure that they meet the design drawings.

- Strength test: test the compressive strength of the components through pressure tests and other methods.

- Appearance inspection: Check whether there are cracks, bubbles and other defects on the surface of the components.

8. Transportation and installation. Components that pass the quality inspection will be transported to the construction site for installation.

- Transportation: Use special transportation vehicles to ensure that the components are not damaged during transportation.

- Installation: According to the construction drawings, use lifting equipment to install the components to the designated location, and fix and connect them.

The process technology of precast concrete is the key to its success.

1. Mould technology: Use high-precision moulds to ensure that the size and shape of the components are accurate.

2. Automated production: Mix, pour and maintain concrete through automated equipment to improve production efficiency and consistency.

3. Steam curing: Use steam to accelerate the hardening process of concrete and shorten the production cycle.

4. Quality control: Perform strict quality inspections in a factory environment to ensure that each component meets the standards.

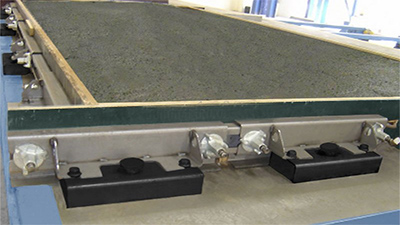

The application of Precast Concrete Magnet in precast concrete significantly improves the strength, durability, working performance and construction efficiency of concrete through the action of magnetic field. This technology not only improves the quality and performance of precast concrete, but also brings environmental protection and energy-saving benefits, and is widely used in various construction and infrastructure projects. With the continuous advancement of technology, Precast Concrete Magnet will play a more important role in the field of precast concrete and promote the construction industry to a higher level. It has a wide range of applications Application performance:

Residential buildings: used for walls, floor slabs and other components to improve building quality and durability.

Public buildings: such as schools, hospitals, etc., to ensure structural safety and long-term use.

Infrastructure: bridges, tunnels, etc., to enhance the compressive and tensile properties of the structure.

Industrial buildings: factories, warehouses, etc., to improve the stability and service life of the building.