-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Important process in prefabrication: galvanizing

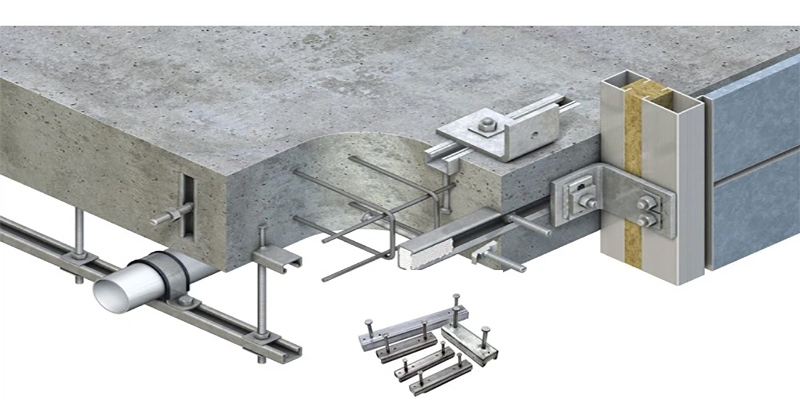

Mar 06, 2025In the field of modern construction and engineering, prefabricated components are increasingly used. Prefabricated components can not only improve construction efficiency, but also ensure project quality. However, prefabricated components often face corrosion problems during use, especially in harsh environmental conditions. In order to solve this problem, galvanizing is widely used in the anti-corrosion treatment of prefabricated components.

What is galvanizing?

Galvanizing is a process that prevents corrosion by covering the metal surface with a layer of zinc. Zinc, as an active metal, can undergo oxidation reaction before iron or steel, thereby protecting the substrate from corrosion. There are two main types of galvanizing processes: hot-dip galvanizing and electro-galvanizing.

1. Hot-dip galvanizing: The prefabricated component is immersed in molten zinc liquid to form a layer of zinc-iron alloy and pure zinc on its surface. This process is suitable for large components and can provide a thicker zinc layer with excellent anti-corrosion properties.

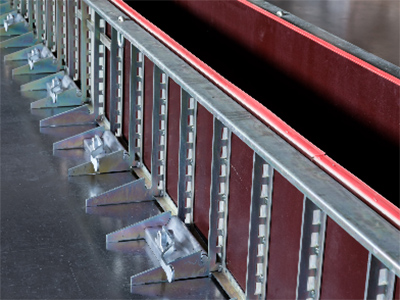

2. Electro-galvanizing: A layer of zinc is deposited on the surface of the prefabricated component through electrolysis. This process is suitable for small components or occasions where a thinner zinc layer is required, and has a better surface finish.

Engineering steps for galvanizing prefabricated components

1. Surface treatment: This is the most critical step in the galvanizing process. The prefabricated components need to be thoroughly cleaned before galvanizing to remove oil, rust and other impurities. Common surface treatment methods include sandblasting, pickling, etc.

2. Coating treatment: After surface cleaning, the prefabricated components need to be treated with coating agents. Coating agents are usually a mixed solution of ammonium chloride and zinc chloride, which can prevent the components from oxidizing before being immersed in the zinc liquid.

3. Hot-dip galvanizing: The prefabricated components that have been surface treated and coated with coating agents are immersed in molten zinc liquid for a certain period of time to allow the zinc liquid to fully react with the substrate to form a zinc-iron alloy layer and a pure zinc layer.

4. Cooling: After galvanizing, the prefabricated components need to be removed from the zinc liquid and cooled. The cooling method can be natural cooling or water cooling, depending on the process requirements.

5. Post-processing: After cooling, the prefabricated components may need some post-processing, such as removing excess zinc slag, trimming the surface, etc., to ensure the appearance and quality of the components.

The significant role of galvanizing on prefabricated components

1. Anti-corrosion protection: The galvanized layer can effectively isolate the contact between the prefabricated components and the external environment, preventing the corrosion of the substrate by oxygen and moisture. When the zinc layer is damaged, it can continue to protect the substrate through sacrificial anodes, extending the service life of the components.

2. Improve durability: The galvanized layer has excellent wear resistance and impact resistance, can effectively resist external physical damage, and improve the durability of prefabricated components.

3. Reduce maintenance costs: Due to the long-term anti-corrosion effect of the galvanized layer, prefabricated components do not need frequent anti-corrosion maintenance during use, which greatly reduces maintenance costs.

4. Aesthetics: The galvanized layer has a silvery-white luster, which can improve the appearance quality of prefabricated components and is suitable for occasions with high aesthetic requirements.

5. Environmental protection: The zinc used in the galvanizing process is a recyclable material that meets environmental protection requirements. In addition, the galvanized layer does not release harmful substances during use and is environmentally friendly.

Tags :