-

Email Us

sale@lscmagnetics.com -

Contact Number

+86 -13559234186

Email Us

sale@lscmagnetics.com

Contact Number

+86 -13559234186

Comprehensive understanding: Flange, an important component of Magnetic Liquid Trap

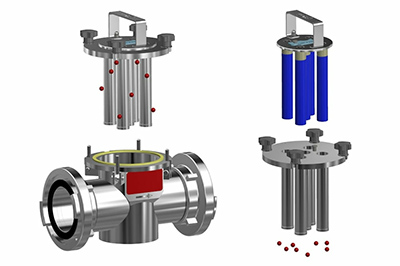

Mar 21, 2025In the liquid handling industry, Magnetic Liquid Trap is a device used to remove ferromagnetic impurities from liquids and is widely used in the fields of chemical, food, and medicine. As an important component of the device, flanges play a vital role in the connection, sealing, and stable operation of the equipment.

Function of Magnetic Liquid Trap Flange

The flange in Magnetic Liquid Trap is mainly used to connect the inlet and outlet pipes of the equipment, and ensure that the equipment can efficiently filter ferromagnetic impurities in the liquid during operation. Its specific functions include:

1. Connection function: connect the Magnetic Liquid Trap to the pipeline or other equipment to ensure smooth passage of liquid.

2. Sealing function: prevent liquid leakage and ensure that the equipment operates in a closed environment.

3. Support function: provide stable support for the equipment and reduce vibration and noise during operation.

4. Easy maintenance: The flange connection method is easy to disassemble and install, and convenient for cleaning and maintenance of the equipment.

Material selection for magnetic liquid trap flanges

The material of magnetic liquid trap flanges should be selected according to the properties of the liquid, the working environment and the hygiene requirements. Common materials include:

1. Stainless steel - corrosion-resistant, high-temperature-resistant, and good hygiene performance. Applicable scenarios: food, medicine, chemical industry and other industries with high requirements for hygiene and corrosion resistance.

2. Carbon steel - high strength and low cost. Applicable scenarios: ordinary industrial environments, such as filtration of non-corrosive liquids.

3. Plastic or composite materials - light weight, corrosion-resistant, but low strength. Applicable scenarios: light industry or highly corrosive environments.

4. Alloy steel - high strength and wear resistance. Applicable scenarios: filtration of high-load or high-temperature liquids.

Magnetic Liquid Trap is widely used in industries that need to remove ferromagnetic impurities from liquids, such as:

- Food industry: remove metal impurities from liquids such as juice and milk to ensure food safety.

- Chemical industry: separate iron contaminants from chemicals to improve product purity.

- Pharmaceutical industry: remove metal particles from liquid medicine to ensure the quality of medicine.

- Lubricant treatment: remove metal debris from lubricants to extend the service life of equipment.

How to maintain the Magnetic Liquid Trap flange? Proper maintenance can extend the service life of the flange and ensure stable operation of the equipment. The following are maintenance suggestions:

1. Regular inspection - Check whether there are cracks, corrosion or wear on the flange surface, and replace it in time if any problems are found.

- Check whether the bolts are loose and ensure that the connection is tight.

2. Cleaning and maintenance - Regularly clean the dirt and impurities on the flange surface to prevent corrosion.

- For stainless steel flanges, special cleaning agents can be used to keep the surface smooth.

3. Anti-corrosion treatment - In corrosive environments, anti-rust oil or anti-corrosion coating can be applied to the flange surface.

- Regularly check the integrity of the anti-corrosion layer and repair it in time.

4. Lubrication maintenance - Regularly lubricate the bolts and sealing surfaces at the flange connection to prevent rust and wear.

5. Replace seals - Regularly check seals (such as gaskets) and replace them in time if they are aged or damaged to prevent leakage.

Although the flange in the Magnetic Liquid Trap is a small component, it plays an irreplaceable role in the operation of the equipment. Through scientific material selection and proper maintenance, the operating efficiency of the equipment can be significantly improved, the service life can be extended, and the maintenance cost can be reduced. Whether it is the food, chemical or pharmaceutical industry, choosing the right flange material and implementing effective maintenance measures can bring higher production benefits and better product quality to the company.